Modern consumers want “clean label” products that lack preservatives, and this has changed the marketing landscape for the food and beverage industry. This demand leads to one of the biggest questions for food and beverage manufacturers: how to balance additive-free products to achieve long, ambient shelf life. Hot filling technology continues to provide one of the highest “shelf life” ratios without the use of preservatives.

Obtaining a hot filling machine is not a simple purchase. It involves engineering and has an effect on the quality of the product, capital investments, operational expenses, and costs. This guide focuses on the hot fill process, its elements, and its uses for high-acid beverages and complex glass jars food products.

What is a Hot Filling Machine?

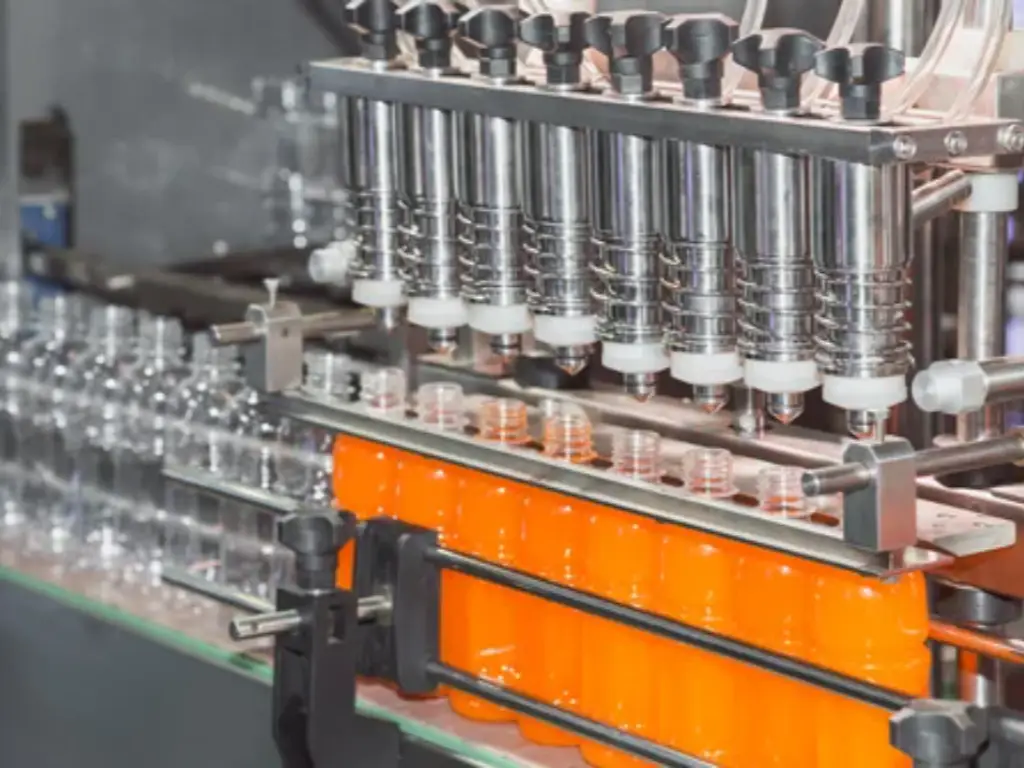

A hot filling machine is a special kind of bottle-filling machine that is used to fill liquid food substances, which include juices and sauces, as well as drinks, at hot temperatures. The concept of the hot fill is not complicated but still ingenious, namely, heat the product to a high temperature that will destroy the harmful bacteria and microorganisms, and then pour it into sterilized glass bottles or PET bottles and seal. After filling, the filling containers are cooled to room temperature, which guarantees product safety and extended shelf life.

Imagine that it is a two-in-one operation: sterilizing and packaging. At the appropriate moment, when a hot liquid is poured into a container, e.g., fresh fruit juice or hot sauce, it destroys any remaining microbes. This will not only improve the quality control but will also preserve the product properties like the taste, color, and aroma.

The typical process of filling is hot filling, which needs a stainless steel liquid filling machine that has precise valves and temperature-controlled mechanisms. Contemporary designs have the use of weight filling machines or liquid fillers, which ensure that the right amount of product is in each container. For beverage or food producers, mastering this approach means achieving high-quality, repeatable results in every batch.

Why Choose a Hot Filling System?

As part of the comparison of preservation technologies, a decision-maker tends to weigh hot fill against such options as aseptic filling or pasteurization-in-container. A hot-filling system has several commercial benefits.

- Capital Expenditure (CapEx) Efficiency: In comparison, a hot fill line, aseptic filling, will cost much less to install. Aseptic lines require a sterile-room environment, complicated chemical sterilization baths for packaging, and special air handling, which are expensive to construct, verify, and maintain.

