When one would be asking a pouch packing machine price, the answers will be in a very wide range. That is because the term encompasses a wide range of equipment, including simple tabletop systems to complex, high-speed automated systems. The cost of a pouch packing machine is directly determined by its technology, abilities, and size.

A startup automating something for the first time has very different needs from an industrial facility that produces thousands of pieces an hour. This guide sheds light on this subject by explaining the aspects that are used to come up with the final price of a machine. It will also prepare you to determine your needs, pose the necessary questions, and make an informed buying decision by explaining why the costs vary.

What is the Real Cost of a Pouch Packing Machine?

To give a concise ground to begin, the main question should be answered directly. Although the pouch packing machine price is not standardized, a pouch packing machine can be categorized into specific ranges depending on its main objective and the level of automation. The two aspects are the major forces behind the initial investment.

The table below is a general overview of the market to allow you to place your expectations and understand how various solutions are positioned.

| Machine Type | Typical Price Range (USD) | Best For |

| Semi-Automatic Premade Pouch Filling Machines | $5,000 – $15,000 | Startups, small-batch producers, R&D labs, and businesses transitioning from manual packing. |

| Automatic Premade Pouch Machines | $25,000 – $80,000+ | Small to medium-sized enterprises (SMEs) need consistent quality, higher speeds, and operational efficiency for pre-made bags. |

| Vertical Form-Fill-Seal (VFFS) | $30,000 – $120,000+ | High-volume production of simple pouch styles (like pillow bags) for products like snacks, powders, and granules. |

| Horizontal Form-Fill-Seal (HFFS) | $80,000 – $250,000+ | Demanding, high-speed applications, often for stand-up pouches with zippers or complex shapes, are common in the premium food sector. |

The pouch packing machine price range is wide, as can be seen in the table, with several thousand dollars to more than six figures. These are not random numbers; it is a direct reflection of the engineering capabilities of the machines and the level of technology that each machine possesses.

What then is the force behind such huge price variations? Now, let us decompose the exact factors that will result in the final price tag.

Key Factors That Drive the Final Price

The end cost of a pouch packing machine depends on a variety of technical requirements and optional extras. It is important to have a clear knowledge of these elements to enable you to assess the quote of a supplier well and to make sure that your investment is based on your operational needs. The main factors that contribute to the cost of the machine are as follows.

Automation Level

The level of automation directly depends on the investment it requires and the possible production output.

- Manual: The entire process, such as measuring, filling, and sealing of products, is conducted by a person. This is the cheapest in terms of capital cost but has limitations in speed, consistency, and scalability.

- Semi-Automatic: The device carries out major operations such as filling and sealing, but it needs an operator to handle such functions as pouch handling. This provides a huge gain in consistency and a moderate gain in speed.

- Fully Automatic: The machine does the whole process of packaging, including feeding the pouch, filling, sealing, and discharging without human interference. This has the greatest initial cost but offers the fastest production rate, easy operation through the use of a touch screen, and also offers consistency and the lowest cost of direct labor.

Machine Configuration (Rotary vs. Inline)

The internal mechanical layout is a key cost factor for automatic machines that handle pre-made pouches.

- Inline Configuration: The pouches are transported in a linear path between stations. This design is often more compact and can be a cost-effective solution for achieving full automation.

- Rotary Configuration: The pouches are indexed around a circular turret to various processing stations. This architecture allows greater speed of operation and may support more functions in the machine’s cycle, but it usually leads to an increased cost of equipment.

If you’re unsure about which packaging machine configuration to choose, you can explore our detailed article on ‘Linear Vs Rotary Packaging Machine: How to Choose the Right One?‘ for more insights.

Packing Speed (Bags Per Minute – BPM)

The highest speed of output of a machine is a direct consequence of engineering, motor capacity, and sophistication of control systems. A machine that is built to handle 100 BPM needs better mechanical parts, higher-level servo motors, and a more elaborate program than a machine that is built to work at 30 BPM. This engineering and construction variation explains why there are huge differences in cost between the low-speed and high-speed models.

Filling System

The measuring and dispensing system of the product is also an important part of the system, which has a great influence on the overall cost of the machine. The physical properties of the product to be packaged determine the choice of the appropriate filling device.

- Auger Filler: It is used with powders (e.g., flour, spices), and it works using a rotating screw, so it can dispense a specific amount of volume.

- Volumetric Cup Filler: A cost-effective, high volume method of filling free-flowing, uniform granules of similar size (e.g., rice, beans).

