In the sophisticated field of manufacturing, packaging plays a pivotal role. It not only safeguards and preserves products but also acts as the primary touchpoint for consumers. With technological advancements, a diverse range of packaging machinery has been developed, each tailored for specific functions and purposes. This encompasses filling machines, sealing machines, strapping machines, pallet wrappers, carton sealers, container sealers, and industrial weighing systems. This article provides a comprehensive overview of the myriad packaging machinery options, underscoring their importance and spotlighting the top choices in the industry.

How Do Packaging Machines Affect Your Business?

Consider a scenario devoid of advanced packaging equipment such as vertical form fill systems, banding machines, or even the fundamental heat sealer. Without the automation benefits of robotics—take the robotic arm for instance—or the pinpoint accuracy of programmable logic controllers, businesses would grapple with increased expenses, extended production durations, and heightened risk of errors. The financial implications of relying solely on manual operations would rise considerably, emphasizing concerns related to processes like stretch or shrink film wrapping. Continuous oversight would be required for wrap delivery systems, and ensuring uniform product packaging, especially in extreme temperature conditions, would present significant hurdles.

Modern packaging machinery, whether for polyethylene-based products or those developed by external engineering entities, contribute vastly in terms of speed and precision. They guarantee that items, be it in plastic shell packaging or special promotions in cardboard containers, epitomize quality in the market. Such equipment minimizes waste, boosts visual appeal, and often emerges as the optimal choice, independent of a business’s geographic positioning or its varied supplier affiliations.

To summarize, the transition from manual labor to the prowess of contemporary equipment is paramount. Packaging machinery profoundly impacts a firm’s financial health, brand reputation, and consumer contentment, solidifying their role as vital assets in our dynamic commercial landscape.

6 Advantages of Packaging Machinery

Packaging machinery has transformed the product distribution and sales process. Here are the primary benefits of employing such machinery:

- Enhanced Efficiency: Packaging machinery significantly accelerates the product packaging process. These automated systems can handle thousands of products in a fraction of the time it would take manual labor, leading to increased production capabilities and ensuring businesses can address market demands promptly.

- Uniformity & Standardization: Machines consistently produce packages with uniform weight, size, and sealing. This standardized packaging boosts brand credibility and ensures consumers receive a consistent product quality.

- Economic Benefits: Although the initial outlay for packaging machinery might be considerable, the long-term financial benefits are noteworthy. Automation reduces labor costs and often optimizes material usage, cutting down waste and raw material expenses.

- Safety Enhancements: Automation minimizes worker interaction with potentially risky packaging operations, reducing the risk of injuries. Additionally, machinery guarantees products are sealed in a hygienic setting, vital for items like food and pharmaceuticals.

- Versatility: Contemporary packaging equipment is inherently versatile. Many can be modified or adapted to cater to varied products or packaging styles, letting businesses broaden their offerings without substantial new machine investments.

- Minimized Human Error: Properly maintained and calibrated machinery is less prone to mistakes compared to manual labor. This precision results in decreased waste and a superior end product.

What Industry Needs to Use Packaging Machines?

Packaging machinery holds a paramount position in various industries, acting as the backbone for product safety, efficiency, and presentation. It not only ensures that items are protected and stored correctly but also that they are presented in a manner consistent with brand values and consumer expectations. The following provides a comprehensive overview of industries where packaging machinery plays an indispensable role:

- Food and Beverage: Advanced packaging machinery is crucial in streamlining processes such as bottling, sealing, and labeling, catering to a diverse range of products from beverages to snack items.

- Pharmaceuticals: The health sector necessitates secure and sanitary packaging solutions. Cutting-edge packaging machinery ensures accurate dosing and tamper-proof seals for medicines, safeguarding consumer health.

- Cosmetics and Personal Care: When it comes to products like creams and cosmetics, accuracy in dosage and aesthetic appeal are of utmost importance. This is realized using sophisticated packaging equipment tailored for the sector.

- Agriculture: The agricultural sector relies on packaging equipment for the systematic bagging and preservation of seeds, grains, and assorted agricultural goods.

- Chemicals: Whether it’s household cleaning agents or large-scale industrial chemicals, stringent packaging standards are essential. Proper machinery ensures both user safety and regulatory adherence.