- Proven and Robust Technology: Hot filling is a technology that has been well established and is mature. The engineering concepts are very sound, the equipment is durable, and operations training is not as rigorous as aseptic system training. This maturity is equivalent to the predictability of performance and maintenance schedules.

- “Clean Label” Market Alignment: This technology perfectly satisfies the first-order market demand toward products that are not chemically adulterated. It uses an ancient preservation technique- heat, in an extremely industrialized way. This improves the perceived quality of the product, and it goes in line with transparent branding.

- Technological Versatility: Although traditionally linked to beverages, the concepts of hot filling can be used on the product with great versatility, with regard to a variety of product properties, such as the differing viscosities, acidities, and even with small particulates.

The Complete Hot Fill Production Line

Purchasing a hot filling machine does not automatically address all production difficulties. In fact, a streamlined hot fill process depends on a fully integrated hot fill line. Every component, from rinsing all the way to case packing, needs to work together seamlessly. The progression of a product through a production line is not a linear set of obstacles. It is a continuous flow that actively maintains product safety and quality.

Bottle/Jar Rinsing and Preparation

We can begin with the very beginning, the containers. Bottles and jars do not come sterile, contrary to the common opinion. Unless handled, dust, moisture, and microscopic contaminants may compromise the safety of your product. This is the reason why the contemporary lines prepare containers with sterile air, filtered water, or ionized rinsing media.

This step is more critical in the case of working with PET bottles. PET Resin can only withstand the hot fill technology without being warped by using heat-set PET, a specific resin designed to withstand high temperatures. Each rinse and drying cycle should be timed well to ensure hygiene and production continuity. Skip or shorten this step, and even a high-quality filler can’t compensate for the risk of contamination.

The Filling & Capping/Seaming Unit

The next thing is the filling machine, which is the heart of the operation. The types of fillers that you may choose, depending on the nature of the product, include:

- Overflow or Gravity Fillers: Suited to liquids that are free-flowing, like juices, so that the top level of fillings is even and that it looks clean and uniform.

- Weight Filling Machines: The most accurate of these, the weight of the product is measured to regulate the amount of product dispensed. The approach reduces giveaway and enhances uniformity.

- Piston Fillers: Ideal with viscous products, such as hot sauce, purees, or condiments. These fillers work by involving a piston mechanism of product through pushing that product into place with accuracy, without disturbing the correct volume with increased viscosity.

Every liquid filler in a hot fill line must withstand high temperatures and be constructed from stainless steel (typically 304 or 316). This ensures hygiene, corrosion resistance, and long-term durability, which every customer values.

Containers are taken to the capping or seaming department immediately after the filling valves complete their job. Time is of the essence; it is essential to seal the product when it is still hot so as to create a hermetic seal. This helps to keep microorganisms out as well as ensuring the safety of your product at the earliest stage.

The Critical Role of the Cooling Tunnel

The importance of the cooling tunnel is often overlooked, but it is just as vital as any of the filling processes. When sealed, the product is still a heated fluid, which may still be around 85°C. If its heat is not managed, the contents will continue to “cook” and ruin the flavors, nutrients, and valuable aromas, all of which compromise the quality of the product.

To avoid this, bottles or cans that are sealed are transported through a tunnel in which they are increasingly sprayed by the increasingly cold water. The cooling of the temperature should be properly controlled; it should not be reduced marginally. The cooling should be regulated, effective, and regular.

This process accomplishes three things:

- Freezes the cooking effect, freezing the natural profile of flavor.

- Stops deformation, particularly in PET bottles that tend to become soft at high temperatures.

- Creates a vacuum seal, pulling down the safety button on the lid — a clear visual cue of a safe, properly sealed product.

In a nutshell, what converts a container full of fresh product into a safe and shelf-stable high-quality product is the cooling tunnel.

Downstream: Labeling and Case Packing

As the products reach equilibrium temperature, they are prepared for final presentation, and this step needs recognition. The downstream activities section includes drying, labeling, date and batch coding, and automated case packing. Every workflow unit directly impacts quality control and, more importantly, traceability, which are the pillars of any high-quality, sustainable packaged workflow.

For example, labeling systems are automated, and servo control guarantees that every label is aligned, even as the speed of production increases. The coding systems imprint the relevant batch and expiration date for accountability and traceability. Then, automated case packing packs bottles or cans for shipment and controls the risk of manual packing.

This completes the hot fill line: the combination of machinery, automation, and clever configurations that keeps the product and brand reputation untainted. The right filling process is not about speed, but the safety and consistency of the product. At the end of the process, a product is presented to a consumer that can be trusted.

