Introduction

As any successful product grows, eventually, a bottleneck is created by manual or obsolete packaging systems. This directly results in limited production, rising labor costs, and product inconsistency in terms of presentation, which jeopardizes growth in the future. The ultimate answer is the automated packaging line that is connected to the modern automation systems.

Nonetheless, the very design and funding of such a system is a significant strategic choice that needs to be clear and expert. This guide gives just that. It is not a list of products, but a thorough strategic plan. We will address in a systematic fashion core machinery, critical design factors, budget, ROI analysis, and supplier selection. What we want to do is give you the knowledge to design an optimum line that will address today and tomorrow.

What is a Packaging Production Line?

A packaging production line is a combined packaging system of machines that automates the consecutive process of preparation, filling, sealing, labeling, and palletizing a product to be distributed. It guarantees a seamless movement of products from the raw product to the finished goods, which are ready to be shipped. The system also assists in providing the best user experience by keeping the presentation and quality of products.

The main purpose of a packaging production line is to perform such tasks at high rates of speed, accuracy, and consistency. The system can be used to convert a finished good into a marketable product with the minimum amount of human involvement and maximum efficiency by integrating specialised equipment, such as bottle unscramblers or robotic palletisers.

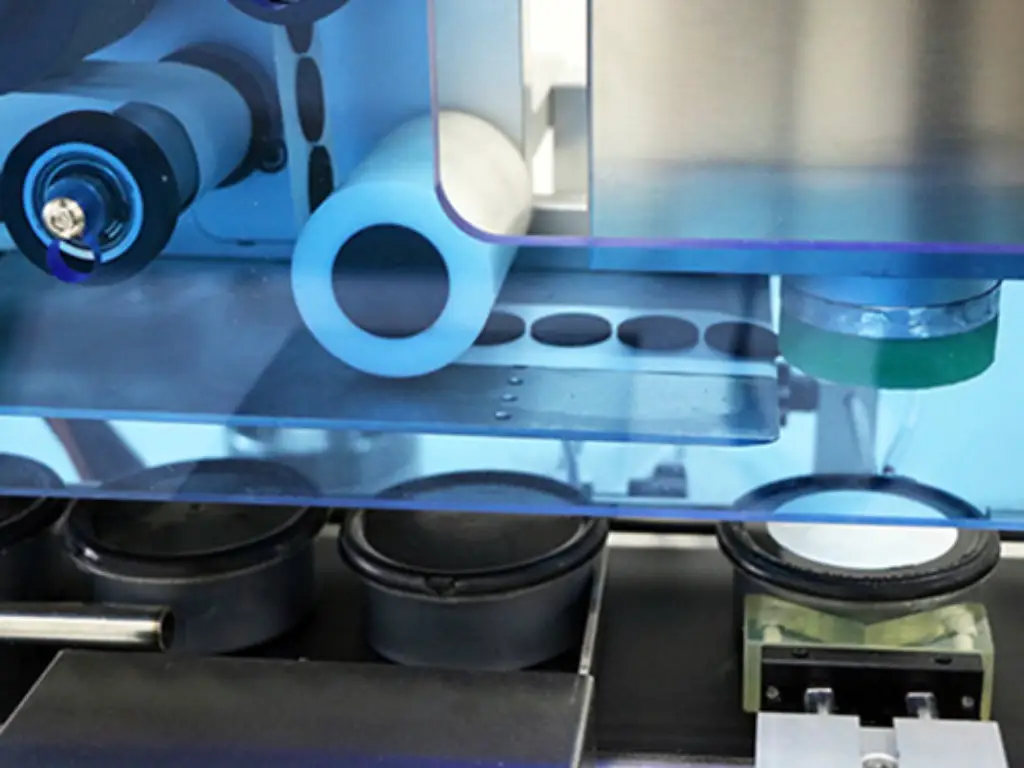

Core Machines: The Building Blocks of Your Line

The performance of a packaging production line is essentially dependent on its components. Although each line is tailor-made, they are all built out of a pool of core machines, each designed to perform a particular duty. To design an efficient and suitable system for your product, a good knowledge of these building blocks is important. These machines can be classified according to their major role in the packaging production line.