- Pet Food: Ensuring the longevity and quality of pet food requires sturdy packaging solutions. Advanced mechanisms work to seal pet food efficiently, reducing contamination risks and maintaining freshness.

- Confectionery: To ensure that sweet treats like chocolates and candies remain fresh and are presented enticingly, specialized equipment is employed.

- Tobacco: The tobacco industry utilizes specialized packaging methods, particularly for products like cigarettes, to guarantee prolonged freshness and optimal storage.

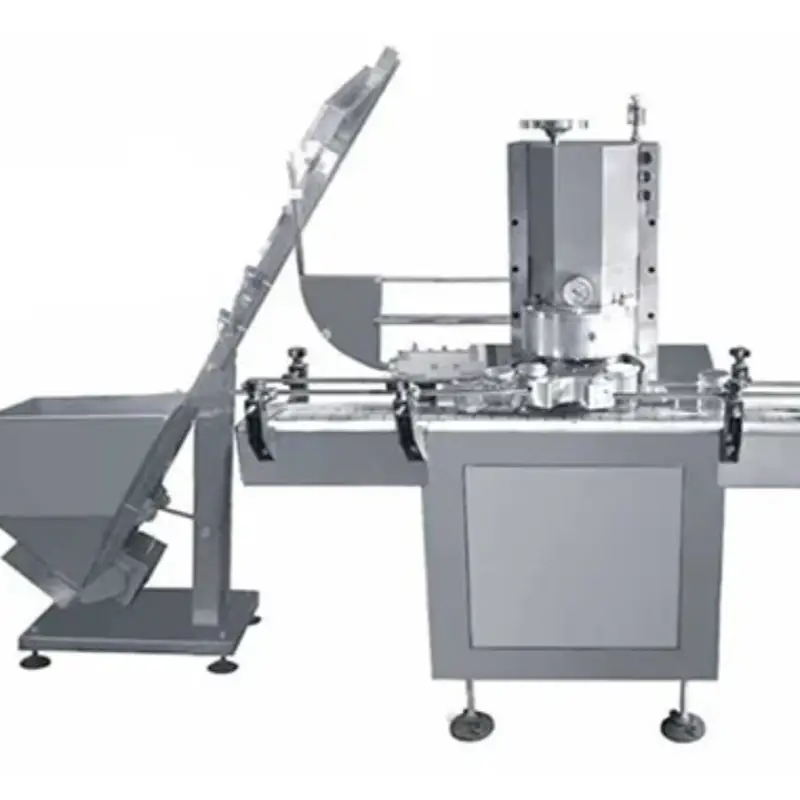

Filling Machine

In the current packaging industry, filling machines are essential for the production process. They are built to fill containers with liquid, powder, or granular products in a clean, accurate, and efficient way. The type of material and the packaging requirements usually divide filling machines into three main groups: liquid filling machines, powder filling machines, and granule/solid filling machines. Every type is designed for a specific reason and offers different benefits during the packaging process.

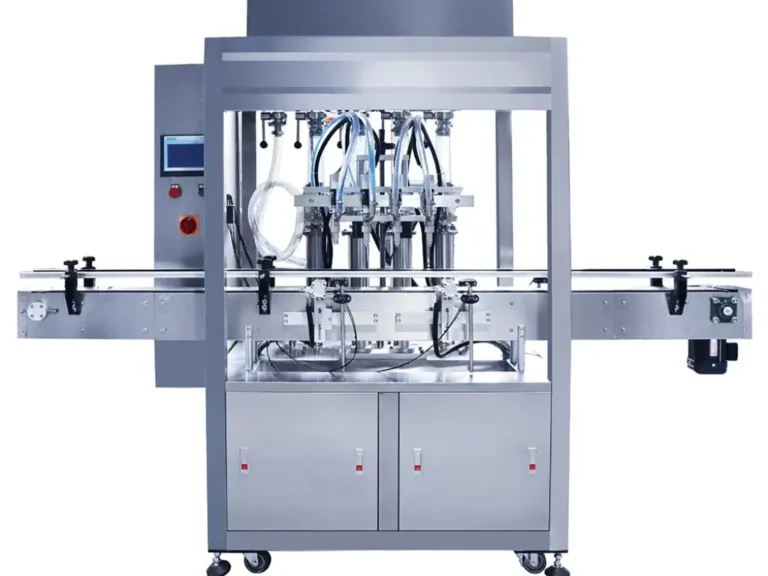

Liquid Filling Machines

Liquid filling machines are common in the food and beverage, cosmetics, pharmaceutical, and chemical industries. They are most often used for milk, juices, edible oils, sauces, shampoo, and perfumes. Based on how thick and how fast the product flows, these machines can be filled using gravity, pistons, or vacuum methods.

