What Is Tuna Processing?

Tuna processing refers to the transformation process of raw tuna (usually caught with the use of purse seine fishing) into ready-to-eat products such as canned tuna or tuna pouches. This begins with the catch and delivery of the fish, usually frozen tuna, to a processing facility, in which it is rethawed, cleaned, cooked, packed, and sealed. Every single process is controlled to maintain the safety of food, its quality, and shelf life.

What is so important about this process? Since consumers demand safe, delicious, and shelf-stable products. It implies that all the stages of the canning procedure, i.e., the gills and excess oils removal, the moisture test, and the appropriate sterilization process, should be ruled by strict regulations. The trees also minimize solid waste through conversion of leftovers into fish meal, fish oil or pet food.

Properly done, canned tuna manufacturing produces quality products such as white albacore tuna in brine, oil, or sauces. Throughout the entire process, high-speed machines are used to pack them into cans or pouches; they are tested against such things as temperature, bacteria, and the strength of the seal.

Simply put, tuna processing processes tuna sea-to-shelf with a combination of technology, food safety regulations, and effective processes. It is not merely cooking but a sophisticated system that is aimed at ensuring that consumers market all over the world receive safe, consistent, and delicious seafood.

Step-by-Step Tuna Processing Techniques

The tuna processing is a carefully planned, systematic process aimed at producing a high-quality, shelf-stable product that is safe. Every process, which includes the reception of the raw tuna to the sterilization process, should be conducted carefully in order to comply with food safety standards as well as with the demands of the market.

Receiving and Thawing the Raw Tuna

The tuna processing cycle starts with reception of whole, usually frozen tuna that is received directly off fishing boats. During transportation, these fish are normally kept at temperatures of -18 ℃ or less to avoid spoilage and prevent the growth of bacteria. After unloading, we place the tuna in large stainless-steel thawing tanks that circulate water at a constant, gentle temperature. This slow, uniform thawing is essential; a quick or uneven thaw risks breaking down the fish’s cells, altering its texture, and losing nutrients. Proper thawing also allows us to grade the fish accurately and feed it smoothly into the next mechanical steps. Throughout the thawing, operators measure core temperatures continuously, watching for a final internal range of 0°C to 4°C that is safe and ready for processing.

Sizing and Sorting

Once the tuna is thawed, it is then put through the sizing and sorting process. In this case, the fish is graded into species, weight, and visible quality specifications via a blend of manual skill and automated conveyor-based grading. Machine vision systems or laser scanners can be used in high-capacity lines to identify parameters such as length, girth, and external defects. This is done to ensure the efficient assignment of fish to specific end products; larger, high-fat individuals are typically directed to canned loins, while smaller/darker-fleshed tuna can be directed into flaking or pouch products. Proper grading here is vital in maximizing the yield and maintaining the uniformity of the batches, more so when high-value differentiated products such as premium albacore tuna are produced.

If you would like to learn more about the different types of tuna, you can check out our article on the different types of canned tuna.

Pre-Cooking (Steaming or Boiling)

The pre-cooking is a basic process that aims to soften the tuna partly, ease the process of trimming, and lower the oiliness. Tuna can be cooked in steam cookers or in boiling vats, depending on the configuration of the plant and the intended product quality. High-grade products should be steamed as the process maintains meat integrity, moisture, and color. Although a little harsher, boiling can process more quickly, and is most commonly used in bulk. There is very rigid control of time and temperature, usually 85 °C to 100°C, 30 to 60 minutes, depending on the size and type of fish. Denaturation of proteins may result in overcooking, whereas undercooking may hinder subsequent sterilizing processes, hence constituting a critical control point (CCP) in the majority of HACCP schemes.

Cooling and Cleaning

After cooking, tuna must be chilled quickly to slow microbial growth and ready it for handling. Most plants use chilled-water sprays or immersion tanks. In this step, surface oils, blood residue, and denatured proteins are washed out. This step boosts hygiene and sets the texture for later operations. Temperature, flow rate, and soak times are tightly controlled to prevent uneven warming or recontamination. Effluent in such plants is treated and reused in most plants in management strategies for water sustainability.

