What Are Food Packaging Machines?

Food packaging machines are industrial systems that are used to cover food substances using protective materials in order to distribute, store, sell, and consume them. They are more than just fillers of containers; they constitute a section of the production line that has been designed to execute particular tasks like forming, filling, sealing, wrapping, and labeling in a precise and efficient way. This equipment has the main goals of providing product safety, shelf extension, quality maintenance, and automation of time-consuming processes. The guide is systematic in offering an overview of the available technologies as well as the critical factors that producers need to put into consideration to make an informed investment.

Why Invest in a Food Packaging Machine?

Purchasing a food packaging machine will have more benefits than efficiency alone. The main business advantages of automation are the improvement of brand image, cost reduction in the operation, improved adherence to the food safety standards, and production scale. This is a summary of the value of automated food packaging machines as a core business of small business systems:

- Enhancing Brand Image

Food packaging is very important for brand image. Automated packaging allows consistency to be maintained and eliminates the human factor, and contributes to creating the professional and reliable image of a brand. The uniformity of packaging is not only guaranteed to increase consumer confidence but also has a positive impact on increasing the competitiveness of the brand within the market.

- Reducing Long-Term Operational Costs

Automated packaging machinery aids in balancing the cost of labor and the wastage of materials. With automation, according to the A3 Association, labor costs can be reduced by as much as 25%. Moreover, automated machines also save production costs by 20-30% as the wastes of materials are minimized.

- Ensuring Food Safety Compliance

The automated packaging process assists in maintaining food safety standards, since there is less potential for contamination and human error. The FDA asserts that automation minimises the likelihood of packaging-based food recall by up to 40 percent of the recall cases, thus preventing the economic loss and brand defamation.

- Achieving Scalable Production

The use of automated packaging systems increases production flexibility and efficiency and enables a business to respond better to the varying needs of the market. Automation enables companies to assemble their production facilities at a very high level to meet peak production or bulk orders and still ensure the product quality and efficiency of production remain constant.

Food Packaging Machine Quick Reference Chart

This chart will give a brief rundown of the critical performance pointers of each of the fundamental machine types, such as typical packaging speeds, normal price ranges, the main applications, and defining key features. You can use this table to draw up an initial shortlist of machine types that best suit your production output and budget needs to provide a clear foundation on which to base your supplier research.

| Packaging Machine | Packaging Speed (per minute) | Price Range (USD) | Applications | Key Features |

| VFFS (Vertical Form Fill Seal) | 60-150 bags | 50,000 – 200,000 | Snack foods, coffee, spices, powders | Efficient for high-speed, large-scale production |

| HFFS (Horizontal Form Fill Seal) | 50-100 items | 50,000 – 150,000 | Candy, cookies, and pharmaceuticals | Flexibility for varying shapes and sizes |

| Premade Pouch Filling & Sealing | 20-50 pouches | 40,000 – 120,000 | Nuts, granola, high-end snacks | High-quality packaging with functionality |

| Shrink Packaging Machine | 150-200 items | 30,000 – 80,000 | Meats, cheese, multi-pack products | High sealing protection, suitable for multi-pack |

| Gravity Filling Machine | 50-200 bottles | 40,000 – 120,000 | Liquids like water, juices | High-precision filling for liquid products |

| Piston Filling Machine | 30-100 bottles | 60,000 – 200,000 | Viscous products like sauces, creams | Precise volumetric filling for viscous products |

| Auger Filling Machine | 50-150 bottles | 80,000 – 250,000 | Powders and granules | Effective for powder and granule handling |

| Can Filling Machine | 50-150 cans | 70,000 – 150,000 | Canned soups, vegetables, and fruits | Handles high-temperature filling for preservation |

