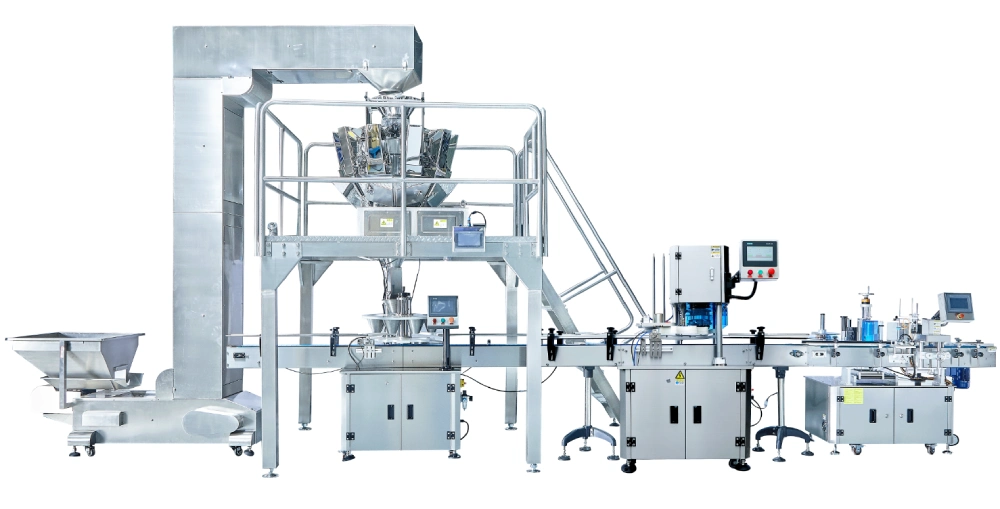

Coffee Bean Packaging Machine: Complete Can & Pouch Solutions in One Line

Our coffee bean packaging line addresses the whole procedure of quantitative filling, can sealing, vacuum sealing, nitrogen flushing, screw capping, labeling and laser code. The system can be customised according to the needs of the particular customers and is also compatible with different packaging formats like cans, jars, and stand-up pouches.

Key Features of Our Coffee Bean Packaging Machines

The coffee bean packaging machines that are developed by Levapack are designed to be able to live up to the expectations of modern coffee producers. Whether it is accuracy in weighing, maintaining freshness, and flexible packaging, all these elements are designed to ensure the quality of your products, efficiency, and brand development. Discover the main peculiarities of our solutions in the coffee industry.

High-Precision Weighing & Filling

The high-speed multihead weighers or precision linear weigher systems, customized to granular products, such as whole coffee beans, are used in our coffee bean packaging machine. The dosing accuracy of these systems is within +/-1g, which greatly reduces wastage of materials and maintains the weight of each package. This guarantees the quality of your product and builds a higher level of trust among customers.

Robust and Durable Structure

Built from food-grade thickened stainless steel and equipped with heavy-duty components—such as industrial bearings rated for 5+ years of 48-hour continuous operation—our machines are engineered to withstand the demands of large-scale coffee production. Backed by 15+ years of mechanical design experience and real-world 48-hour non-stop testing (video available), they are ideal for reliable, long-term use in high-output packaging lines.

Freshness-Locking System

Our state-of-the-art sealing system maintains the complex aroma and flavour of the roasted coffee beans. Optional nitrogen flushing and vacuum sealing systems minimise remaining oxygen to less than 3 percent, essentially preserving freshness and greatly increasing product shelf life. Suitable for high-quality or export coffee bean products.

Versatile Packaging Format Compatibility

Levapack coffee bean packaging machines have the opportunity to work with many types of packaging: metal cans, PET jars, glass bottles, and a variety of premade pouches, e.g., zipper pouches, stand-up bags. The system is easily customizable to suit various container sizes and materials, and can be changed to suit changing market demands and branding options.

Easy Operation & Maintenance

The coffee bean packing machine is designed to be efficient and has an easy-to-use PLC control system that uses a multi-language touchscreen. The hygienic open-frame construction is easily disassembled in a short period of time and fully cleaned, to preserve high food-grade standards of sanitation with little downtime.

Comprehensive Operational Safety

The coffee bean packaging machine has intelligent overload protection, emergency stop, guards, and other safety features that make it work with high standards of safety and enhance safety to a new dimension. These measures are satisfactory as far as the full protection of machine employees is concerned, and this makes the production process free of worries.

Watch Our Coffee Bean Packaging Machines in Action

Whether it is flexible pouch filling or a full canning line, our equipment is designed to package coffee beans with the greatest amount of accuracy and efficiency. See them at work and find out how they will make your packaging process efficient.

