Get Your Custom Can Seamer Machine In Levapack To Maximize Your Output

Customizing a Can Seamer Machine aligns the equipment with your unique production needs, potentially leading to improved efficiency, product quality, and cost savings over time.

Initially Coordinating

These Details with Us

Provide us with the specific details below, and we will tailor a can seamer that perfectly matches your needs.

- Materials to Pack

- Machine Type Requirement (Single/Multiple Lines)

- Product Yield Demand

- Plant's Size and Layout

- Special Requirements (e.g., Vacuum Packing)

Choose Brand-Matching

Can Sealer Electrical Parts

Can sealer parts matter. Make informed choices for consistent, smooth operation and optimal efficiency.

- Compatibility with your specific can sealer

- Reduced downtime, improved efficiency

- Enhanced durability for reducing replacement frequency

- Meets industry safety standards

- Upgradable for future demands

Custom The

Seamer Mould

We customize seamer moulds to your can dimensions, Diameter x Height, including Seaming Chuck, Turntable, and Lid Feeder.

Custom The

Seamer Rolls

We have precise solutions for the challenges of customizing the seamer rolls to various packaging materials, such as: tin can, PET can, aluminum can and paper tube.

Customize The Seamer Machine's Size

We tailor the size of your seaming machines to perfectly fit your factory layout and production needs.

Boost Your Sales With Levapack

Can Sealing Machine Factory

Key Features:

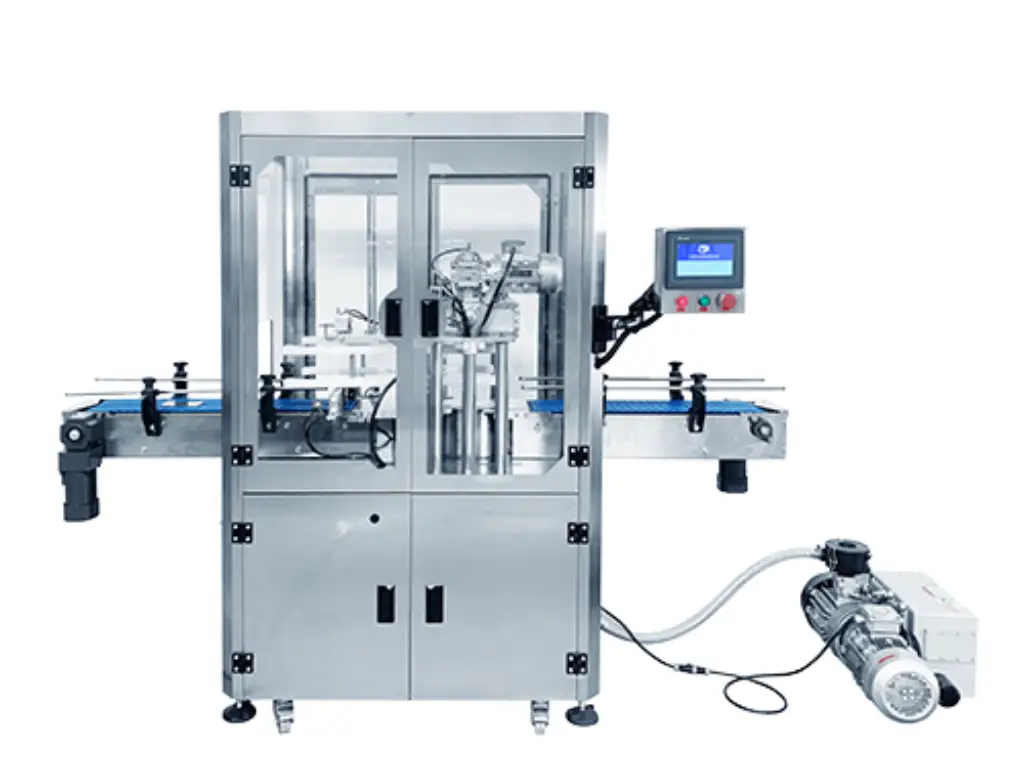

- Model: LPE-NPS35

- Boost Output: Seal up to 40 cans per minute.

- Simple to Use: Siemens touchscreen makes operation a breeze.

- Reliable & Durable: Built with top-quality AIRTAC & DELTA components.

- Versatile: Seals various round containers, from tin to aluminum.

- Freshness Guaranteed: Negative pressure preserves food like meat, seafood, & veggies.

- Retort Ready: Perfect for products needing high-pressure sterilization.