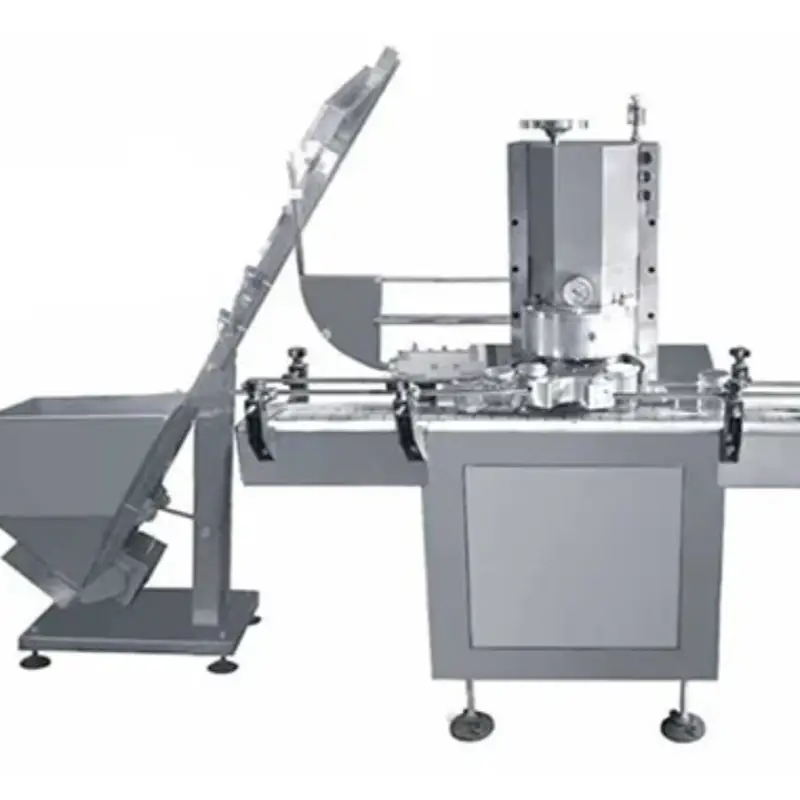

| Can Seaming Machine | 50-150 cans | 50,000 – 120,000 | Canned foods, beverages | Ensures airtight seals, tamper-evident |

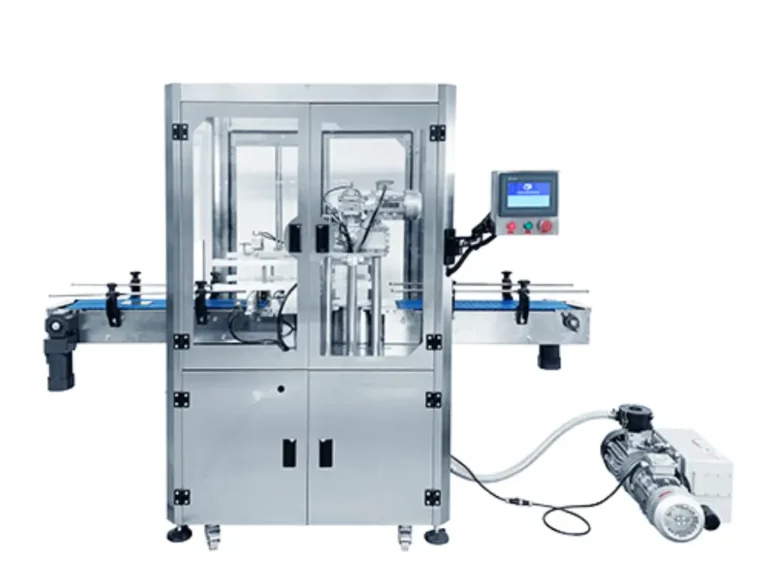

| Induction Sealing Machine | 100-300 cans | 30,000 – 100,000 | Tamper-evident seals for bottles/cans | Freshness and shelf-life extension |

| Tray Sealing Machine | 50-100 trays | 40,000 – 100,000 | Ready-to-eat meals, salads, and fresh meat | Suitable for high-volume, high-speed sealing |

| Cup Sealing Machine | 50-150 cups | 40,000 – 100,000 | Single-serve dairy products, drinks, snacks | Ensures product freshness and accurate sealing |

| Cartoning Machine | 50-150 cartons | 50,000 – 150,000 | Bulk products for retail sale | Efficient secondary packaging for retail |

| Case Packing Machine | 50-100 cases | 60,000 – 150,000 | Bulk products for shipping and distribution | Automatic case loading and packing |

Note: The price given is an industry estimate on standard models. Prices will differ widely depending on the manufacturer and the nature of the configurations, as well as customization required.