- Gravity fillers are best suited for thin liquids like water or juice.

- Piston fillers are used for thick products such as ketchup, honey, and lotions.

- Vacuum fillers ensure that the fills are clean and free of foam, which is ideal for wine and pharmaceutical liquids.

They help prevent products from spilling, keep the area clean (especially important for food packaging), and ensure that every container is filled the same way. Using liquid filling machines on an automatic packaging line helps the company produce more, use fewer workers, and improve the quality of its products. These devices also make high-throughput systems more affordable.

Powder Filling Machines

For materials such as flour, cocoa, protein powders or baby formula, powder filling machines are necessary. Most of these machines rely on auger-based dosing which uses a rotating screw to measure and put the correct amount of powder into containers. Being precise is very important, especially in sectors such as pharmaceuticals and infant nutrition.

Today’s powder fillers are equipped with dust extraction and anti-static features that help keep the process clean and consistent. With heat sealers or form-fill-seal machines, they can produce packaging that is both secure and shows if it has been opened. No matter if you use them for food or chemicals, these machines are built to ensure your packing is both precise and clean.

Granule/Solid Filling Machines

If you need to package coffee beans, cereal, nuts, pet food, or candy, granule or solid filling machines are the best option. They rely on multi-head weighers, volumetric cup fillers, or gravity feeding systems to correctly fill products into containers or pouches.

They are commonly used with vertical form fill seal (VFFS) machines or together with premade pouches to produce bags that are easy for consumers to use, such as pillow bags or stand-up pouches. A large roll of film is used in packaging with plastic film, which is both affordable and quick, and it provides strong sealing. They help pack food products efficiently, require less labor, increase how much that can be processed, and ensure the same quality every time.

Whether you’re handling powders, liquids, or solids, choosing the right types of packaging machines is crucial for ensuring efficiency, cleanliness, and compliance in your packaging operations.

About Filling Machines You Also Need to Know: What is a Filling Line for Bottles and Cans?

Sealing Machine

Sealing is an important part of packaging because it affects both the quality and safety of the product. No matter if you’re sealing liquids, powders, or solid foods, the proper sealing machine helps keep the contents safe from contamination, leaks, and spoilage. The following are the main types of sealing machines found in today’s packaging lines.

Heat Sealers

Heat sealers are commonly found in packaging systems, mainly in vertical form fill seal (VFFS) machines, where heat and pressure join layers of plastic or other thermoplastic materials through a heat seal process. This method creates a tight seal that is necessary to keep the product safe, clean, and unspoiled in food and drug packaging. Sealing reliably is important for both the appearance, the hygiene, and the compliance of products on automated packaging lines.

Induction Sealers

Induction sealers are designed to create seals that show if a product has been opened, and they are used for bottles and jars in beverages, sauces, pharmaceuticals, and cosmetics. Electromagnetic induction is used to heat a foil liner inside the cap, which seals the container opening tightly. The outcome is a tight, secure, and leak-proof seal that keeps products safe and fresh for longer and also makes it easy to see if the package has been opened—a key point for both consumer trust and meeting regulations.