Loins Separation and Deboning

After cooling, the tuna is then taken through trimming lines where either an experienced workforce or machines that are controlled by precision will cut the loins off the remaining body mass. This involves the removal of the bones, the skin, dark muscle, gills, and any parts that cannot be eaten. With higher-end production lines, the trimming is done nearly all by hand in order to maintain quality, whereas large-scale processors are becoming more and more dependent on semi-automated deboning machines. The loins are removed and reinspected, and graded. After which, they are cut to the desired lengths or flaked. By-products, such as bone and offcuts, are harvested to be used to make fishmeal, pet food ingredients, or oil, contributing to the waste reduction and by-product use objectives.

Filling and Canning

Once the loins have been trimmed and cut to specification, they are loaded into containers—either aluminum cans or high-barrier pouches—according to the product guidelines. High-speed filling machines carry out this operation, governed by strict tolerances that guarantee consistent weight and uniform compaction. Any deviation in fill weight risks noncompliance with labeling regulations and can lead to consumer complaints. Tuna layout within the container (e.g., layered, chun,k or flaked) is also important to the visual appeal and brand consistency. For top-tier offerings, hand-filling may be employed to maintain the loins’ delicate structure and achieve the desired visual finish.

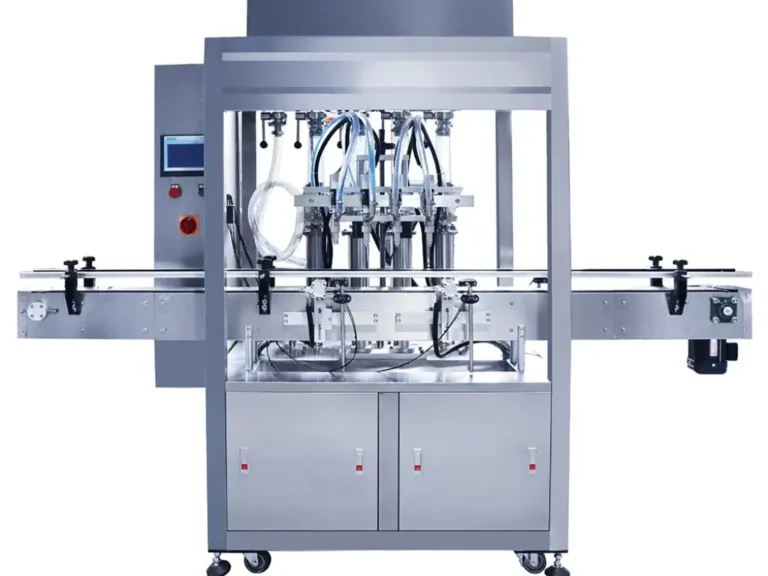

Liquid Addition (Oil, Brine, or Sauces)

After filling, a measured amount of liquid preservative is introduced into each jar. The choice of liquid—vegetable oil, salt brine, or a seasoned sauce aligns with market demands and product goals. Oil enhances flavor and smoothens texture, a benefit for fattier types like yellowfin or skipjack. Salt brine, favored for lighter tuna lines, caters to health-aware shoppers. Automated liquid dispensers deliver the exact volume, cutting the chances of overflow and leak at the lid. Excess liquid weakens the vacuum seal, while a shortage risks dryness once sterilization is complete. Liquid fill levels are typically monitored by level sensors and weight verification systems.