A Deep Dive into Core Food Packaging Machines & Systems

When selecting food packaging machines to be used by small firms, it is important to consider the safety of the product, shelf life, and the ability of the packaging machines to deliver the same brand to the consumer. Available equipment on the market varies extensively and is designed to handle certain food product types, materials, and container formats. In order to make a sound investment, it is necessary to have information about the core machinery types within the food packaging industry.

Bagging & Pouching Machines: Flexible Packaging Solutions

Flexible packaging is a major force in the food market, as it is more economical in materials and versatile as well as being lightweight. The main automated systems of the given category differ in the manner of the package formation and filling.

- Vertical Form Fill Seal (VFFS) Machines

A VFFS machine forms packaging out of a flat piece of film into a vertical tube. The system fills the tube with product above it, then creates the top and bottom seals to result in a finished bag. This vertical version provides a small footprint and is especially efficient with granular, powdered, or loose products such as snacks, coffee, and spices. It is highly used in continuous production because the typical speed of FFS machines ranges between 60-150 bags per minute.

- Horizontal Form Fill Seal (HFFS) Machines

A horizontal form, fill, and seal machine (or flow wrapper) works on a level surface and is used to wrap single solid products that run on a conveyor. It puts a film coating on the product, forming a longitudinal fin seal and two end seals. The standard of this type of packaging is the individually cut bars of candy, cookies, and baked goods. HFFS machines have a speed of 50-100 units per minute.

- Premade Pouch Filling & Sealing Machines

Unlike form-fill-seal systems, these machines do not start with bags or pouches that are made. It is in the process of automating the process of selecting, opening, filling, and sealing each pouch. Although slower-running at 20-50 pouches per minute, they are popular in applications where high-quality and retail-ready packages, like a stand-up pouch with a zipper, such as a premium nut, granola, or ready-to-eat meal, are desired.

Bottling & Jarring Lines: For Rigid Containers

Rigid containers such as bottles and cans will have filling, sealing, and labeling processes on the production line. Such systems play an important role in liquids, solids, and semi-solid products.

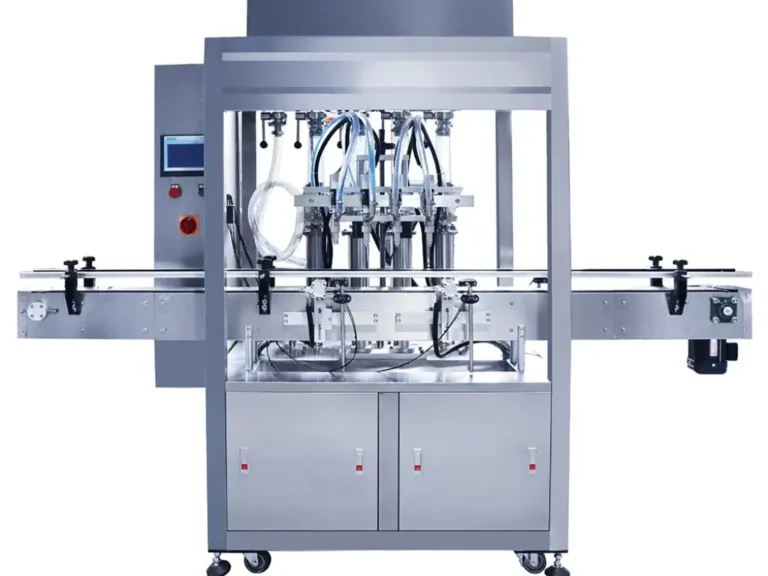

- Filling Machines

The filler is the core of any bottling line. Depending on product properties, the technology is selected: the gravity fillers are applied to thin and free-flowing liquids, piston fillers ensure more accurate volumetric fills of viscous products (sauces, creams, etc.), and auger fillers are used to fill powders and granules. Filling machines have a speed range of 50 to over 500 bottles per minute, depending on the product and required accuracy.

- Capping & Sealing Machines

Containers are sealed after filling. Typical types of cappers are chuck and spindle cappers to be used with screw-on caps. To seal it in place and provide tamper evidence, as well as a longer shelf life, an induction sealing machine is typically added. The system employs the use of an electromagnetic field to seal a foil liner to the rim of the container hermetically. Sealing machines have a capacity of 100-300 units per minute and guarantee airtight sealing for product preservation.