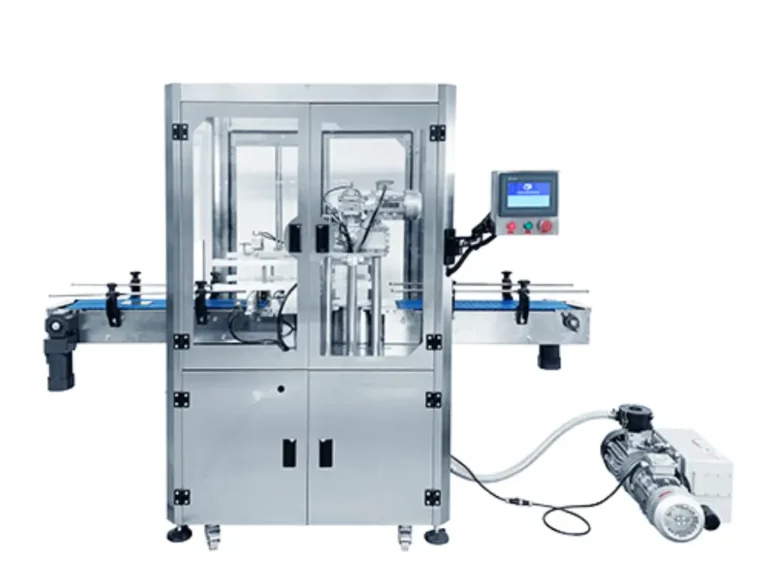

Capping Machines

Capping machines help to automate the process of putting caps on bottles with the same amount of torque and speed. These machines can handle any type of closure, including screw caps, press-on lids or snap-fit closures, with great precision and speed which helps reduce both labor and error. Because they are used in high-speed production, capping machines are found in many industries, including food, beverages, pharmaceuticals, and industrial chemicals, to ensure that packages are leak-proof and the product is not damaged.

Vacuum Sealers

Vacuum sealers take out the air from the packaging and create an airtight seal, which helps to stop oxidation and keep food fresh for longer. Because these machines reduce the amount of oxygen, they help maintain the taste, texture, and nutrients in meats, cheeses, coffee, and dry goods. Vacuum sealers are often used in food processing and kitchens, and they are also found in industrial machines that must keep food sealed and clean for long-term storage and transportation. It helps to reduce food waste and improve the safety of products all along the supply chain.

Wrapping Machines

Today, packaging operations rely on wrapping machines to secure, bundle, and present products in a tidy way. They use a flexible plastic film, heated, stretched, or moved continuously, to make a strong outer layer that helps keep the product safe, easy to handle, and branded. Wrapping equipment is essential for packaging both individual snack bars and entire pallets of consumer goods in both mid-line and end-of-line packaging.

Shrink Wrappers

Heat is used by shrink wrappers to tightly cover products with plastic film, which makes the packaging both secure and easy to identify if opened. Shrink wrappers are often used with food trays, bottles, consumer goods, and multipacks, and they usually operate together with a shrink tunnel that uses hot air to make the film shrink evenly. It allows for attractive packaging, safer products, and stable items during transit. Because it is cost-effective, shrink wrapping is widely used in retail and distribution.

Stretch Wrappers

Stretch wrappers are mainly used to secure and unitize palletized loads by wrapping stretch wrap around them. This step is necessary to keep products safe during transport and to avoid damage in large-scale logistics. With both semi-automatic and fully automatic options, stretch wrappers help cut labor costs and reduce labor requirements while ensuring loads are secure, so they are important in end-of-line packaging. They are often found in food processing, beverage, and consumer goods industries, where moving large quantities safely is very important.

Flow Wrappers (HFFS)

Flow wrappers, which are also called HFFS machines, wrap individual items, including snacks, medical products, or small hardware, in a continuous flow of packaging. These machines wrap a product using just one roll of film, seal it on both ends, and cut it into individual packs that are often in the pillow pack style. Flow wrappers are fast, accurate, and can be used with different types of food packaging. Because they are efficient and hygienic, they are perfect for packaging on any type of production line.

Form-Fill-Seal Machines (FFS)

Among all packaging machines, Form-Fill-Seal (FFS) machines are some of the most efficient and automated. The entire packing process is simplified by using these systems, which form the package, add the product, and seal it all at once. FFS machines are popular in food processing, pharmaceutical, and consumer goods because they need less labor, improve hygiene, and increase production speed, which helps companies save on costs.

Vertical FFS (VFFS)

VFFS machines are perfect for packaging powders, granules, liquids, and small solids like sugar, coffee, rice, and soups. These machines pull down a roll of film vertically to form a pouch, dispense the product, and seal the bag in the same direction. VFFS systems are often found in food packaging machines, mainly for making pillow bags, stand-up pouches, or gusseted bags. Thanks to their small size and fast operation, they can be used in both small and large packaging factories.

Horizontal FFS (HFFS)

In comparison, Horizontal Form-Fill-Seal (HFFS) machines are ideal for products that are solid or fragile and need to be placed horizontally, such as chocolate bars, medical items, or dairy products in trays. They take a single roll of film, form it into packages horizontally, insert the product, seal them, and cut them apart. HFFS machines are commonly used for premade pouches or flow packs and provide a lot of flexibility for design and labeling. Because they can be controlled by programmable logic controllers, they are a leading choice for high-volume packaging tasks.