Infeed & Preparation

This is the first step that defines the whole process. It is intended to receive bulk and empty containers and make them ready to be filled in a smooth and hygienic way.

- Bottle Unscramblers: These machines take bulk-loaded containers and orient them using either mechanical or centrifugal force to present them uniformly to be discharged onto a linear conveyor, and this forms the foundation of automated infeed.

- Rinsing & Washing Machines: Essential for sanitary applications (food, beverage, pharma), these machines decontaminate containers before filling. Systems range from ionized air rinsers for particulate removal to full wet-wash stations using purified water or sanitizing agents for microbial control.

Product Filling

The most important element of product-cost control is the filler, since the volumetric or gravimetric accuracy of the filler determines the profitability. The rheology (viscosity), specific gravity, and other physical characteristics of the product determine the choice of filling technology.

- Piston Fillers: This type of volumetric system provides high-accuracy fills by moving a piston in a calibrated cylinder. They have a very good positive displacement mechanism and are the perfect choice when dealing with high viscosity liquids and semi-solids like creams, pastes, and gels.

- Gravity Fillers: These are level-filling or gravimetric fills in which the product is released into the container through a reservoir. Being a cost-effective technology, they are most appropriate to non-carbonated, low-viscosity liquids with predictable flow properties, such as water, juices, and thin solvents.

- Pump Fillers: These systems employ a wide range of pump technologies (lobe, gear, peristaltic) to pump product, and have outstanding versatility and volumetric precision over a wide range of viscosities. This design renders them very useful with a variety of products, including those containing suspended solids, that are subjected to very close volumetric accuracy.

Sealing & Capping

The step uses the main closure, which is product integrity and shelf stability.

- Capping Machines: Systems designed for cap application and torquing. Spindle cappers utilize rotating discs for high-throughput screw cap application. Chuck cappers provide superior torque precision via a gripping mechanism. Snap cappers apply press-on style closures.

- Induction Sealers: Employ a non-contact electromagnetic field to heat-fuse a foil-based inner seal to the container’s land area. This process creates a hermetic, tamper-evident seal.

Labeling & Coding

This module uses product identification, branding, and variable data to trace.

- Pressure-Sensitive Labelers: Affix self-adhesive labels that are in the form of a web roll on containers. The systems can be used with high flexibility to different label formats ( wrap, front/ back, top/ bottom) and container shapes.

- Inkjet & Laser Coders: Added to the line to print variable data (e.g., lot codes, expiration dates). High-speed non-contact printing is standard in Continuous Inkjet (CIJ). Laser coders vaporize the substrate surface to form a permanent mark that can not be removed.

End-of-Line Packaging

This last sequence mechanizes the collection and assembly of primary packages to secondary and tertiary packaging processes, which guarantees protection and logistical effectiveness.

- Case Erectors & Packers: Automatic systems that assemble corrugated cases out of flat blanks, then pack those with a pre-determined number and pattern of product, making them compatible with the up- and downstream operations in the larger conveyor system.

- Case Sealers: Use adhesive tape or put hot-melt glue on the top and bottom flaps of filled cases. These systems are more frequently coordinated with automatic stretch wrappers to fix the load efficiently.

- Palletizers: Place finished cases on a pallet in a specific matrix pattern. Robotic palletizers are best suited where there is maximum flexibility in pattern formation and also when there are multi-line or complex handling needs. More sophisticated systems are also able to include a stretch hood or pallet entry modules to maximize wrapping and load stability.

Key Factors for Your Packaging Production Line Design

An effective packaging production line does not mean purchasing the most expensive machinery, but it means purchasing the correct machinery to fit your particular requirements. To come up with the best decisions, you need to consider four important factors carefully that will determine your whole project.

- Product and Container Details:

The most important thing is your product and its container. The nature of the product will also define the nature of the filling machine required, like whether the product is a thin liquid or a thick cream, or whether the product contains solids. Similarly, the material of the container (glass, plastic), its shape, and size will determine the appropriate equipment to use to handle, cap, and label. Never fail to give physical samples of your products and containers to potential suppliers.