Hot Filling vs. Cold Filling vs. Aseptic Filling: Which is Better for Your Products?

Choosing the appropriate filling process for liquid food products and beverages is crucial for upholding product quality, safety, and shelf life. Each technique—hot filling, cold filling, and aseptic filling—has unique strengths and weaknesses to consider for your product and targets.

In this section, we will evaluate the advantages, disadvantages, and best use case scenarios for these three approaches. By the end, we will offer the best option for your liquid food products or beverages in light of the information presented.

| Feature | Hot Filling | Cold Filling | Aseptic Filling |

| Temperature | 85°C – 95°C | Room temperature | Typically under 25°C |

| Heating Method | Liquid is heated before filling to kill microorganisms. | No heating process. Relies on preservatives. | Liquid is sterilized separately, then filled in sterile conditions. |

| Suitable Products | Juices, sauces, non-carbonated drinks, soups | Carbonated beverages (sodas, sparkling drinks) | Sensitive products (dairy, formulas, some juices) |

| Sterilization | Natural sterilization through heat. | Uses preservatives to maintain product safety. | Ultra-clean environment (sterile tanks, machinery, air). |

| Packaging Material | PET bottles, glass containers | PET bottles, glass bottles | Typically, glass or laminated cartons |

| Shelf Life | Longer shelf life due to sterilization | Shorter shelf life, depends on preservatives | Very long shelf life without preservatives |

| Cost | Moderate cost, equipment is affordable. | Lowest initial cost, simple setup. | The highest cost is due to complex machinery and requirements. |

| Complexity | Moderately complex, requires good temperature control and cooling. | Simple, fast, but limited product types. | Very complex, requires controlled sterile environments. |

| Production Speed | Moderate, as it includes heating and cooling. | Very fast, no heating process required. | Slow, due to strict sterilization and setup. |

| Best For | Beverage producers, soups, sauces, and non-carbonated drinks. | Carbonated drinks like sodas, sparkling water. | High-end products like dairy, infant formulas, or juice blends. |

Key Applications: From Juices to Viscous Foods

Hot filling machines are common for the packing of beverages and liquid food items. This technique ensures safety and prolonged shelf life by using high temperatures to sterilize the product, making it excellent for items that require long-term preservation of flavor, texture, and nutritional value.

- Juices & Beverages: For juices, smoothies, and non-carbonated beverages, the hot fill method is ideal. It keeps nutrients and natural flavors intact while destroying harmful microorganisms. There is a claim that PET bottles are the most common packaging type because they resist high temperatures from the product without deforming. This ensures that the product is freshly sealed for several months without the use of preservatives.

- Sauces and Condiments: Hot filling is beneficial for flavor and safety preservation in products like hot sauce, ketchup, and salsa. This technique uses piston fillers, which are technologically advanced for these sauce-type products and sealing in PET or glass bottles for contamination safety.

- Soups and Ready-to-Eat Meals: Hot filling also benefits soups and ready-to-eat meals by removing the need for preservatives while maintaining the product’s quality. This is ideal for convenience stores. There is an advanced technology in piston fillers and weight filling machines for closing sealed which ensures safe consumption of the sealed products.

- Baby Food & Dairy Products: Aseptic filling is not the only option for certain products. Hot filling works just as well for liquid infant formulas, yogurt-based beverages, and other dairy products. A high filling temperature simultaneously destroys bacteria and helps retain vital nutrients for long shelf life and preservation.

- RTD Teas & Coffee: Ready-to-drink (RTD) beverages, including iced tea and coffee, utilize hot filling for the same reason during the filling and packaging stage. Hot filling helps retain the flavor and the nutritional value of the beverage during shelf stability since there is no need for preservatives.

The Real Hot Fill Challenge: Viscous Products & Glass Jars

Most standard hot filling machines work well for low-viscosity (thin) liquids, such as juice and tea. The real engineering problem arises when the product to be hot-filled is a high-viscosity jam, thick sauce, or soup with particulates.

In addition, several high-end food companies provide glass jars packaged products as the industry has developed a preference for glass. This creates additional challenges of:

- Viscous Product Filling: The filler (say, a piston filler) needs to be powerful enough to move the product and accurate enough to the point of no dripping or stringing, while precise fill volumes and the outer packing are also viscous and heavy.

- Glass Jar Specifics: There is a need for careful handling of thermal shock (avoiding cracks) along with the need for a high-performance, precision-torque Capper in order to achieve a perfect vacuum seal for longevity of the shelf life.

To address both the “viscous filling” and “glass jar sealing” problems, the manufacturer needs to have a deep understanding of both mechanical design and precision manufacturing.