Coffee Bean Bag Packaging Machine Videos

- Supports various pouch types: stand-up, zipper, flat pouch

- Adjustable fill weights & bag sizes for different bean types

- Optional nitrogen flushing to preserve bean freshness

- Filling speed: up to 60 bags/min (varies by pouch size)

Coffee Bean Can Packaging Machine Videos

- Full-line integration: filling → vacuum + nitrogen → sealing → labeling

- Compatible with tin cans, PET jars, and glass containers

- Residual oxygen <3% with nitrogen flushing system

- Filling speed: up to 60 cans/min (depending on can size & configuration)

Why Select Levapack as Your Coffee Bean Packaging Machines Manufacturer?

Levapack, one of the leading packaging machinery manufacturers, is committed to engineering flawless machinery that not only meets but also exceeds industry standards, aiming to significantly boost your production with exceptional efficiency and reliability. Centered on innovation and customer satisfaction, Levapack endeavors to enhance your operations, ensuring that each packaging machine we produce maximizes your output and streamlines your processes.

Premium components from renowned brands like Siemens, SEW, SMC, and Schneider ensure precise control, enhanced durability, and reduced maintenance needs, setting high standards for machinery reliability and performance.

Every canning machine is subjected to rigorous quality control, including 100+ continuous runs, 48-hour no-load, and 36-hour aging tests, overseen by engineers with over 15 years of experience, ensuring high performance.

A 4,000 square meter workshop and stock of over 80 units monthly ensure prompt availability. Advanced CNC technology enhances the efficiency and standards of canning machine for various production scales.

Offers extensive help, from troubleshooting to training and maintenance, plus clear setup instructions and optional on-site training for seamless operation.

Each canning machine comes with a 16-month warranty, covering free repairs and part replacements, ensuring production line stability with 24/7 customer service.

Prioritizing high-quality materials and advanced design, competitive pricing is maintained for cost-effective canning solutions, ensuring superior value within a reasonable budget.

Work With Levapack in 6 Clear Steps

From first contact to after-sales service, we provide a smooth, transparent, and professional process to bring your coffee bean packaging solution to life.

Professional Consultation

Your business starts with a 1-on-1 consultation where we get to know your packaging requirements, production environment, and objectives.

Solution Customization

Our engineers offer a tailor-made packaging solution, including layout recommendations anda clear quotation.

Order Confirmation

We are then underway once the proposal is accepted and the down payment is received. In case of need, sample testing is organized.

Lean Production

Your machines are made with perfection and are made using superior parts. We provide visual reports at all major milestones of the production.

Rigorous Testing

The performance and durability of the machines are strictly tested. On-site or remote acceptance is accepted, and video/report support is provided in full.

Global Delivery & Support

Post delivery, we offer installation, training, a 16-month warranty, and lifelong technical support no matter where you are.

FAQs about Coffee Bean Packaging Machines

Our machines can be used with whole roasted coffee beans, green coffee beans, and flavored coffee beans. Depending on the size, flowability, and desired speed, you can select different filling systems: multihead weigher, linear weigher, or volume cup.

No. Our filling systems are gentle and use gravity feed and vibration-assisted weighers, which reduce the height of the drop and the mechanical stress, so your beans are still in their original shape and quality.

Nitrogen flushing removes oxygen in the container and limits oxidation, retaining aroma and freshness. Our systems are able to attain residual oxygen levels of less than 3% which is a considerable shelf life extension.

Levapack is a company that deals with compact, modular coffee bean packaging solutions that suit growing brands. Our cofffee bean packaging machines are simple to use, do not need much floor space, and can be used in different packaging formats, making them flexible to produce without much initial investment.

Yes. We provide customized packaging services for whole beans, ground coffee, and even flavored ones. Our crew can adapt the filling and closing systems to the specifications of your product and packaging objectives, regardless of whether you use cans, jars, or pouches.

Yes. Levapack machines are made of food-grade stainless steel 304 or 316, according to your product and hygiene requirements. It is designed to be easily cleaned, and tool-free disassembly of contact parts can be done to guarantee food safety and minimize downtimes.

The most common defects are uneven fill weight, crushed beans, inadequate seals, or loss of aroma. These can be solved by selecting the appropriate filling method (multihead vs. cup), incorporation of nitrogen flushing, and the quality of the material used.

The coffee bean packaging machine price varies depending on the packaging type (can or pouch), automation level, filling system (multihead weigher, cup filler, etc.), and output speed. For example, semi-auto models may start around a few thousand dollars, while full production lines can range from $20,000 to over $100,000. Levapack offers tailored quotes based on your production needs.