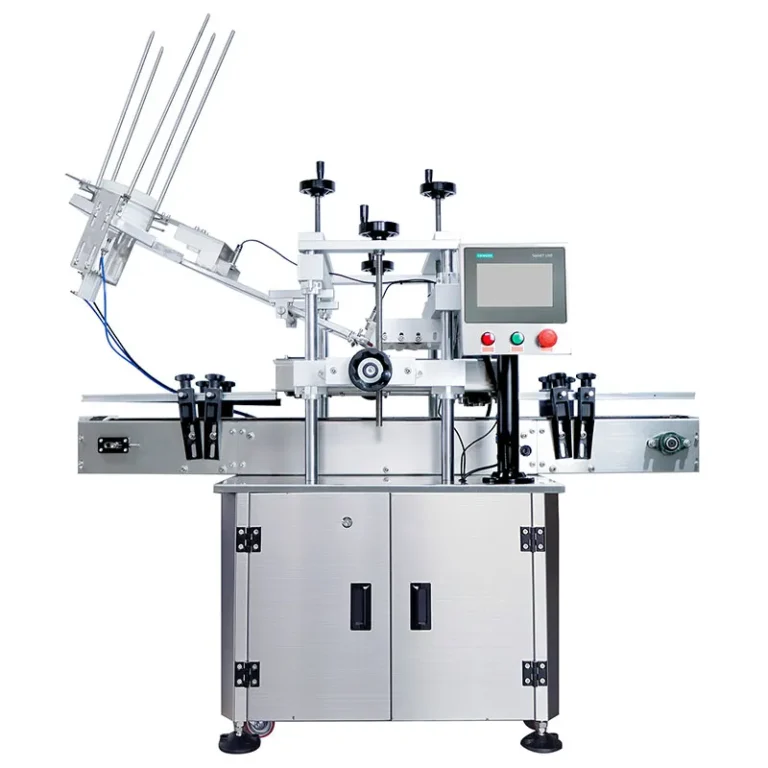

- Labeling Machines (Labelers)

The last stage of brand identity, as well as regulatory compliance, is labeling. Many container shapes can be labeled with pressure-sensitive labelers, but shrink sleeve and hot-melt glue labelers are typical high-speed full-body applications. Labelers today can run at rates of more than 500 bottles per minute.

Canning Systems: High-Temperature Long-Term Preservation

Canning involves a normal process of food preservation, especially where there a soups, vegetables, fruits, and sauces involved. Canning systems imply high temperatures and speed to guarantee the durability and the safety of products.

- Can Filling Machines fill cans with liquids, solids, or semi-solids, using machines such as volumetric piston fillers or pocket fillers. These systems run at speeds of 50–150 cans per minute and are designed to handle high-temperature filling processes to aid in sterilization and preservation. Canning is commonly used for long shelf-life products.

- Can Seaming Machines (Seamers) seal the can by interlocking the lid and the body of the can in a multi-stage process to produce a double seam. This makes the can and its contents in it safe. Seaming machines have a working speed of 50-150 cans per minute and are particularly important in terms of the shelf life of canned foods.

Tray & Cup Sealing Machines: For Fresh & Ready Meals

Tray and cup sealing machines are used in packaging ready-to-eat foods, fresh meat, salads, and dairy products such as yogurts. Such machines tend to use Modified Atmosphere Packaging (MAP) and Vacuum Skin Packaging (VSP) to preserve the shelf life of fresh goods.

- Tray Sealing Machines: These are the types of machines that seal the trays that are already pre-formed by the use of a flexible film lid. Most include Modified Atmosphere Packaging (MAP), where the air is replaced with a bespoke mixture of gases to retard microbial growth and prolong shelf life. Tray sealers are usually operated at a rate of 50-100 trays/minute.

- Cup Sealing Machines: Cup sealers work on the same concept as tray sealers, but are more suitable for pre-formed cups and ideal for single-serve dairy products, yogurts, and beverages. They tend to run at a rate of 50-150 cups a minute.