Key Features:

- Model: LPE-FIS100

- Mass Seal: Blast through production with rapid induction technology.

- Custom Fit: Bespoke head adapts to any container size and shape.

- Safe & Reliable: Auto protection ensures smooth operation.

- Non-Stop Flow: Built-in conveyor keeps things moving.

- Leakproof & Fresh: Advanced heat seals lock in quality and freshness.

- Simple to Use: Digital display, clear buttons, and adjustable head for effortless operation.

Key Features:

- Model: LPE-SVC05

- Semi-auto Speed: Faster than manual, flexible control.

- Double Can Power: Two chambers seal twice as fast.

- Can-Do Versatility: Handles all types of round cans.

- Tough & Trusty: Built to last with Cr12 steel and SUS304 hygiene.

- Freshness First: Vacuum & nitrogen lock in quality, extend shelf life.

Key Features:

- Model: LPE-SLV20

- Effortless Control: Manual-feel, auto-speed for consistent seals.

- Beginner-Friendly: Single-head design, easy to operate.

- Built to Last: Stainless steel & Cr12 rollers, hygienic & rust-proof.

- No Spills: Stationary cans, protects liquids & fragile goods.

- Budget-Savvy: Reliable sealing at a smart price.

Key Features:

- Model: LPE-FVC10

- Universal: Seals tin, aluminum, plastic, paper – endless possibilities.

- Freshness Locked: Vacuum & nitrogen <3% oxygen for extended shelf life.

- Efficiency Reigns: Closed-chamber, seamless flow, maximized uptime.

- Taste Protected: Nitrogen guards against oxidation, preserves quality.

- Waste Reduced: Less spoilage, more profits.

- Beyond Food: Food, pharma, nutraceuticals, chemicals – it seals all.

Key Features:

- Model: LPE-FHV50E

- Cans galore: Metal, PET, paper – 130mm max diameter.

- Twice the Sealing Power: Four rollers, leak-proof seals, zero waste.

- On-demand speed: Adjusts to your flow, peak or slow.

- Auto champion: Blazing 50 cans/minute, high-volume hero.

- Seafood, food, drinks: Crush demand, seal the deal.

Key Features:

- Model: LPE-NFS20

- Precise and Consistent Sealing: 1 sealing head and 2 seaming rollers for high precision packaging.

- Adjustable Speed: Flexible sealing speed of 15-30 cans per minute.

- Environmental Adaptability: Efficient across temperatures 0-45°C and humidity 35-85%.

- Freshness Preservation: Low oxygen levels (3-5%) to extend nut shelf life.

- Cost-Effective: Low air consumption of about 80L/min for reduced operational expenses.

Can Sealing Solutions for Every Industry

| Machine Types | Applicable Industries | Scenarios | Benefits |

|---|---|---|---|

| Negative Pressure Vacuum Tin Can Sealing Machine | Food & Beverage, Pet Food, Pharmaceuticals | Canning pre-cooked meals, soups, sauces, pet food pouches | Extends shelf life, airtight seals, retort-ready |

| Aluminum Foil Induction Sealing Machine for Screw Caps | Pharmaceuticals, Cosmetics, Food & Beverage, Nutraceuticals | Sealing vials, bottles, jars, food containers | Tamper-evident, high-speed, customizable head |

| Semi-Auto Vacuum & Gas Nitrogen Flushing Round Can Seamer | Craft Breweries, Coffee Roasters, Food Processors | Sealing craft beers, coffee beans, sauces, dips | Minimizes oxygen contact, maintains product quality, small-medium production |

| Semi-Auto Canning Seamer | Small Businesses, Home Businesses, Hobbyists | Canning jams, preserves, pickles, craft beers, kombucha, sauces | Affordable, manual control, diverse can sizes |

| Fully Auto Nitrogen Filling Vacuum Can Sealer Machine | Large Food Processors, Meat Packaging Plants, Seafood Distributors | High-volume canning of meat, seafood, vegetables, soups, ready-to-eat meals | Efficient, nitrogen-filled, high-demand environments |

| High Volume Fully Auto Round Can Sealing Machine | Large Beverage Companies, Canneries, Food Manufacturing Plants | High-speed sealing of aluminum cans for beverages, seafood, fruits, vegetables, prepared meals | Unmatched production capacity, leak-proof seals, diverse can types |

| Nitrogen Gas Can Sealing Machine for Nuts Packaging | Food Processing, Dried Nuts Retail, Health Foods, Supermarket Chains | Packaging of nuts and dried fruits, organic food packaging, specialty retail packaging | Extends shelf life of nuts, ensures consistent packaging quality, reduces operational costs |

Why Choose Levapack

As Your Can Seamer Manufacturer?

