Introduction

The international manufacturing environment is a dynamic marketplace that is continuously redefined by changing economic forces and technological changes. Over the past few years, production establishments in most sectors have been struggling with a combination of issues that jeopardize their existence in terms of operational integrity. Statistics provided by the World Economic Forum consistently attribute ongoing disruptions in supply chains, and the International Labour Organization is also constantly reporting on a growing skills gap and labor shortages affecting production capacities across the globe. At the same time, the necessity of sustainable practices, which is dictated by consumer demand as well as by regulatory forces, introduces an additional level of complexity. It is against this background that the ubiquitous problem of production problems emerges as a major obstacle to operational efficiency, product quality, and eventually profitability. The blog will explore the underlying cause of these complex issues, and in the context of the food packaging industry, where the risks of operational excellence are exceptionally high, impacting public health and brand image.

The Core Challenges of Modern Production: Beyond the Basics

The bigger economic and international events always influence the manufacturing operations, no matter how big or small they are. The problems you observe in the production are mostly symptoms of underlying, persistent problems that can have a significant impact on the operations. These are some of the main challenges that should be understood to have a strong and flexible operation program.

- Supply Chain Complexity

The international supply chain has turned extremely complex. The geopolitical changes, trade regulations, and the occurrence of some unforeseen circumstances, such as pandemics or natural disasters, may lead to high levels of delays, shortages in materials, and unstable changes in prices. Manufacturers have to wait longer to get the necessary raw materials, shipping becomes more expensive, and the risk of production stoppage increases. It is always difficult to control a wide range of suppliers located on different continents, which disturbs the production plans and leads to the necessity of fast changes, particularly without transparency of the whole production process.

- Labor Shortages and Skill Gaps

The issue of locating and retaining skilled laborers has become a huge concern for manufacturers across the world. Shortages have resulted due to population changes and the absence of vocational training. This touches on the daily operations, servicing of the complex equipment, and embracing new technologies. This is aggravated by an aging workforce in most developed countries. These are some of the most common issues that manufacturers should surmount to achieve high quality output.

- Rising Energy Costs

Industrial production is dependent on energy, and it provides energy to large machines as well as climate control systems. Fluctuations in international energy markets, which are usually occasioned by political instability or changes in supply and demand, have a direct effect of increasing operating costs. Manufacturers will be faced with erratic utility bills that may cut down profits and compel them to make hard choices regarding pricing or output.

- Demand for Sustainable Production

The thing is that sustainability is not optional anymore. Customers and regulators are pressing to keep environmental impact as low as possible as well, increasing the pressure to minimize waste, emissions, and enhance energy usage. It usually needs new technologies, new quality standards, and new approaches to running operations.

Common Production Issues Plaguing Food Packaging Operations

The food packaging industry has a stable consumer base, but it is particularly subject to unique and exaggerated production issues. Large production, stringent safety regulations, and perishable goods all contribute to high levels of inefficiencies and quality issues.

Efficiency, Downtime, and Throughput Bottlenecks

One of the problems is a constant inefficiency. The overall equipment effectiveness (OEE) of packaging lines is usually low because of frequent machine failures, time-consuming changeovers between products, and unbalanced lines. One bottleneck machine may limit the whole production process, which will cause low productivity and failure to meet deadlines. This has a direct effect on the capacity of a manufacturer to address the demand in the market, and it may lead to huge losses.

Product Loss and Waste

Food products tend to go bad. In packaging, this implies a significant amount of product loss due to improper filling, package failure, such as poor seals or holes in the packaging, or improper labeling. Each kilogram of product lost because of packaging defects not only costs material but also wastes energy and labor, as well as disposal costs. For example, inaccurate fillers may result in expensive overfills, an ineffective sealing mechanism may destroy a whole batch of perishable goods, and valuable inventory may be converted into industrial waste.

Quality Control Deficiencies

It is also important to sustain the quality in food packaging processes as it has a direct impact on food safety and brand image. The typical quality issues can be classified as uneven seal strength that results in leaks and contamination, incorrect labeling that may pose risks of allergies, and the presence of foreign objects in packages. Uncontrolled, these problems may lead to product recalls, regulatory penalties, and the dire loss of consumer confidence, which is a brand’s most treasured asset. The problem here is that it is difficult to set strong points and systems of inspection that will be able to notice small defects at a high production rate due to a lack of transparency in the inspection processes.

Regulatory and Compliance Pressures

The food industry is governed by a rigid set of local and international regulations on matters of hygiene, materials, labeling, and traceability. Non-compliance has dire consequences, limited market access, and reputation loss. It is necessary to monitor changes in the standards of such bodies as the FDA or EFSA to stay in the game and have flexible production procedures. Additional complexity is created by the necessity to document and validate the daily processes.