Shrink Wrapping & Bundling Systems

Shrink wrapping machines cover a product or a combination of products in a film of polymer. When the item is heated using a heat tunnel, it shrinks around the item. The technology is also commonly employed in multi-packs (bundling), tamper evidence, and environmental effects. The speed of production by shrink wrapping lines may vary up to 150-200 units per minute, depending on the purpose.

Cartoning & Case Packing: For Secondary Packaging

Secondary packaging is the packaging together of primary packages to be offered at retail or shipped. Cartoning machines and case packers are used to automatically erect cartons, insert primary packaged products, and seal the carton. Case packers are able to take a step further and place finished products into corrugated shipping cases, which are later closed, ready to be distributed.

- Cartoning Machines can automatically form and seal carton paperboard. They are used to make 50-150 cartons per minute and are used in high-volume packaging applications.

- Case Packing Machines automatically pack several finished products into large shipping cases. These machines can process 50-100 cases/minute, allowing high efficiency and saving costs on the labor force in the packaging business.

The food packaging machinery market is huge, and every system and equipment type has its characteristic to be fulfilled by the packaging equipment. When it comes to flexible bags, rigid containers, and even complex tray and cup sealing systems, the capabilities and areas of application of each machine are of the essence. With the right packaging equipment, companies are able to streamline their production, improve the quality of their products, and cut their production costs.

Key Factors to Consider Before Buying

An effective machinery purchase is not just about getting the machine to fit the product. The following operational and technical considerations need to be evaluated in detail.

- Production Speed: It is determined by the number of packs per minute (PPM) or bags per minute (BPM). This should be in line with your present and future needs for output.

- Machine Footprint: Assess the floor area that the machine will occupy and any clearance that it will need to operate, service, and be accessible to operators in your facility.

- Material Compatibility: Your selected type, thickness, and sealant properties of the packaging material must be compatible with the machine. This is more so in the move towards sustainable films and recyclable films.

- Changeover Flexibility: Evaluate the time and difficulty of changeover between various types of products or the size of packages. The main aim is to minimize downtime during changeovers to maintain efficiency.

- Sanitation and Washdown: Washdown and ease of cleaning of food applications, so that during food applications, you can easily clean the machine. Search stainless steel work (e.g., 304 or 316 grade) and IP ratings appropriate to your cleaning procedures.

Calculating the True ROI of Your Packaging Machine Investment

There are more benefits to investment in packaging machines than direct cost savings. They can raise the efficiency of production and the quality of products greatly. In order to determine the actual Return on Investment (ROI), it is important to evaluate the initial expenditure and long-term advantages, which include cost savings, high productivity, and consistency of the product.

1. Initial Investment and Costs: These are the costs of buying the machine, the cost of installing, training, and the maintenance costs. The high initial cost is compensated by the efficiency and productivity benefits the machine will bring later on, as it will save labor costs, production speed, and errors.

2. Labor Savings and Efficiency Gains: Automating packaging processes saves on labor costs in addition to efficiency. Moreover, the packaging machines stack products onto pallets, enhancing the speed of production and minimizing downtime, which leads to the overall performance and productivity.

3. Material Waste and Error Reduction: Since they enhance precision in packaging, packaging machines can reduce material wastage, as there would be fewer errors in packaging the products. It results in reducing the raw material costs and the returns of the packaging defects or reworks.

4. Improved Product Quality and Consistency: Automatic machines offer the same quality of packaging, thus enhancing the product quality and satisfaction of the customers. A decrease in errors and an increase in consistency will result in fewer product defects and complaints, which will ultimately increase brand reputation.

5. Long-term Savings and Total Cost of Ownership (TCO): Packaging machines have been made energy efficient, and this aspect reduces operational expenses in the long run. Also, they have a higher efficiency, which results in less maintenance and breakdowns, which decreases the Total Cost of Ownership (TCO). This is a good investment even though it might cost more at the front end, since there are savings in the long run.

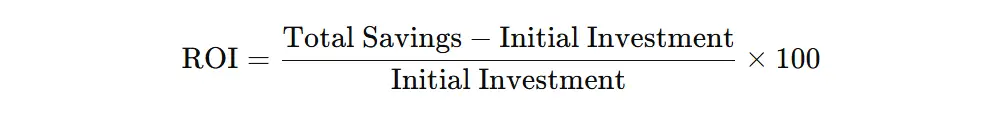

6. Calculating ROI: The important thing in computing ROI is to measure the cost savings against the cost of the initial investment. ROI calculation formula is:

This formula assists in determining the percentage of the money you will get back on your investment, calculating the payback period, and get to know the long-term advantages.