- Liquid & Paste Pump: Necessary when dealing with liquids and viscous products (e.g., sauces, gels), where special pumps and nozzles are needed so that they correctly and non-drip dispense.

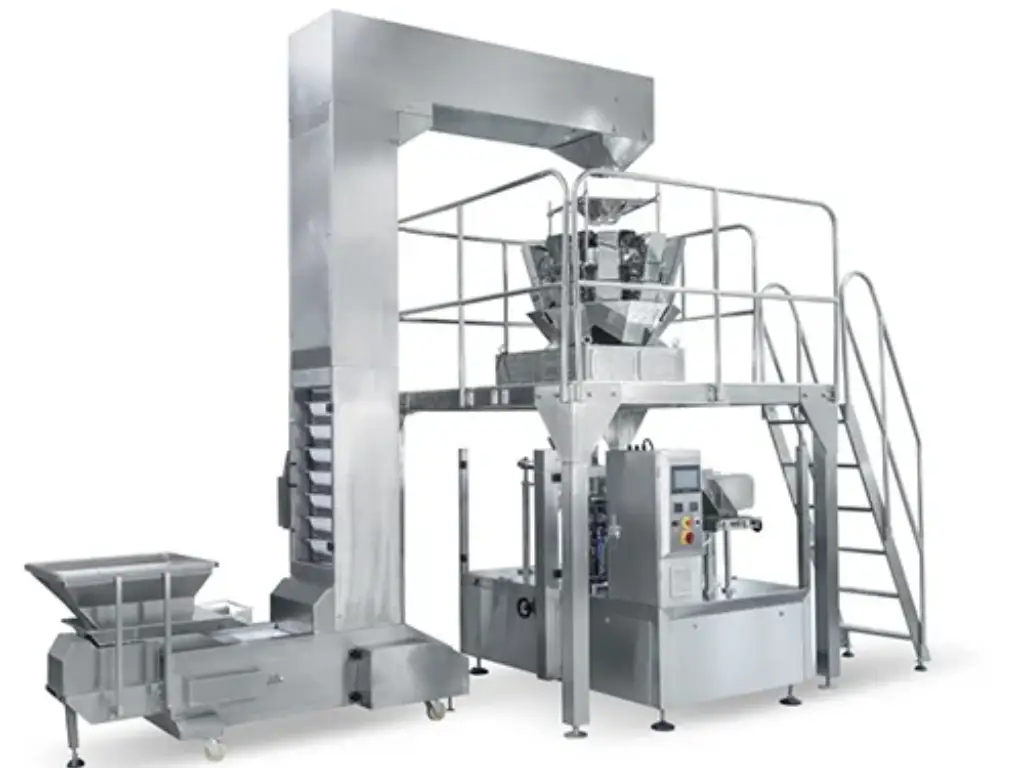

- Multi-Head Weigher: The most precise weighing system of solids and products of irregular shapes (e.g., snack foods, confectionery). It employs an advanced algorithm and several weighing buckets to produce an accurate target weight. A multi-head weigher in itself is a very expensive component, and this makes it a huge contributor to the total price of the system.

Pouch Specifications

The packaging design is complex and variable, and this directly affects the machine specification and the cost. A stand-up pouch with a zipper or custom shape is a more challenging pouch to engineer a machine to handle, so more sophisticated grippers, suction, and control systems are needed than a machine designed to handle a simple flat pouch. The versatility of the machine, being flexible to work on most sizes of pouches, also contributes to its complexity and cost.

Additional Functions & Integrations

A standalone machine may be upgraded to include subsystems, making it a complete packaging system. Every addition will raise the end cost:

- Date Coder: (e.g., Thermal Transfer, Inkjet) For applying lot codes and expiration dates.

- Gas Flushing (MAP): A system of Modified Atmosphere Packaging that utilizes an inert gas to increase the shelf life of products.

- Label Applicator: For automated application of pressure-sensitive labels.

- Quality Control Systems: Integration of a metal detector or check weigher to automatically inspect and reject non-conforming packages.

Construction Materials & Components

The durability, reliability, and fit in a particular environment of the machine depend on the quality of materials and components.

- Construction Material: Although food-grade stainless steel SS304 is standard, a change to SS316 stainless steel is required where there is a possibility of using corrosive or acidic products, which raises the material cost.

- Core Components: Core components are made of industrial components of widely known brands (e.g., Siemens, Mitsubishi, SEW, Schneider), which are more expensive initially but lead to a more reliable operation, easy maintenance, and overall reduced cost of ownership over the lifetime of the machine.

Construction & Components

The quality of what you can’t easily see matters immensely.