- Required Production Speed:

You have to calculate the number of products that you require to package in a minute or an hour. This figure, commonly referred to as CPM (Containers Per Minute), has a direct effect on the degree of automation and the line price. Low-speed line (e.g., 20 CPM) and high-speed line (e.g., 150 CPM) are fundamentally different. Plan not only what you need now but also what you are expected to grow into within the next three to five years.

- Factory Layout and Space:

It has practical constraints provided by your available space. You need to be sure of the measurements of your production space, floor space, the height of your ceiling, and where you have a pillar or a doorway. Also, one should think of the availability of utilities required, such as electricity, compressed air, and water. This information will guide a good supplier to come up with a layout that will help the line to fit and leave sufficient space to allow operators and maintenance.

- Future Growth and Scalability:

Think ahead so you do not have to make expensive adjustments in the future. An intelligent design has an expansion capability and compatibility with newer automation systems or improvements in the conveyor systems. Include sustainability in the material selection and energy-efficient equipment in your long-term planning strategy.

Automatic vs. Semi-Automatic: Making the Right Choice

One of the main strategic choices in line design is the degree of line automation. This decision has a direct impact on capital investment, the cost of labor used in operations, and output. Neither of these approaches is universally best, and the best option depends on production needs, product mix, and the size of the business.

To make the comparison clear, let us make it in a table.

| Feature | Semi-Automatic Line | Fully Automatic Line |

| Investment Cost | Lower initial capital outlay. | Significant initial capital investment. |

| Operating Cost | Higher long-term labor costs due to operator dependency. | Substantially lower labor costs per unit produced. |

| Efficiency & Output | Lower, operator-dependent output (typically 5-25 CPM). | High, consistent, and predictable output (30-300+ CPM). |

| Flexibility | High flexibility with rapid changeovers for small, diverse batches. | Lower flexibility; changeovers can be more complex and time-consuming. |

| Ideal Scenarios | Startups, contract packagers, small-batch production, and operations with numerous SKUs. | High-volume manufacturing, established product lines, and operations focused on minimizing unit cost. |

Your operational model is the main driving factor behind the decision. A semi-automatic line is a great advantage to businesses that manufacture a large number of SKUs in small volumes. On the other hand, in those operations involving high volume production of a small range of products, the productivity and low unit cost of a fully automatic line offer an unambiguous and strong payback.

Estimating Your Project Budget

After defining the level of automation, it is possible to define a reasonable budget for the packaging production line project. The difference between semi-automatic and full automatic does not only influence the costs but also determines the whole direction of the project and certain demands on the line project.

The full financial plan does not only refer to the cost of the machines. The total price is the sum of several important elements:

- Hardware: The money spent on the single machines.

- Software & Integration: The price of control systems and engineering to get the sync line.

- Installation & Commissioning: On-site installation, calibration, and validation by qualified technicians.

- Training: Operator and maintenance training.

- Logistics: Shipping, rigging, and placement of equipment costs.

When these elements are weighed against each other, investment levels become apparent, which relate precisely to the complexity and production of the line. These broad ranges can be used to set the stage for early finances:

- Entry Level Semi-Automatic Line: In simple set-ups, the investment in the project is usually between $30,000 and $80,000.

- Mid-Range Fully Automatic Line: An integrated line with increasing hardware expense, integration complexity, and full support services will typically have an investment of between $150,000 and $400,000.

- High-Speed, High-Specification Line: In demanding applications where superior machinery, validation, and a lot of engineering are necessary, the total venture expenses can surpass half a million dollars.

How to Choose a Reliable Supplier?

Supplier selection is a critical element of the long-term success of a packaging project or a new packaging line. Besides technical abilities, they should also be compatible with what you already have and give insights into sustainability strategies.

- Technical Expertise & Application Knowledge: The supplier should be able to show a profound knowledge of your particular industry, product, and operational issues. They ought to have the ability to technically defend their equipment suggestions against other technologies.

- Project Management & Communication: An effective supplier will assign a project manager, a project timeline (Gantt chart), and a communication protocol. This brings transparency and accountability between the purchase order and the end installation.

- Proven Performance & References: Ask for case studies and performance data of installations like yours. A good supplier can easily give you references of clients that they are currently serving so that you can check their claims and the quality of their services.