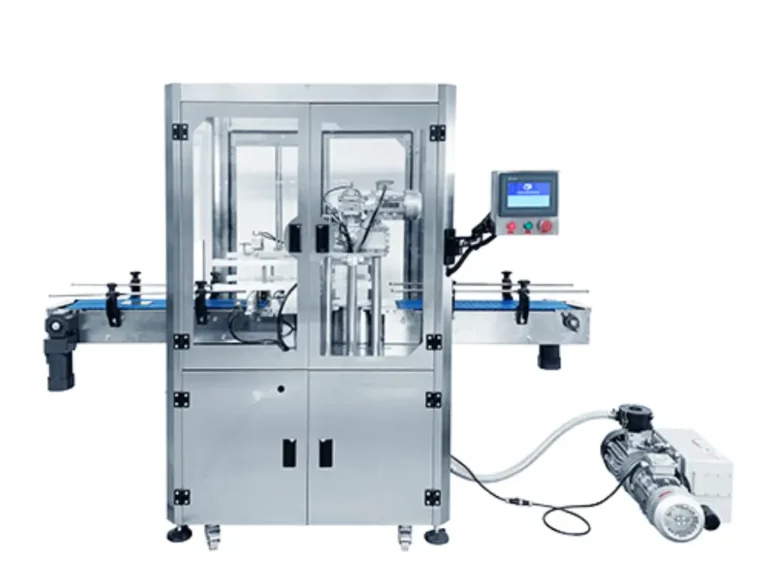

Sealing and Vacuuming

Right after filling, containers travel to the sealing zone. Cans are closed by high-speed seamers, and pouches go through vacuum sealing followed by heat. The aim is a complete hermetic seal that stops oxygen from entering, thus avoiding microbial growth and oxidation. Today’s seamers have digital inspection that monitors seam integrity on the spot, ejecting any can that doesn’t meet the narrow tolerance. Vacuum levels are set to drop residual oxygen and set the stage for uniform thermal sterilization. Even a small variation in seam width, overlap, or thickness is treated as a critical quality failure, leading to immediate product segregation.

Retort Sterilization (High-Pressure Cooking)

Sterilization is the most decisive moment in tuna canning. Manufacturers choose between batch retorts and continuous rotary systems, placing sealed cans in an environment where the temperature exceeds 121°C and the pressure rises above 15 PSI. The duration of treatment is customized according to the can size and type, directed at eradicating Clostridium botulinum along with other resilient pathogens while retaining flavor and texture. Internal can temperatures are logged by thermocouples or portable data loggers, and every variable—from time and temperature to pressure—is recorded, satisfying both regulatory standards and internal audits. Any deviation from the validated cycle can lead to entire batches being thrown out or expensive recalls, compelling the industry to enforce meticulous controls and constant surveillance.