Labor Dependency and Automation Gaps

Even with the technological advancements, numerous food packaging activities continue to be highly manual in loading, inspection, and case packing. This dependency brings in the factors of human error, fatigue, and speed constraints of manual operation, which directly affect consistency and throughput. In a time of increasing labor prices and scarcity, a lack of automation is a weakness.

Flexibility and Customization Demands

The tendency of the market to a varied range of products, reduced batch sizes, and individual packaging requires very flexible production lines. The conventional, inflexible packaging equipment is not able to respond swiftly to repetitive changeovers of products, resulting in long downtimes and low productivity. The capacity to easily change package size, material, and product type without a lot of retooling is a vital issue for most manufacturers.

It is good to have a brief outline of the biggest problems and how best manufacturers are addressing them through a roadmap before going into details of the technologies:

| Category | Common Issues | Recommended Solutions |

| Equipment Efficiency | Frequent downtime, long changeover times | Automation, SMED techniques, OEE monitoring |

| Product Waste | Overfilling, sealing failures, and spillage | Precision filling, vision inspection, and weight control |

| Quality Assurance | Seal leaks, foreign objects, and mislabeling | AI-driven inspection, traceability systems |

| Labor Dependence | Manual handling errors, low throughput | Robotic case packing, collaborative robots (cobots) |

| Flexibility Limitations | Difficult SKU changeovers, low customization | Modular lines, digital recipe management |

Leveraging Advanced Technology for Seamless Packaging Production

The numerous issues in the production of food packaging can only be resolved through the active implementation of high-tech solutions. Such innovations are not minor; they are a radical shift in the way production lines work and can be characterized by unrivaled precision, efficiency, and flexibility.

Automation and Robotics

Probably the largest technological change is the use of automation and robotics. Robotic arms are capable of doing repetitive and high-speed activities such as picking, placing, packing, and palletizing with high accuracy, much more than human beings can do in the long run. This not only enhances production by a big margin but also eliminates the risk of human error and manpower shortage. Automated guided vehicles (AGVs) can transport materials in the factory efficiently to enhance internal logistics and reduce bottlenecks.

Smart Sensors and Machine Vision

A modern packaging line is essential to have smart sensors and machine vision systems. With high-resolution cameras and powerful software, even the smallest imperfections in packaging materials can be identified, labels correctly positioned, seals checked, and foreign bodies identified, all at rates that the human eye could never manage. These systems offer immediate feedback, and this makes it possible to make corrections immediately. This greatly minimises the wastage and also ensures the same quality of products before the items get off the factory floor.

Internet of Things (IoT) Data Collection and Analytics

The IoT sensors installed in packaging equipment gather significant data about the performance of the operations, such as temperature, pressure, speed, visibility, vibration, and energy consumption. When this raw data is fed into high-end analytical platforms, it becomes valuable insights. Manufacturers can observe equipment performance in real-time, track trends, determine inefficiencies, and identify any potential problems leading to downtime. This data-driven approach allows for continuous improvement in processes.

Predictive Maintenance

Instead of making repairs after something has broken, predictive maintenance employs IoT data and analytical models to predict when equipment is likely to fail and make repairs before the equipment fails. These systems are able to forecast when a certain component may fail by continually checking the health of the machine (e.g., vibrations, temperatures). This initiates an active maintenance plan that reduces unplanned shutdowns, increases the life of equipment, and maximizes maintenance expenses, resulting in a fluent and reliable production process.

Artificial Intelligence (AI) in Production Optimization

AI goes one step further in the data analysis, allowing intelligent decision-making. The AI algorithms can optimize the production schedules and control inventory levels, helping to address the most common problems faced in production. Moreover, they can even modify machine settings on a real-time basis due to a fluctuating demand or material availability. In quality control, AI systems are learning to detect complex defect patterns that other vision systems would not detect, eventually leading to increased customer satisfaction. Such a degree of optimization contributes to more agile and responsive production lines to changes in the market.

Strategic Approaches to Optimize Packaging Line Efficiency

Efficiency in packaging lines does not only entail the application of high-tech technology. It also demands intelligent management and operational adjustments. Technology drives the line, but good processes and competent people steer it.

- Lean Manufacturing Principles

Lean can be used to bring about a very positive change to a packaging line. The methods, such as Single-Minute Exchange of Dies (SMED), help shorten the time between the changeovers of different products, keeping the stoppages minimal. 5S methodology is used to sort the workplace in a more efficient and safer manner. Such principles assist in defining waste and removing it, thus optimizing the whole process of packaging.