This is exactly what Levapack’s engineering team offers. With the in-house CNC machining center (2μm precision), we are able to design and construct high-quality Viscous Liquid Fillers.

We don’t offer just standalone machines. We integrate our high-precision filling with our dependable Capping Technology to provide a complete, fully automated system for hot filling tailored to your needs for glass and plastic jars. We utilize SEW motors for dependable power and sophisticated control via Siemens PLCs to ensure that every function from filling to capping is steady and reliable.

If your product, whether sauce, jam, or soup, is dealing with hot filling, reach out to our engineering team today. We pride ourselves on our ability to simplify intricate process requirements and convert them into effective, dependable, automated production lines.

Your 10-Point Hot Fill Machine Checklist

This buyer’s checklist outlines the basic parameters for vendors and value-determining solutions for your technical and commercial needs for a hot fill machine.

- Product & Container Compatibility: Does the machine fill your specific product and handle all your container variations, both size and type? Has it been tested for container sizes, lengths, and diameters? What about for different product temperatures, viscosity, and particulates?

- Material of Construction: Is the complete product pathway—tank, piping, hoses, and valves—done in 316 stainless steel, or will 304 suffice for high-acid or high salt products, or do all of them need to be 316?

- Changeover Time & Process: What is the maximum guaranteed changeover time (in minutes) to move from one container format to another, and will it need more than 3 or so tools?

- CIP (Clean-in-Place) System: Is it a completely automated relapsing CIP? Check to see specifically how long (time, temperature, flow rate, chemical) for a complete cycle during automated CIP for product safety.

- Filling Technology & Accuracy: What is the filling technology (overflow, piston, or weight filling machine) and what is the guaranteed fill accuracy? How does the accuracy of a value of a product directly cost?

- Total Cost of Ownership (TCO): Assessing Total Cost of Ownership means looking past just the purchase price. Looking at energy consumption (kW/h), cooling tunnel water usage, and annual spending on mandatory spare parts can help to inform purchasing decisions.

- Integration & Footprint: How will this filler fit electronically with my upstream (heater) and downstream (cap, labeler) equipment? What is the cooling tunnel calculation for the overall footprint and the exact footprint overall?

- Quality Control (QC) Features: What onboard QC functions are over the checks? Does it have fill level inspection, cap/seam integration checks, and an automated rejection system?

- After-Sales Support & Warranty: What does the warranty cover? (If it covers 12-16 months, the warranty likely signals confidence). Do they have remote diagnostics 24/7? What about local technicians or dealers?

- Factory Acceptance Test (FAT): What is included in the FAT protocol? The vendor needs to agree to test the machine with your product and containers for an extended run (like 36-48 hours) to demonstrate stability and performance.

Frequently Asked Questions (FAQs) About Hot Filling Machines

- What is the Ideal Temperature for Hot Filling?

Ideal hot fill temperature is about 85°C and 95°C, depending on the product attributes. This takes care of bacteria elimination and ensures the taste and texture of the product are maintained. Some juice filling machines and liquid fillers offer more precise control of the fill temperature for specific products such as hot sauces and stick deodorants.

- How Long Does It Take to Install a Hot Filling Machine?

Depending on the configurations and size, a hot fill line typically will take about a week to a week and a half to set up, test, and calibrate. It is crucial to balance the set parameters to avoid filling level inconsistencies and improper sterilization.

- Can Hot Filling Machines Handle Different Bottle Shapes and Sizes?

Yes, the bottle filling machines of today are very flexible. They can be fitted to suit all sorts of spouts, bottle forms, and sizes, ranging in size between small perfume bottles and huge beverage bottles. This flexibility gives the manufacturers the opportunity to diversify their packaging without committing to several systems.

Conclusion

Hot fill technology is a true staple in the food and beverage industry. This is a result of the technology providing longer shelf life, clean-label products, and reasonable capital investment.

Nonetheless, the success of a hot fill line is not determined by the filling machine alone. It is determined by the total integration of the system, from the precise handling of your unique product to the validation of the final, safe seal.

When choosing a vendor, you are not just purchasing machinery. You are also gaining an engineering partner. If this partner only understands thin liquids in PET bottles, they do not have the background to solve the intricate problems with viscous soups in glass jars. The partner you choose has to be an engineering team that knows the juice, hot sauce, or high-viscosity canned meal chemistry.

Since 2008, Levapack has transitioned with the industry, invested in high-precision CNC manufacturing, and mastered the art of canning and packaging lines for the most demanding applications. You can rest assured as we have well-crafted, integrated solutions, and we have built systems to last.

Reach out to our engineers to discuss your project if you are ready for a proven solution for integrated systems.