Labeling, Packaging, and Dispatch

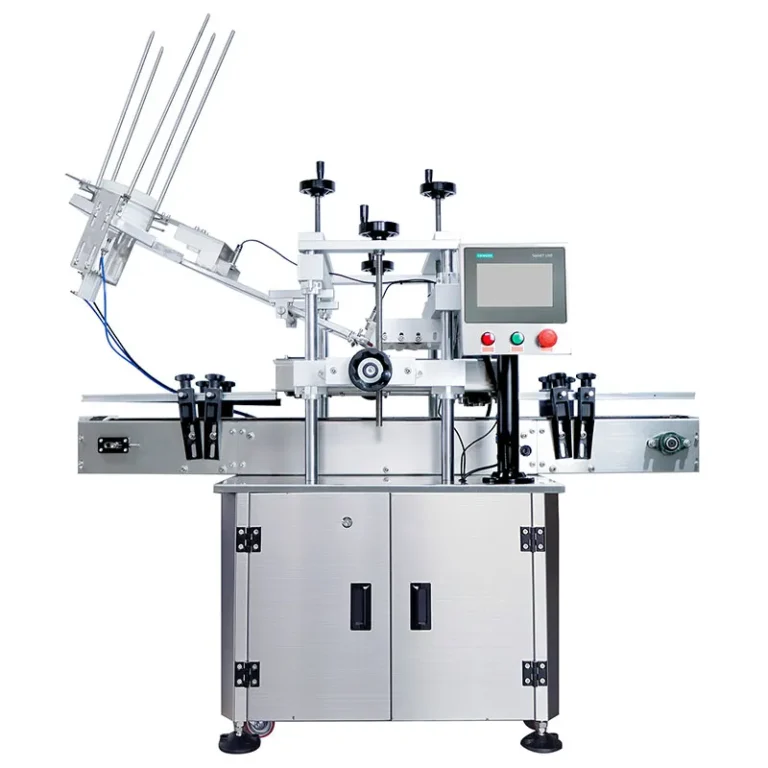

Cans are dried and channeled to labeling lines after cooling. In this case, batch codes are encoded in inkjet, and printed labels are applied automatically. Some facilities incorporate digital traceability services, including blockchain-enabled QR codes, which enable the end-users to trace the tuna to the vessel and location where the tuna was caught. Secondary packaging- cartons or shrink-wrapped trays- are used to group labeled products; then they are stored or shipped on a pallet. Warehouse tracking is usually done by barcoding of pallets. The ultimate check is done upon dispatch so that all regulatory, labeling, and customer-related requirements will be satisfied, and a full-cycle production process with a focus on safety will be completed.

Key Equipment Used in Tuna Processing Plants

Tuna processing involves large-scale machinery and equipment specifications, and to processing large quantities of fish quickly, safely, and with uniformity. Production of canned tuna in large quantities would not be possible without the right machines.

- Pre-Cookers and Steam Chambers

Tuna is cooked before being cleaned by the use of boiling or steaming by pre-cookers. The machines work with loads of several tons at once and have accurate temperature and steam regulation to keep the texture and flavor of the fish. The white albacore tuna goes well in steam chambers, and this preserves the light color of the fish. A lot of units are equipped with a steam recycling system to be economical with energy and water.

- Automatic Loins Separator and Trimming Tables

Cooking and cooling then lead to the tuna transferred to trimming tables, where the bones, gills, and skin are removed. This can either be a manual or semi-automatic process. The leftover is thus gathered and utilized as fish meal, fish oil, or even pet food, decreasing solid waste.

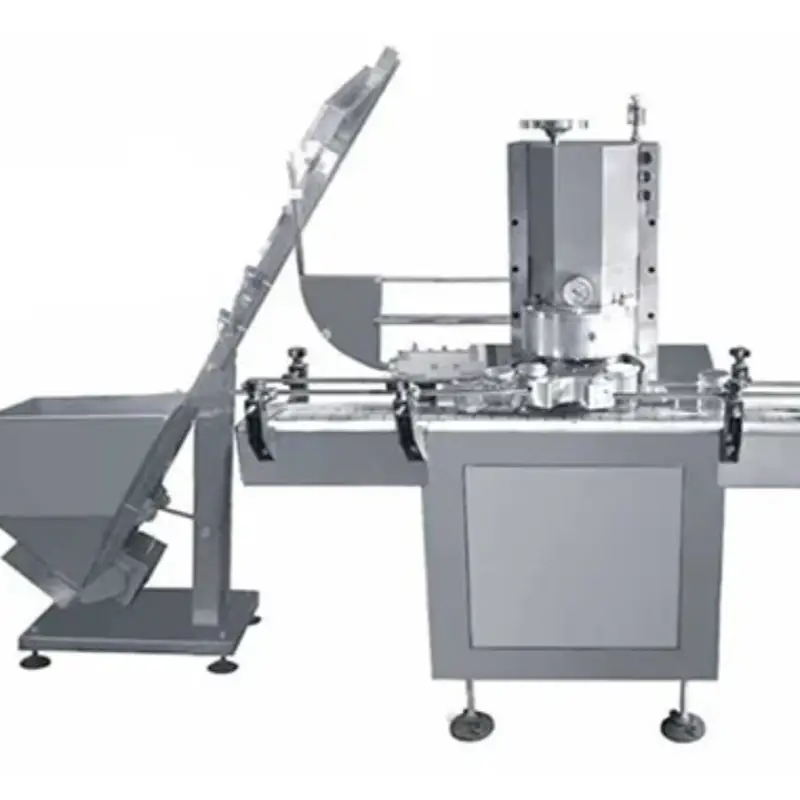

- Filling Machines and Can Seamers

Then, tuna is packed in cans or pouches using filling machines, and portions are weighed in order to be consistent. Brine, oil, or marinade is also added to the machines. Then, it is possible to seal the cans tightly under vacuum by seamers, which is important in the following process, retort sterilization.