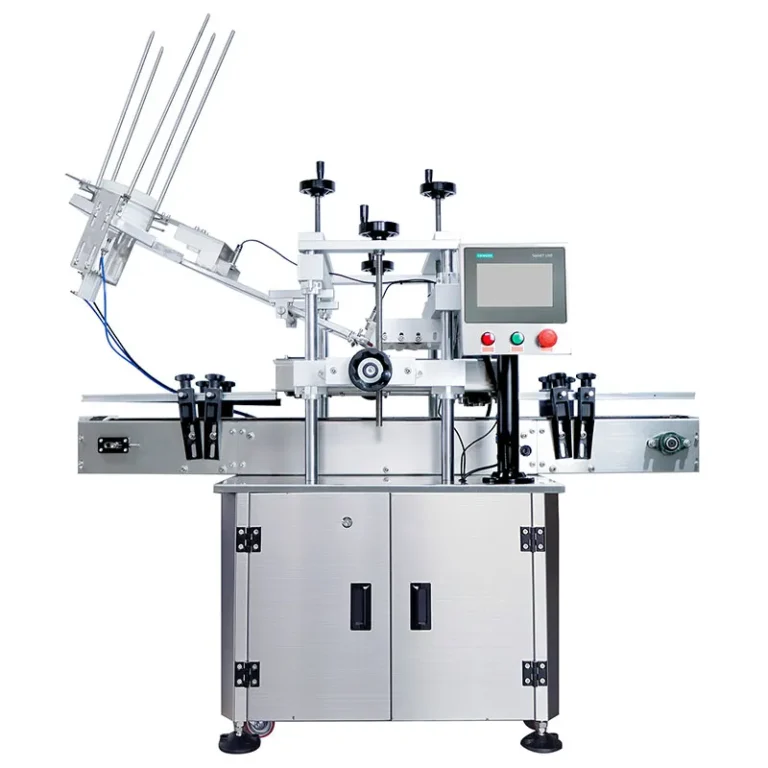

Labeling Machines

For any modern packaging line, accurate and efficient labeling is necessary for ensuring safety, following rules, and tracing products. Various package shapes and materials are labeled with QR codes, date codes, barcodes, and branding by labeling machines. No matter if you’re labeling juice, pet supplements, or hardware, the right labeling system helps you maintain consistency, speed, and obey regulations. Automated labeling saves money and also makes production and packaging more efficient and attractive in high-demand consumer goods sectors.

Flat and Side Labelers

Flat and side labelers are built to attach labels to the sides or flat areas of rectangular or square packages. Many industries that deal with premade bags, blister packs, or food packaging use these machines for cartons, boxes, and flat pouches. They are designed with adjustable applicators and usually include vision systems that help them place items accurately at high speed. Side labeling is important for both showing products and handling logistics, as scannable labels are needed for stock control and putting items on shelves.

Round Bottle Labelers

Round bottle labelers are designed to apply labels to bottles, jars, and tubes, which are often found in food, cosmetics, and pharmaceutical packaging. The machines apply labels to the container’s sides without wrinkles, so the QR codes, branding, and required details are neatly aligned. Round labelers are suitable for both glass bottles of sauces and plastic containers of dairy products, and can be added to both manual and automatic lines in packaging equipment.

End-of-Line Packaging Machinery

At the end of the packaging line, machines called end-of-line packaging machinery help prepare products for storage, distribution, and display in stores. They make it possible to handle packed goods automatically, by organizing, sealing, moving, and stacking them, which reduces the need for manual work, increases the speed of production, and guarantees the quality of the products. Many industries, such as food processing and consumer goods manufacturing, depend on such systems to reduce labor costs and improve how they work.

Conveyors

The movement of products through the packaging process is made possible by the conveyors that are the main support of any production line. They can be adjusted for speed, direction, and the type of load, suitable for filling pouches or wrapping pallets. Conveyors are used to move dairy products through vertical form fill seal systems and boxed consumer goods to case packers, making the line more efficient, reducing errors, and requiring less manual help.