Partnering with experienced can seaming machine manufacturers like Levapack is crucial. We offer tailored solutions that cater to both production efficiency and the unique properties of diverse materials.

High-Quality Materials and Top-Brand Components

Levapack’s machines, ideal for food and beverage industries, feature 2mm thick #304 or #316 stainless steel for durability and hygiene. We collaborate with top brands like Siemens, SEW, SMC, and Schneider for vital components, ensuring high performance and longevity.

Our can seaming machines boast HDPE turntables, easy to clean and durable, with an auto-protection setting in fully automatic models.

Efficient Production Capabilities

Levapack operates in a 4,000 square meter modern workshop. Our can seaming machines include fully automatic can seamer, capable of producing 30 units in 7 days, and semi-automatic models with a production rate of 50 units per day.

Quality is ensured through rigorous testing. We utilize seam tester to precisely measure the fold rate, vacuum testers to detect any leaks, and residual oxygen analyzers to ensure optimal oxygen levels in packaging. This comprehensive approach guarantees the high performance and reliability of our can seamers.

Advanced Technology Integration

Levapack’s automatic canning machines use servomotors for precision and quick malposition correction, reducing maintenance and preventing failures.

Integrated overload devices stop operations during breakdowns to protect electrical components, extending machine life and safety features like emergency stops and guards enhance operator safety and machine durability.

Thorough Testing and Detailed Cleaning

Levapack’s can seamers are expertly hand-assembled by engineers with 14 years of experience. Each machine is rigorously tested with over 100 continuous runs, followed by a comprehensive aging test that includes a 36-hour idle run and bi-hourly checks of real function operation and documented in video reports for our customers.

After successful testing, we meticulously clean each can seamer which include polishes weld points, uses specialized stainless steel cleaners, and applies anti-rust oil and comprehensive protective films for ultimate preservation.

Secure and Safe Packaging

Levapack can seamer are packed in sturdy wooden crates with packing foam to protect the touch screen. The machine is also labeled with detailed instructions for assembly. Steel wires and straps are used to secure the machine in the crate to prevent it from moving around. The machine is also wrapped in plastic film to protect it from scratches.

Full-Service Can Sealer Support

As a sealing machine supplier, we don’t just offer canning seamer, we offer complete peace of mind. Our comprehensive support includes troubleshooting to minimize downtime, training to empower your team, and maintenance assistance to keep your lines running smoothly.

We understand the importance of maintaining peak performance, so we provide essential spare parts and components for easy replacements whenever needed. And because we stand behind our machines, we offer a 16-month warranty that covers not only repairs but also the free replacement of any damaged parts, minimizing risks and guaranteeing uninterrupted performance.

Scale Your Sales with

Proven Packaging Machines

More Detailed

Of Can Seaming Machine In Levapack

Can Sealer Machine Parts and Function

The Three-Stage Process Of Can Sealing Machine

Compression

Positioning and Grip: The can is firmly secured against the seamer chuck, ensuring proper alignment. The chuck also holds the lid in place.

Vacuum and Flush (Optional): For vacuum sealers, air is first sucked out of the can and replaced with inert nitrogen gas to prevent spoilage.

Double Seaming: The can and lid undergo a two-step folding process called "double seaming." This creates a strong, airtight seal by interlocking the lid's curl with the can body's flange using special rollers.

First Roller Operation

The first roller operation stage is the most critical one as it affects the seam’s integrity. A successful first roller operation stage ensures that tightness issues (or wrinkles) and leaks are avoided. In this stage, the first seamer roller comes in to fold the lid’s curl towards the can’s flange. The first roller stage must not be too tight or too loose as this cannot be corrected later.

First, the lid’s curl (which is wider than the can’s flange) is pushed by the first roller and turns around first. Next, the can’s flange follows while the roller advances closer to the chuck. Lastly, the lid interlocks with the body of the can but is not sealed hermetically yet.

Second Roller Operation

After the initial joining in the first roller operation, the lid and can body are loosely connected with "hooks." The integrity of these hooks is monitored for seam quality.

The second roller operation tightens this connection, compressing the hooks for a firm seal. A sealing compound is then applied to ensure a hermetic seal, protecting the can's contents from leaks and contamination.

The double seam's final shape depends on the rollers' design, alignment, and relative positions, as well as the lifter's height and pressure. This process is also detailed in a guide with an accompanying video, focusing on sealing aluminum cans.