- Advanced Planning and Scheduling (APS)

Production planning is crucial. APS systems are based on algorithms to optimize schedules, taking into account the machine capacity, materials, labor, and demand. This results in practical plans, reduced bottlenecks, less idle time, and better on-time delivery.

- Just-In-Time (JIT) Inventory Strategies

The JIT principles reduce inventories by making sure that materials are brought in and goods produced only when required. This saves a lot in storage expenses, wastage, and release of capital. It needs tight coordination of suppliers and good production.

- Employee Training and Skill Enhancement

Experienced operators are necessary even with sophisticated machines. Detailed training on new equipment, problem-solving, and Lean is important. Allowing employees to propose improvement solutions will lead to ongoing efficiency.

- Human-Machine Collaboration

The packaging production of the future means continuous collaboration of man and machine. Collaborative robots (cobots) are robots that collaborate with human operators and help with mundane or labor-intensive tasks. This collaboration brings the precision of machines and the flexibility of a human to the environment, which becomes more dynamic.

Ensuring Food Safety & Quality Through Packaging Excellence

In food products, safety and quality are mainly safeguarded by food packaging. It increases the shelf life, it protects against contamination, and it carries important information. The presence of any packaging failure has a devastating effect on the health of the consumer and the brand name.

- Aseptic Filling and Sealing Technologies

Perishable foods should be packaged in a sterile manner. The aseptic filling systems work under sterile conditions, and they are not contaminated. The high-level sealing forms airtight (hermetic) seals that preserve products fresh longer without refrigeration.

- Design for Contamination Prevention

The design of machinery is the most important tool to avoid contamination. Equipment should be smooth with no crevices, with food-grade materials easy to clean. Such features as quick-release parts, closed systems, and zoned areas reduce the risks of cross-contamination.

- Packaging Integrity Detection and Traceability Systems

Packaging integrity is essential to be verified through an automated inspection. Vision inspection to detect seal defects, pressure decay tests to detect leaks, and X-ray inspection to detect foreign objects are technologies that are used to detect bad packages in a short time. Effective traceability (barcode or RFID) is used to track all packages, so it is easy to determine which batches are involved in a recall.

- Adherence to Food-Grade Materials and Hygiene Standards

The selection of the materials is highly regulated to exclude the possibility of leaching of harmful substances into food. The food industry manufacturers are required to employ certified food-grade products and have high standards of hygiene. This entails frequent sanitization and Good Manufacturing Practices (GMP) and Hazard Analysis and Critical Control Points (HACCP).

- Environmental Control

In certain food items, certain environmental conditions in the package are critical. This includes vacuum sealing (Oxygen removal), gas flushing (inert gases such as nitrogen), or modified atmosphere packaging (MAP). These preservatives maintain the flavor, texture, and nutritive value and increase shelf life.