- In-House Capabilities vs. Integration: Find out whether the supplier is a single-source manufacturer, who designs and constructs its own equipment, or an integrator who puts together components of different brands. A single-source manufacturer is able to provide a more streamlined design, service, and support.

- After-Sales Support & Service Level Agreements (SLAs): Assess the design of their after-installation support. This covers the warranty conditions, the response time of technical support, and the availability of the important spare parts. A good after-sales service is important in reducing operational downtimes.

- Factory Acceptance Test (FAT) Protocol: The supplier has to agree to perform a full FAT. This means that the entire integrated line is assembled and tested on their premises (using your specified products and containers), and only after it has passed the tests, it is released to be shipped. This pre-shipment verification is an important process in reducing risks in the on-site commissioning.

Levapack: Your Partner in Turnkey Packaging Solutions

The ability to meet these demanding standards is the main essence of our mission at Levapack. Having more than 18 years of expert experience in can filling and seaming technology, we are a one-stop manufacturer with an area of 4000 ㎡ , with advanced CNC machining. This enables us to manage quality to 2m precision and have quick turnaround on standard and special lines.

We are also dedicated to being the best, and this is evidenced by our high-quality parts (Siemens, SMC, SEW) and our thorough quality assurance, which includes an aging test of all our machines at 36 hours. Our solutions to the world food and beverage manufacturers and OEM/ODM customers include CE/ISO/CSA certified standalone machines to complete turnkey lines with solids, powders, and liquid food and beverage products. We not only supply equipment but also offer a partnership based on reliability and performance with a strong global service network and an extended 12-month warranty.

Are you willing to talk about a solution that can satisfy your high standards? To get an individual consultation and packaging production line layout scheme, get in touch with our engineering department today.

Industry-Specific Considerations and Examples

As much as the fundamental concepts of automation are global, the ultimate design of a packaging line should comply with the regulatory and operational requirements of the target industry. These codes tend to be non-negotiable and determine materials, design, and documentation.

Food & Beverage

Sanitary design to avoid microbial contamination is the guiding principle. The packaging production lines should be designed in such a way that they are accessible and easy to clean. This requires stainless steel construction (usually grade 304 or 316L on product contact surfaces), the removal of recesses or flat surfaces where product can build up, and sometimes has built-in Clean-in-Place (CIP) lines. These automated systems circulate cleaning and sanitizing solutions throughout the entire product path, and guarantee reliable and provable hygiene without the need to disassemble manually.

Pharmaceuticals & Nutraceuticals

There are stringent international regulations that guide this industry, and these are mainly Good Manufacturing Practices (GMP). Conformance is necessary. Equipment has to be built using approved materials and must be sterile or nearly sterile in design. Validation is the most important prerequisite. The whole packaging production line has to be validated in a formal way, which is documented in IQ (Installation Qualification), OQ (Operational Qualification), and PQ (Performance Qualification) procedures. Moreover, the systems should accept compliance with 21 CFR Part 11 regarding the electronic records and signatures and combine the serialization and track-and-trace to provide product traceability.

Cosmetics & Personal Care

This business is noted for the viscosity of its products and the wide range of packaging. The packaging production line design should overcome the challenge of working with high-viscosity creams and lotions that usually necessitate special positive displacement fillers (e.g., piston fillers) with heated hoppers and agitated reservoirs to ensure consistency of the product. The machinery should also be very flexible to allow a large variety of different shapes and sizes of containers. This requires soft handling systems and quick changeover with no tools to reduce the downtime between runs of different SKUs.

Conclusion

The strategic project of designing and implementing a packaging production line is very critical. The success of this is not based on the individual machines but on a methodical approach that is tailored to match equipment potential with particular operational and financial objectives. This guide has given an in-depth model of this process, including the basic technology, design issues, budgeting, and supplier selection.

Using these principles, you are now in a position to cut through the maze of automation with a level head and open eyes. This should be followed by translating this knowledge into a detailed project plan for your organization. When upgrading an existing packaging system or creating a new packaging production line methodical and well-researched approach is the crux of a successful investment. To receive assistance according to your particular needs in food, reach Levapack now.