- Materials: A machine built with SS304 food-grade stainless steel is standard. For corrosive or highly acidic products, an upgrade to SS316 stainless steel is necessary and more expensive.

- Components: The brands of the core electrical and pneumatic components are a direct indicator of reliability. A machine using world-class components like Siemens or Mitsubishi PLCs, SEW motors, and Schneider electricals will cost more upfront than one with generic parts, but it promises far greater stability and a lower total cost of ownership.

How to Choose the Right Machine for Your Needs

The purchase of the right machinery is a strategic process that goes beyond a mere price comparison. Success will come with a clear definition of the technical and operational requirements of your project before meeting with suppliers. This preparation will help you get the relevant proposals and make an informed decision. This is a systematic study of your operation that may be decomposed into the following main areas.

The first step you should take is to examine your product and its packaging. Start with the physical characteristics of your product- is it a powder, granule, liquid, or solid? Think of its specific product characteristics: is it fragile, sticky, or corrosive? Then describe the pouch itself. State its type, e.g,. stand-up or flat bag, and anything special, e.g., zipper or spout. The sizes of the pouch and the material structure are also important, as they determine the requirements of the machine directly.

Second, measure your production and financial objectives. Find your desired output rate in BPM or units/day. It is important to think about your present needs, but also your future development in the next two to three years, so that the machine will be a valuable asset. At the same time, create an effective budgetary structure, including the initial capital investment in the machine as well as the expected long-term operation costs.

Lastly, evaluate the limitations of your facility. Take the physical footprint of the space that can be occupied by the new equipment to make sure that it fits properly in your production line. Another thing you need to ensure of is that your facility has the appropriate industrial utilities, such as the proper electrical power supply and sufficient capacity of compressed air, which is needed to run most automated machines.

By doing this thorough analysis, you will have a specific project specification. Armed with this, you can now go into the suppliers with the confidence of knowing whether you require a semi-automatic auger filler to fill a low-speed powder or a more sophisticated rotary machine to fill a high-speed, complicated pouch.

Calculating Your Return on Investment (ROI)

A packaging machine is not a cost center; it is an asset that brings income. The most important figure you will ever compute is not the packing pouch machine price, but the number of years it will require to pay its price, and start making you money. This is your Return on investment (ROI).

This is simple mathematics:

ROI = (Financial Gain – Investment Cost) / Investment Cost

The key is to accurately quantify the “Financial Gain,” which is composed of several elements:

- Labor Cost Savings: This is the direct return. Take the annual salary (with benefits) of the manual packers you will replace or reassign and compare it to the annual operating cost of the machine.

- Increased Production Output: Once you can increase the production output, say, 1000 units to 5000 a day, what is the extra profit on the 4000 units?

- Reduced Material Waste: Automatic fillers are much more precise in comparison to manual scooping. Even a 1-2 percent decrease in product giveaway per bag can amount to thousands of dollars in savings per year.

- Improved Product Quality & Consistency: A perfect seal every time reduces spoilage and customer returns. This saves your brand image and the expenses of replacing the damaged products.

To illustrate this principle, consider a hypothetical case: a medium-sized coffee company spends 45,000 dollars on an automatic pouch packing machine to substitute a manual operation.

In the past, manual packing of the company was being done by two employees, which constituted an annual labor cost of 70,000 dollars. This labor can be redeployed with the introduction of the automated system, and this results in an immediate benefit of operational efficiency equal to the cost.

Moreover, the accuracy of the machine in filling pouches of coffee beans eliminates the wastage of coffee beans through overfill, hence an estimated material savings of 8,000 dollars per year. The higher speed and capacity also enable the company to seek and win new wholesale contracts, which is expected to bring an additional 20,000 dollars in annual profit.

The sum of these two figures is the annual financial benefit, which can be attributed to the new machine, and it equals $98,000. The analysis shows that ROI in the first year will be 117% when compared to the initial investment of 45,000 dollars. This strong outcome proves that the equipment pays itself off within less than six months, and it also becomes a substantial profit center, which proves the strategic choice to spend funds on automation.

Beyond the Sticker Price: Uncovering Total Ownership Costs

In a strategic investment analysis, the question is not how much the equipment will cost, but what the total financial effect of that equipment will be throughout its life. This is an all-inclusive view that is referred to as the Total Cost of Ownership (TCO). It is important to understand the TCO because a cheaper machine can be easily neutralized by high costs of operation or maintenance.

To perform an in-depth TCO analysis, you should concentrate your analysis on the following three important cost areas, which tend to increase the initial sticker price by a large percentage.