The Levapack Advantage: Precision Engineered for Your Success

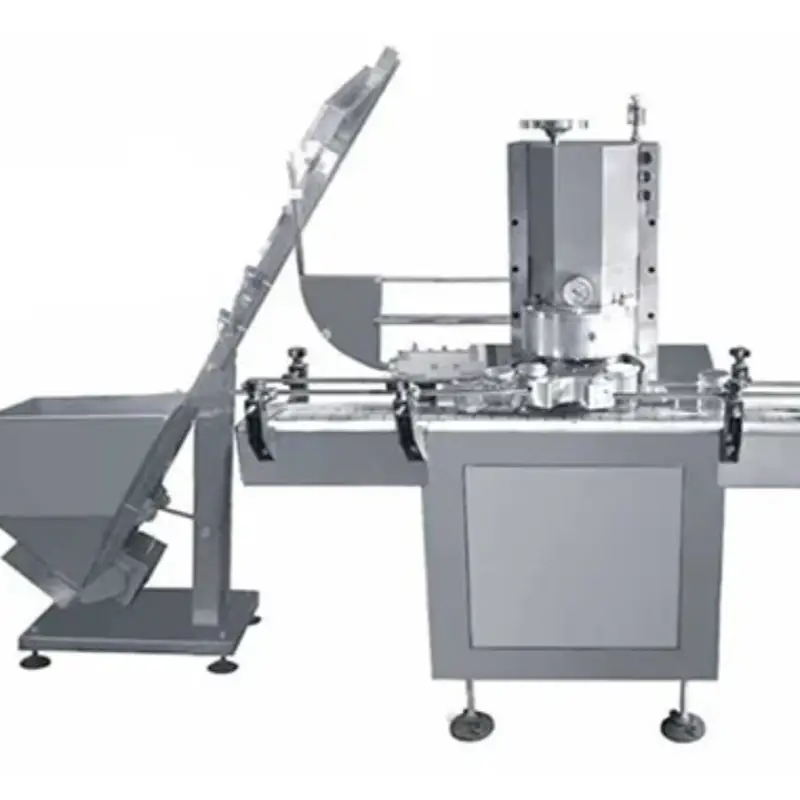

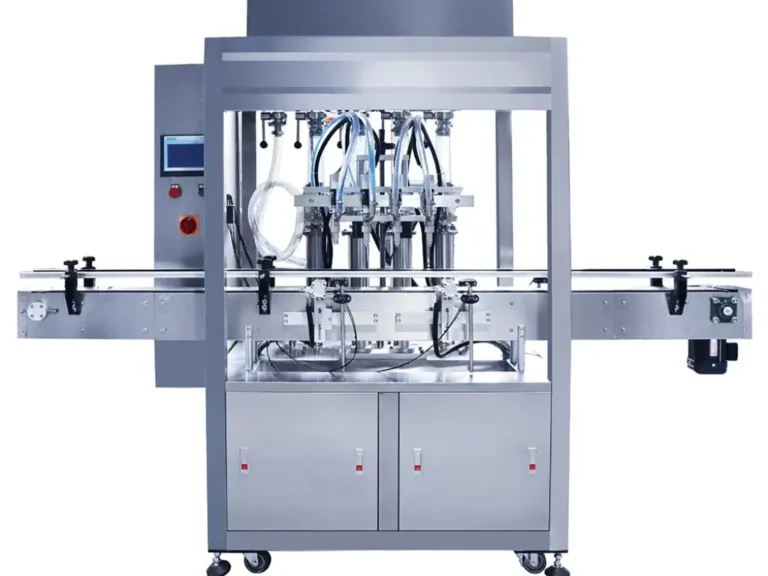

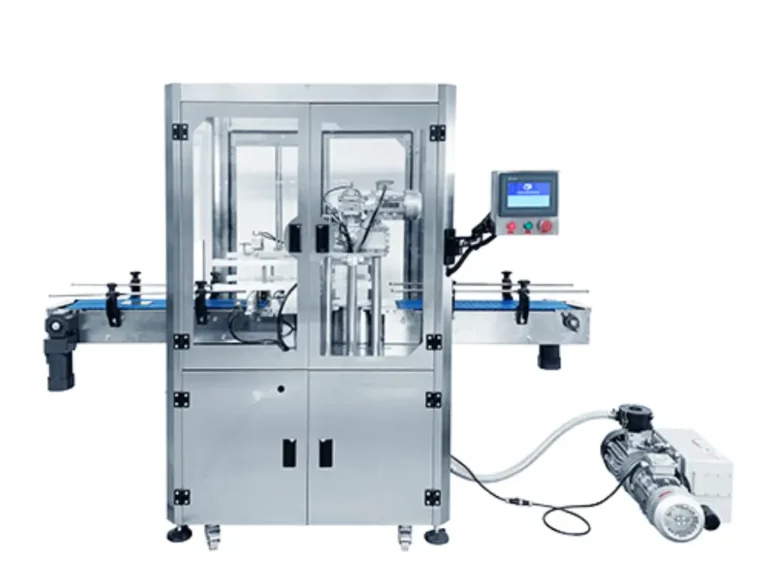

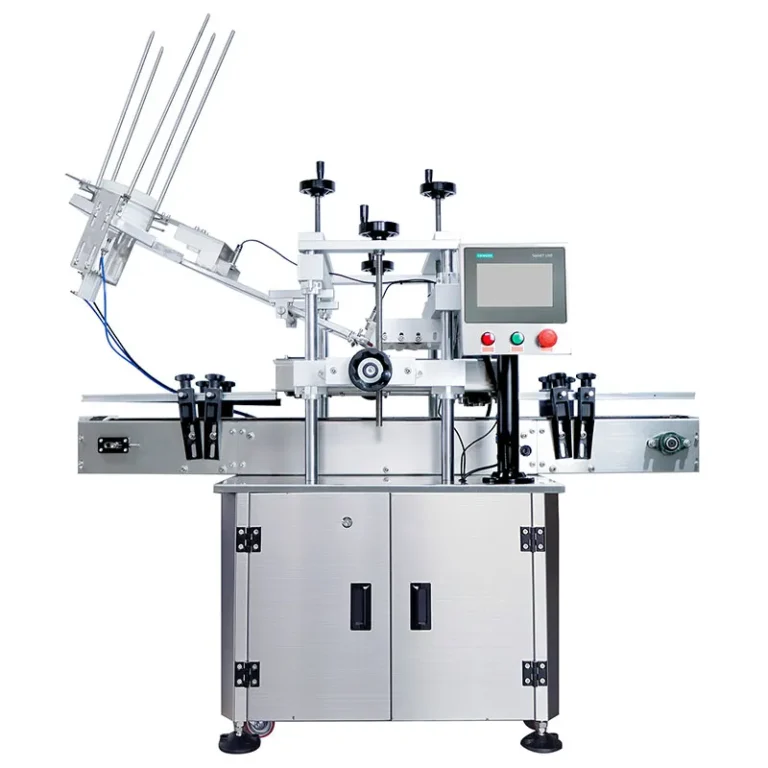

In the field of advanced packaging technology, Levapack provides solutions that directly solve the complicated issues faced by food manufacturers. Since 2008, precision and efficiency are the main traits of each machine with 18 years of niche experience in canning, filling, and packaging equipment. Our goal is to become part of your business success, selling products in more than 100 countries.

Our machines are state-of-the-art automatic canning and sealing machines that are designed to be highly precise and fast, eliminating the problem of inefficient packaging and product waste head-on. High-tech filling systems reduce both expensive overfills and underfills, providing continuity in the integrity of the product. Our equipment is designed using food-grade 304/316 stainless steel and international brand components, which seriously minimizes the problems of uneven seals or contamination and maintains the best food safety standards. Levapack is more flexible and allows a quicker changeover with highly customized solutions to different products and packaging formats. An investment in Levapack machines will result in long-term savings in terms of labor reduced, minimal waste of materials and energy use, and a definite ROI. Call us today and see how Levapack can change your food packaging line with their innovative solutions.

Cost Reduction and ROI: The Business Impact of Smarter Packaging

Investing in advanced packaging technology is not only operational, but a strategic financial move. Production problems can be solved through smarter packaging, and this can directly impact your bottom line, resulting in huge cost savings and high Return on Investment (ROI).

- Reducing Material Waste and Rework

One of the advantages is that it reduces waste during production. Accurate filling eliminates overfills, and strong sealing reduces the rejection of packages. Early defects are identified by automated inspection throughout the manufacturing process. Each piece of material and unit of the product saved directly reduces costs.

- Lowering Energy Consumption

Contemporary equipment is power-efficient. Smart power controls, smart power management, faster cycles, and optimized motor controls reduce the energy consumed per unit. With the increase in energy prices, cost-effective efficiency improvements can result in large savings, increasing sustainability and cost-effectiveness.

- Saving on Labor Costs