Case Packers

Case packers make it possible to pack products into boxes or cartons automatically, which greatly increases both speed and accuracy. In food packaging, beverage production, and pharmaceuticals, these automatic machines are important because they help pack cases uniformly, which improves stacking and makes transport safer. Case packers help cut costs and improve palletizing by reducing mistakes and making the best use of available space, all while keeping products safe and of high quality.

Case Sealers

After products are placed in cartons, case sealers close and seal the boxes with tape or heat sealing. They make sure every case is sealed the same way, so nothing can be opened or damaged during shipment. Case sealers in fast packaging lines eliminate the problems of manual sealing and help the line run smoothly. Using them in automated systems helps keep packaging costs low and ensures all types of packaging machinery produce consistent results.

Palletizers

Palletizers are designed to arrange finished cases or products in a fixed, secure pattern on pallets. In any facility that produces a lot, these machines are necessary because they make work easier for staff and ensure goods are transported safely. Palletizers are capable of handling shrink-wrapped trays, cartons, and plastic film-wrapped bundles, no matter of whether they are robotic or conventional. They help businesses by making logistics more efficient, reducing injuries at work, and keeping the cost of packaging down over the years.

How to Maintain and Clean Packaging Machines?

Packaging machines, like any other industrial equipment, require regular maintenance and cleaning to ensure they function optimally for your particular needs and achieve peak performance. Proper maintenance not only ensures the longevity of the machine but also guarantees that the products being packaged meet the required hygiene and quality standards. A preventative maintenance strategy is an extra cost to consider when purchasing packaging machinery, but it’ll save thousands of dollars. Here’s a comprehensive guide on how to maintain and clean packaging machines and address their specific energy requirements based on their geographical location.

- Routine Inspection: Begin with a daily or weekly inspection, depending on the machine’s usage frequency. Check for any visible signs of wear and tear, such as loose parts, frayed wires, or any unusual noises when the machine operates. These could be early indicators of a potential problem that needs addressing before it escalates.

- Lubrication: Many parts of packaging machines require regular lubrication to function smoothly. Ensure that you’re using the right type of lubricant and applying it to the necessary components. Regular lubrication reduces friction between moving parts, preventing premature wear and tear.

- Cleaning Procedures: Dust, debris, and product residue can accumulate in various parts of the machine. It’s essential to clean these parts regularly to prevent clogging and ensure the machine operates efficiently. When cleaning, always turn off and unplug the machine. Use soft, damp cloths or brushes to clean the machine’s exterior and reach into crevices. For machines used in the food or pharmaceutical industries, ensure that the cleaning agents used are non-toxic and safe.

- Replace Worn-Out Parts: Over time, certain parts of the machine might wear out or become less effective. Regularly check components like seals, belts, and blades, and replace them when necessary. Using worn-out parts can compromise the machine’s efficiency and the quality of the packaging.

What is the Average Cost of Packaging Machines?

The price of packaging machines can change a lot depending on their type, how automated they are, and what is needed for production. You can buy entry-level packing machines such as semi-automatic sealers or small filling machines for as little as $5,000 to $15,000. The price for mid-range systems, such as compact form-fill-seal machines or standalone labeling machines, is usually between $20,000 and $50,000. Meanwhile, machines that are fully automated, such as high-speed vertical form fill seal systems or robotic palletizers, may cost over $100,000. You should remember that the total cost of equipment includes the price, installation, maintenance, training, and any time it is not working. Getting the right machine for your packaging line can help you work more efficiently, maintain a consistent product, and save on labor costs over time.

What Factors Influence the Price of Packaging Machines?

Several factors can influence the price of packaging machines, making it essential for potential buyers to understand these variables to make informed decisions. Here are some key factors:

| Factor | Description |

| Type of Machine | Different machines have varied functionalities. A simple sealing machine will generally cost less than a multifunctional filling and capping machine. |

| Automation Level | Fully automated machines with minimal human intervention are typically more expensive than semi-automatic or manual counterparts. |

| Production Capacity | High-volume, high-speed machines are generally priced higher than those designed for lower production volumes. |

| Features & Customization | Advanced features like touch screen interfaces, programmable controls, or specific customizations can increase the machine’s price. |

| Materials & Build Quality | High-quality materials and components that ensure durability and longevity will elevate the machine’s cost compared to those made with cheaper materials. |

| Brand & Manufacturer | Established and reputable brands might command higher prices due to their reliability and reputation in the market. |

| Regulatory Compliance | Machines designed to meet specific industry standards or regulations (e.g., for pharmaceuticals or food) might have additional features and certifications, leading to a higher price. |

| After-Sales Support | Extended warranties, training, maintenance services, and other post-purchase support can add to the overall cost. |

| Geographical Factors | Import duties, shipping costs, and local market conditions can influence the final price in different regions. |

| Economic Factors | Fluctuations in raw material prices, labor costs, and currency exchange rates can impact the manufacturing and, consequently, the selling price. |

What Different Types of Packaging Machinery Does a Canner Need?