Acquisition and Deployment Costs

This type consists of all the one-time costs to make the machine fully operational. They are not included in the base pouch packing machine price, but they are required to deploy.

- Shipping & Installation: International freight, customs clearance, and professional on-site installation with a certified technician, plan to spend an estimated $2,000 to $7,000, depending upon location and complexity of the machine.

- On-site Training: Detailed operator and maintenance training is essential. Some suppliers incorporate this, others will add a cost of $500 to $3000 plus travel costs to have a multi-day session.

Ongoing Operational Costs

These are the fixed costs of the daily use of the machine that directly affect your profitability.

- Energy Consumption: Although a line in your utility bill, an efficient machine will save you hundreds or even thousands of dollars annually as compared to an older, less optimized one.

- Spare & Wear Parts: In any automated machine, you can expect to spend between 1-3 percent of the initial cost of the machine per year, replacing the usual wear parts such as belts, heaters, grippers, etc. On a machine costing $50,000, this would be $500 – $1500 per year.

Long-Term Maintenance and Support

This type includes the system of maintaining your machine reliably. Although not necessarily a direct annual expense, the unsupportiveness can be the most costly aspect of all.

- Preventative Maintenance Visits: A yearly service call by a technician can be anywhere between $1,000 and $4,000 plus travel, but it can save the cost of emergency breakdowns that are much more expensive.

- Emergency Support: The real cost in this case is downtime. When a machine fails without the availability of a reliable remote or local support, production loss can be costly, to thousands of dollars a day. This risk is a serious form of insurance that should be mitigated by investing in a supplier who has good and readily available technical support.

With the consideration of these TCO estimates, it is possible to observe how a machine that is a bit more expensive at the outset but that includes training and is more energy efficient can ultimately be the cheaper option.

New vs. Used Machines: A Cost-Benefit Analysis

One of the questions that may often arise in the procurement process is whether to invest in a new machine or to buy a used one in order to cut the initial capital outlay. Although it is tempting to buy a cheaper product at a lower initial cost, it is important to conduct a detailed cost-benefit analysis since the consequences of this action can have a considerable impact on your efficiency and overall profitability.

A used machine can often be acquired for 30-50% less than a new equivalent, which can be a compelling option for businesses with immediate budget constraints. Nevertheless, this short-term saving should be balanced with several serious risks that may result in increased long-term expenses.

To make this comparison clear, we should discuss the main differences:

| Feature | New Machine | Used Machine |

| Initial Cost | Higher initial capital investment. | Lower upfront purchase price. |

| Warranty & Support | Includes a full manufacturer’s warranty (typically 12+ months) and direct access to technical support. | Typically sold “as-is” with no warranty. All repair costs and production losses are borne by the buyer. |

| Condition & History | Brand new, with all components at 100% of their operational life. History is known and documented. | History is unknown. May have significant wear, hidden defects, or a history of poor maintenance. |

| Technology & Efficiency | Features current technology, superior energy efficiency, higher precision, and compatibility with modern packaging materials. | Often uses outdated technology, resulting in lower efficiency, more material waste, and limited capabilities. |

| Spare Parts Availability | Guaranteed availability of all spare and wear parts directly from the manufacturer. | Spare parts may be difficult or impossible to source, especially if the model is discontinued. |

| Customization | It can be fully customized by the manufacturer to meet specific product, pouch, and production line requirements. | Customization is generally not feasible. The machine is a fixed asset that may be difficult to integrate. |

A used machine could be a risk calculated when the needs are very low and the downtime is not crucial. However, in any serious, expanding business, in which production uptime and reliability are the most important factors, the stability and support of a new machine are nearly always the smarter long-term choice.

Levapack: Your Custom Partner for Pouch Packaging Success

The last and most important thing you should do in your investment process is to select the right supplier. Having discussed the aspects that define a pouch packing machine in terms of price and value, the best partner will give a clear, trustworthy, and high-performance solution.

This is what Levapack has to offer. Our premade pouch packaging machines are designed to perfection, having 18 years of dedicated experience. We take your TCO issues seriously by employing high-quality 304/316 stainless steel and internationally known parts such as Siemens PLCs and SEW motors, which guarantee a long life. Our accuracy manufacturing, which is tested by the rigorous 36-hour aging tests, ensures the performance stability every day.

You may require a reliable off-the-shelf model or a customized OEM/ODM product with such features as nitrogen flushing, and our engineering department is standing by to provide you with the product to fit your particular requirements. Our equipment is supported by a 12-month warranty and lifelong technical support.

Get your custom quote with no obligation today by contacting the Levapack team and see how our experience can make you successful.