- Retort Sterilizers (Batch and Continuous)

These are pressure cookers where sealed cans are sterilised at temperatures of more than 115 °C. This makes the product shelf-stable and safe. They are in batch and continuous form, where all of them have real-time temperature and pressure tracking. This is the necessary step in achieving food safety regulations.

- Conveyors, Cooling Systems, and Labeling Lines

Cans that have been sterilized are then cooled down quickly with water tanks or air systems. They are transported on conveyors to labeling machines where product information and traceability information is applied. The last step entails the packing of the cans to be distributed.

Levapack: A Reliable Packaging Partner for Tuna Processing Excellence

In such a strict industry as tuna processing, precision packaging equipment is not an option but a necessity. That is where Levapack can be used as a reliable partner of both the large-scale processors and smaller food manufacturers. Levapack is a company that specializes in canning and sealing technology, but provides automated and semi-automated solutions to the food industry with solid, liquid, viscous, and powder filling systems that are compatible with tin cans, aluminum cans, plastic jars, etc.

Levapack was established in 2008, but has experience of more than 18 years in the design and manufacturing of packaging machinery. The company has a 4,000-square-foot production plant with CNC machining equipment and automated assembly lines to guarantee high-precision production and stable output. The equipment of Levapack has been supplied to its customers in more than 100 countries, and the main areas are North America, Europe, the Middle East, Southeast Asia, and South America.

In the case of tuna processors, Levapack offers the necessary features such as vacuum sealing, nitrogen flush, and tailored filling lines, which are important in maintaining freshness and shelf life. Its machines are constructed with 304/316 food-grade stainless steel and globally-reputable power parts (e.g. Siemens, Schneider, SMC). As an OEM customer, mid-sized factory, or as a packaging distributor, Levapack offers flexible, efficient, and scalable solutions in line with the current seafood production requirements.

Advanced Automation and Smart Technologies

The processing of tuna is no longer a manual process. Nowadays, the latest automation, AI, and real-time tracking are the keys to effective and secure manufacturing. Let us discuss the way technology is transforming canned tuna processing.

- Role of AI and Machine Vision in Quality Grading

Quality grading that was previously performed manually is now performed by AI and machine vision systems. The systems can check the color, fat distribution, and texture, particularly in the processing of white meat tuna like albacore. There is detection of even minor color changes or fat streaks, and this makes it consistent and less prone to human error.

It is also possible to identify defects like mini bones or wrong cuts using machine vision so that only the best loins end up in cans. With the addition of AI to the feedback loops that operate continuously, processing plants can automatically adjust machines, wasting less and attaining higher levels of efficiency.

- Energy-Efficient Processing Systems

A trend in tuna processing is energy efficiency. Such technologies as steam recovery systems and maximized freezers assist in cutting down energy use. Energy-efficient systems guarantee seamless production in places where electricity reliability is an issue, such as American Samoa, as well as reduce the costs of operation.

Such innovations not only turn the plant into a greener one but also increase profitability through decreased utility bills. Additional mitigation of sustainability in the industry is the use of inverter-driven motors and environmentally friendly refrigerants.

- Real-Time Monitoring and Data Logging Tools

The present-day tuna processing facilities are crammed with real-time monitoring. All aspects, such as moisture content in loins, sterilization temperatures are monitored and analyzed automatically. This will make sure that any deviation, like in temperature or pressure, is noticed and fixed.

These systems are essential to the adherence to food safety, such as HACCP and international food regulations. They also facilitate predictive maintenance, which notifies the operators of possible equipment failures before they interfere with production.

Quality Control in Tuna Processing

When processing canned tuna, quality control is not the last step but an integral part of each process. Frozen tuna is thoroughly inspected from the moment it arrives at the plant until the time it is packaged, ensuring that the product’s quality meets the highest standards.

- HACCP and Food Safety Standards

The international standard of seafood safety is HACCP (Hazard Analysis and Critical Control Points). In the processing of tuna, it is the identification of risks, including bacteria or physical contaminants, and the monitoring of critical steps of sterilization or sealing. Any slight change in the established parameters, including temperature or pressure, halts the production line to prevent contamination.