Although the initial cost of automation is high, the long-term labor cost is saved to a significant extent. Automated lines require reduced operators in simple activities that allow employees to perform complex supervision. This counters the shortage of labor and maintains a steady production.

- Increasing Production Capacity and Throughput

Advanced packaging lines considerably increase production capacity by reducing downtime and speeding up changeovers. This will enable fulfilling the increased demand without the need to invest in additional space or lines, which will maximize the output of assets. Increased throughput is directly proportional to increased sales.

- Shortening Time-to-Market

Packaging is essential for a fast response in the market. The ability to perform faster changeovers and dependable production implies that the new products arrive in the market faster. This pace is a huge competitive edge, which allows the companies to take the market share and react to consumer trends.

- Calculating and Realizing ROI

The positive gains are measurable. ROI analysis factors in investment versus savings through waste reduction, savings in labor/energy costs, throughput, and recall-cost avoidance. Numerous contemporary solutions demonstrate quick payback and are a great financial investment in the long run to achieve profitability.

Conclusion

The complexities of the contemporary production, especially in the challenging sphere of food packaging, require a strategic transformation instead of insignificant changes. Whether it is the intricacies of international supply chains and workforce relations or the growing pressure to achieve sustainability and absolute quality, businesses are faced with a crossroads. It is beyond any doubt that the road to resilience and long-term profitable operations is paved with the help of highly developed technologies, streamlined operation methods, and simulation methods.

The adoption of automation, the use of data analytics, and the dedication to continuous process improvement cease to be choices but rather the pillars of competitive advantage in tackling quality problems. Good practice is not only the first step towards minimizing waste, improving efficiency, and ensuring product safety, but the very foundation where a strong brand and a healthy bottom line are made. In the future, the players who are proactive enough to invest in smarter packaging solutions will be in the best position to withstand any disruptions, take advantage of any opportunities and become market leaders in a constantly dynamic market. The issue that every food manufacturer has to face is how and when they will respond to these quality problems, not whether they will do it.