How to Choose a Reliable Machinery Supplier

The quality and support of your supplier are directly related to the long-term performance of your packaging machine. Screening must be strict.

- Technical Expertise & Documentation: The supplier must be well-versed and present with a very good knowledge of your application and possess the ability to provide extensive technical manuals, schematics, and documentation.

- After-Sales Support: Ask about how the service department is organized. What are their technical customer service response times? Is remote support provided?

- Parts Availability: Ensure that the supplier has a healthy stock of spares to reduce any downtime that may arise. Inquire about the lead time of critical parts.

- Customer References: Request to speak with current customers who have similar applications. This provides direct insight into the machine’s real-world performance and the supplier’s reliability.

- Factory Acceptance Test (FAT): A good supplier will permit you to test the machine using your products and materials at their plant before the machine is shipped.

10 Critical Questions to Ask Any Food Packaging Machine Supplier

As soon as you initiate the negotiations with the potential suppliers, a list of planned queries will help you obtain all the required data to draw a comparative picture.

- How many days are the critical spare parts available, and how much is the typical lead time?

- What is your technical support, and how much will it cost once the warranty expires?

- Do you have customer references for similar products and applications?

- What machine training do we get with the purchase of the machine for our operators and maintenance staff?

- What are the power and compressed air requirements of this machine?

- Is the Human-Machine Interface (HMI) user-friendly, and do we have the ability to save recipes of various products?

- How will it be done, and what will it cost to customize the machine to our specific needs?

- Will our actual product and packaging materials be tested by the machine before shipment?

- How long is the warranty, and what is covered?

- How is the software on the machine updated, and are there any related licensing costs?

LevaPack: A Leader in Food Packaging Solutions

LevaPack is a company that specializes in the automation of the food packaging industry globally. Having been established in 2008, we have gained profound experience in the field of canning, filling, sealing, labeling, and packaging machinery, and our products have been sold in more than 100 countries and regions around the world, and have won the affirmation of our clients in all parts of the world.

As a food production company, packaging machinery distributor, or OEM/ODM brand, LevaPack has tailor-made packaging solutions to suit your needs. Our equipment is of 304/316 food-grade stainless steel and equipped with key electrical parts of well-known international brands, which define the high efficiency, durability, and food safety standards.

Our OEM/ODM strengths enable us to provide customized designs according to customer needs, and we will assist you to streamline the production process, maximize efficiency, and guaranteeing product consistency. Select LevaPack to obtain high-quality equipment, professional technical assistance, and customizable delivery services, and be different in a competitive market.

Future Trends in Food Packaging Automation

The food packaging sector is developing day by day with the increasing needs of greater efficiency, sustainability, and data integration.

- Sustainability: Machines are being designed to run mono-material films, paper-based structures, and other recyclable materials that can be more difficult to run than traditional multi-layer plastics.

- Robotics and Integration: Robotic handling through pick and place, case packing, and palletizing is becoming core to end-of-line integration.

- Industry 4.0 (IoT): Smart machines that are fitted with sensors will be able to monitor their performance, predict when maintenance is required, and feed back real-time production data. This enables a better operational efficiency and less downtime.

- Improved Sanitation: Layouts that provide even easier access to clean and that minimize the possibility of contamination remain a priority, particularly in meat, dairy, and ready-to-eat.

Conclusion: Ready to Find Your Solution?

In a nutshell, choosing the appropriate food packaging machines for small businesses plays an important role in improving the efficiency of production, food safety, and the hygiene quality of products. By learning the types of packaging machines that are used in food and taking into consideration aspects such as speed of production, material compatibility, and the support offered by the suppliers, companies can make strategic decisions that make their operations streamlined. Automation can help to cut down labor, reduce waste reduction and increase scalability. Also, it is important to select a trustworthy supplier with a well-developed after-sales service and possibilities of customization to achieve long-term success. When a company has the appropriate machinery and supplier, it can raise its competitiveness in the market, serve the market needs, and build its brand image.