Audits by third parties are also usual to make sure that they are in line with the required compliance, such as the EU, the U.S., or Japan. Such food safety procedures are important since failure to pass these audits can bring down operations.

- Temperature, Microbial, and Metal Detection Checks

It is important to control the temperature. Frozen tuna storage, pre-cooking, and retort sterilization are some of the methods of ensuring that bacteria are at bay, with strict thermal monitoring. Pathogens such as Salmonella or Listeria are also tested on swabs and samples, and microbial testing is conducted regularly.

Besides, each can and pouch is scanned by metal detectors before it can be considered as a potential contaminant. Even small pieces of metal are also alerted, and the whole batch can be recalled in case of need.

- Sensory Testing (Texture, Flavor, Appearance)

Although the use of technology is very high, the role of sensory testing by human beings remains essential. There are trained testers who measure the texture, flavor, and appearance of the product to ensure that the product is of the expected standard. To illustrate, albacore must be light-colored, pinkish, and with a clean and smooth flavor. When the tuna is dry or discolored, that may be a sign of problems with processing.

- Traceability and Batch Documentation

Every tuna batch receives its particular batch number, and this number follows the fish through the fishing boat to canning production. With this traceability system, you can be sure that in the event of a problem, be it a contamination problem or a complaint by a customer, the root cause can be found out in a few seconds. Such a system would also ensure that the tuna is sourced under sustainable, ethical fisheries, and products are of global food safety standards.

Common Challenges in Tuna Processing — and How They’re Solved

Canned tuna processing has many challenges to handle, including the quality of the raw materials that are inconsistent, the large amount of energy used, food safety issues, and regulatory compliance, even in the most modernized plants. Such problems not only impact the efficiency of operations, but also brand image and market conformity. A list of common industry issues and their usual solutions to overcome them follows below:

| Challenge | Description | Typical Solution |

| Inconsistent Raw Tuna Quality | Variations in fish size, freshness, or fat content affect product uniformity. | Use AI-powered grading systems; enforce strict supplier quality controls. |

| High Energy Consumption | Pre-cookers, freezers, and sterilizers consume large amounts of power. | Introduce energy-efficient equipment, steam recovery systems, and staggered equipment scheduling. |

| Food Safety Risks | Bacterial or foreign object contamination poses serious health threats. | Implement HACCP, metal detection, microbial testing, and strict sterilization processes. |

| Equipment Downtime | Malfunctions can halt production and increase costs. | Adopt preventive maintenance programs; install real-time monitoring and predictive failure alerts. |

| Labor Shortages or High Turnover | Lack of skilled labor affects consistency and productivity. | Cross-train employees; invest in ergonomic workstations and partial automation. |

| Solid Waste Management | Waste like gills, heads, and offcuts can accumulate rapidly. | Repurpose byproducts into fish meal, fish oil, or pet food to minimize waste. |

| Export Compliance Requirements | Regulatory demands vary across export markets. | Establish compliance teams; use real-time documentation and undergo third-party audits. |

| Batch Consistency Issues | Variability in fill weights or seal quality can cause product recalls. | Employ high-precision fillers, automatic weight checks, and AI-based quality inspection. |

| Environmental Sustainability Pressures | Stakeholders expect greener, low-impact processing. | Adopt solar energy, water recycling, sustainable packaging, and certified sourcing from fisheries. |

| Traceability in Complex Supply Chains | Difficult to trace fish from catch to consumer. | Use end-to-end digital traceability systems integrated with ERP or blockchain platforms. |

Conclusion

Canned tuna production is not so straightforward as it appears; the process of manufacturing is a complicated mixture of biology, engineering, and cooking perfection. It is a long process, starting with fishing in the Pacific, up through high-tech processing, thawing, pre-cooking, and sterilization, but all of it has very specific criteria, quality control, and meticulous management. There is also efficiency in automation, AI, and real-time monitoring.

The main essence of canned tuna processing is that it is a balance between tradition and innovation, which is of high quality to satisfy the environmental and consumer requirements. Thus, the next time you open a can, think that it is the product of decades of accuracy and technological improvement.