Canning is a technique employed to preserve food by securely enclosing it in hermetically sealed containers, notably cans. This procedure encompasses multiple phases, each demanding specific equipment to guarantee the product’s integrity, safety, and longevity. Below is an overview of the essential packaging machinery required in the canning process:

| No. | Machine Type | Purpose Description |

| 1 | Depalletizer | Removes empty cans from pallets and aligns them for filling. |

| 2 | Can Washer | Cleans and sanitizes cans before they are filled with product. |

| 3 | Can Filling Machine | Accurately fills cans with the product (liquid, solid, or powder). |

| 4 | Can Seaming Machine | Seals the lids onto the filled cans to protect the product inside. |

| 5 | Pasteurizer | Heat treats the sealed cans to kill bacteria and extend the product’s shelf life. |

| 6 | Can Cooling Machine | Cools the cans after pasteurization to stabilize the product and prepare for labeling. |

| 7 | Can Drying Machine | Removes moisture from the cans after cooling, ensuring labels can adhere properly. |

| 8 | Can Labeling Machine | Applies labels to cans, providing product information and branding. |

| 9 | Can Coding Machine | Prints essential information like batch numbers, manufacturing, and expiration dates on the cans. |

| 10 | Can Packing Machine | Groups and packs cans into larger boxes or crates for distribution. |

| 11 | Palletizer | Stacks the packed boxes onto pallets, preparing them for transportation to retailers or distribution centers. |

| 12 | Conveyor System | Transports cans between different machines and stages throughout the canning line. |

Choosing Levapack-Can Packaging Machines Supplier

Levapack, a distinguished leader in the realm of can packaging machinery, offers a comprehensive suite of advanced solutions ranging from can filling and sealing to labeling and premade pouch packaging. Their product lineup is meticulously crafted to provide businesses with tailored solutions that address their distinct requirements.

State-of-the-Art Production Infrastructure: Encompassing a vast 2000 ㎡ area, Levapack’s manufacturing facility is a testament to technological excellence. Outfitted with cutting-edge CNC machinery such as milling machines, lathes, and grinders, it stands as a beacon of efficiency and precision. This sophisticated infrastructure not only underscores their commitment to delivering unparalleled quality but also positions Levapack as a reliable partner for large-scale orders with stringent delivery timelines.

Pioneering in Innovation: Central to Levapack’s ethos is a relentless pursuit of innovation. Their engineering brigade, boasting an enviable tenure of 14 years in can packaging machine and production line innovation, is perennially dedicated to refining existing designs and forging novel ones. Such unwavering dedication to Research & Development ensures that Levapack remains on the technology’s cutting edge, presenting businesses with state-of-the-art packaging solutions.

Customized Offerings for Diverse Enterprises: In a domain often dominated by giants, Levapack stands out by acknowledging the distinct necessities of small to medium-sized enterprises. Their versatile range of machinery is strategically developed to be adaptable, empowering smaller businesses to harness superior packaging solutions without a hefty financial burden.

Conclusion

In the sophisticated realm of manufacturing, packaging stands out as an essential component, fulfilling two pivotal functions. Firstly, it serves as a safeguard, guaranteeing that products are delivered to consumers in pristine condition, devoid of any potential harm during transportation or storage. Secondly, packaging operates as an unspoken brand ambassador. It has the potential to sway a consumer’s choice amid a plethora of options, solidifying its role as a crucial marketing tool.

For budding businesses, there are compact and cost-efficient machinery options that offer scalability and adaptability. These machines can be seamlessly upgraded or modified in line with business growth. Conversely, for established manufacturing firms, advanced packaging systems are available that can efficiently manage large-scale operations, ensuring consistent and swift production continuity.