A Guide to Double Seam: Mechanics, Quality, and Equipment Selection

목차

What Is a Double Seam in Metal Packaging?

A double seam is a very precise mechanical joint that is created by interlocking the edges of a body of the can and a lid (end) during the seaming process. In contrast to heat-sealing in plastic containers or friction-fit of a snap cap, the double seam is based on the irreversible deformation of metal layers to form a physical barrier.

Core Components and Basic Terminology

One needs to speak seam geometry to control an automated seamer line. Each aspect of a double seam narrates the calibration of the machine and the performance of the material.

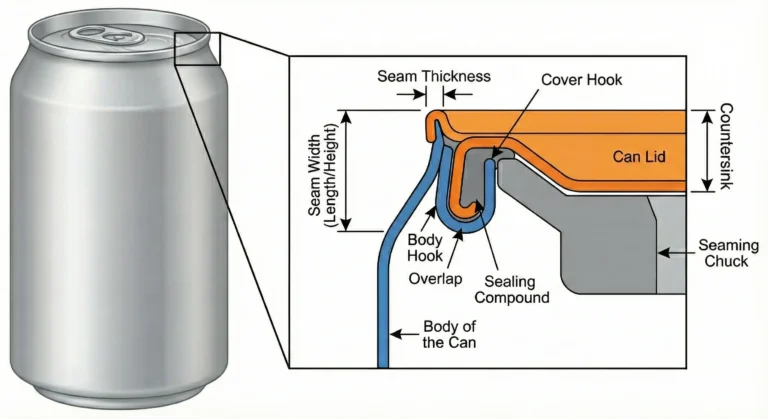

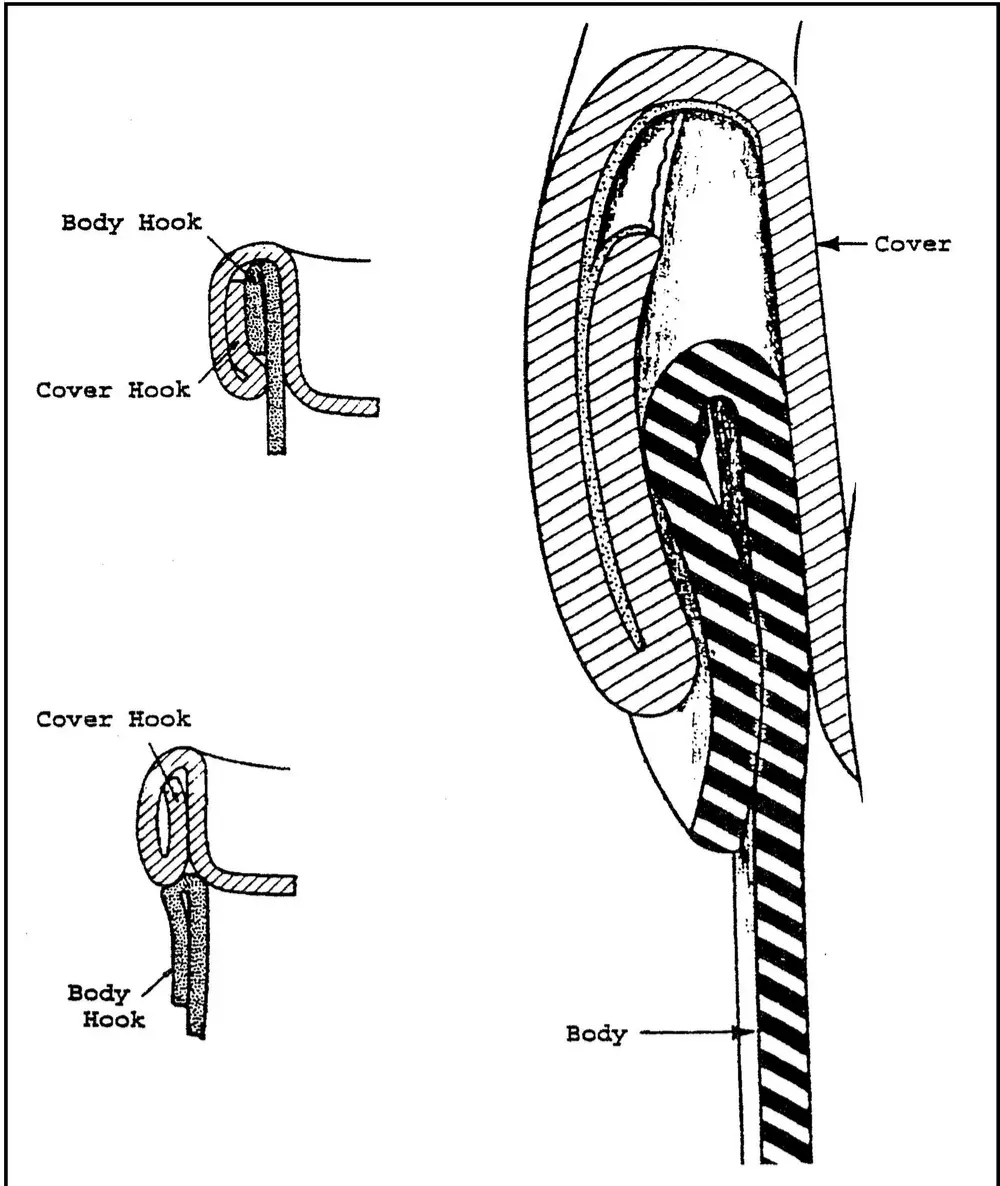

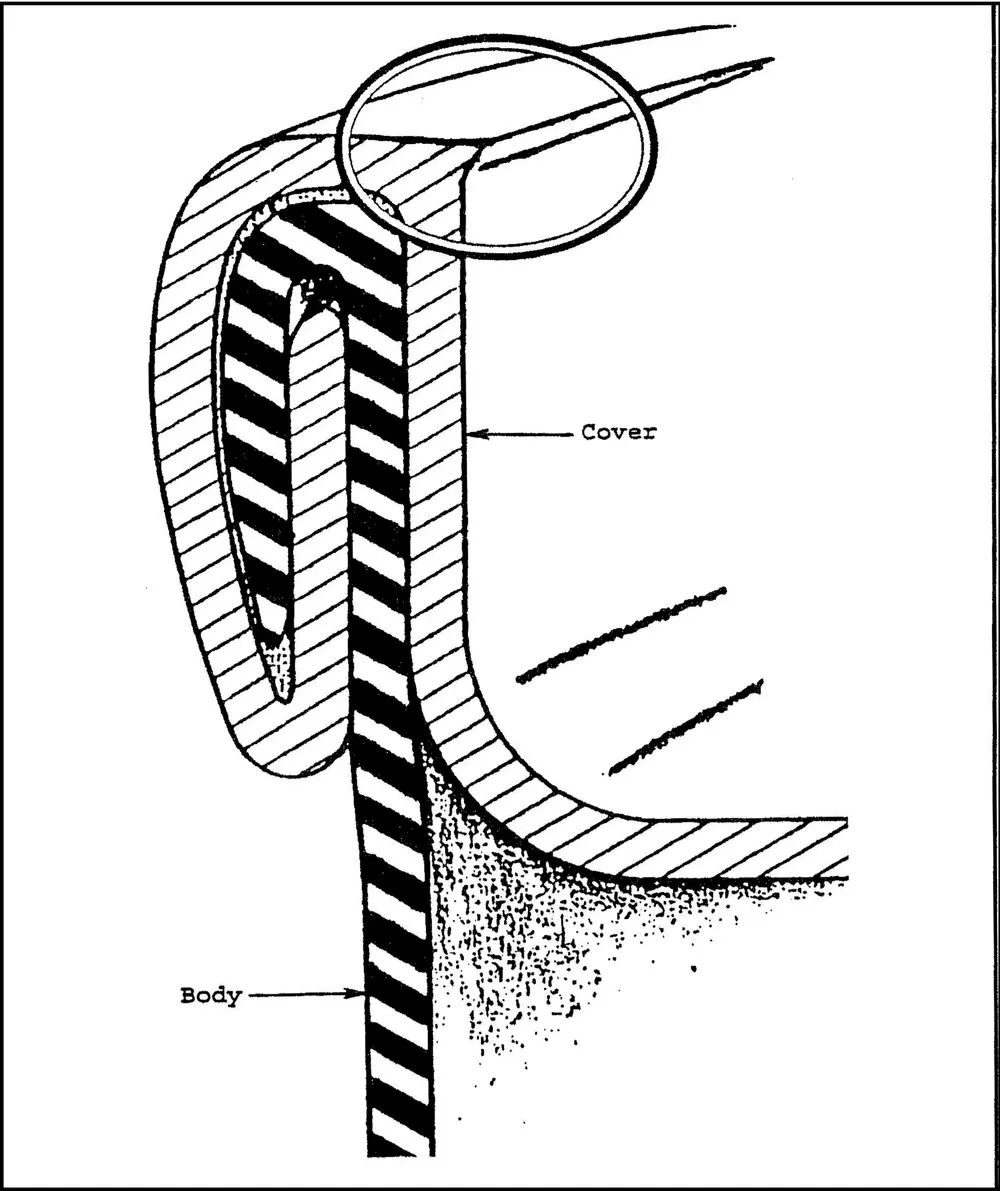

Body Hook: This is the part of the body of the can flange that is folded downwards in the seaming process. It should be a sufficiently long body hook to give overlap, but not too long as to lead to structural buckling.

Cover Hook (End Hook): This is the part of the can lid (the “curl”) that is folded up and folded behind the body hook. A long cover hook provides a deeper reach into the fold, serving as the internal seal.

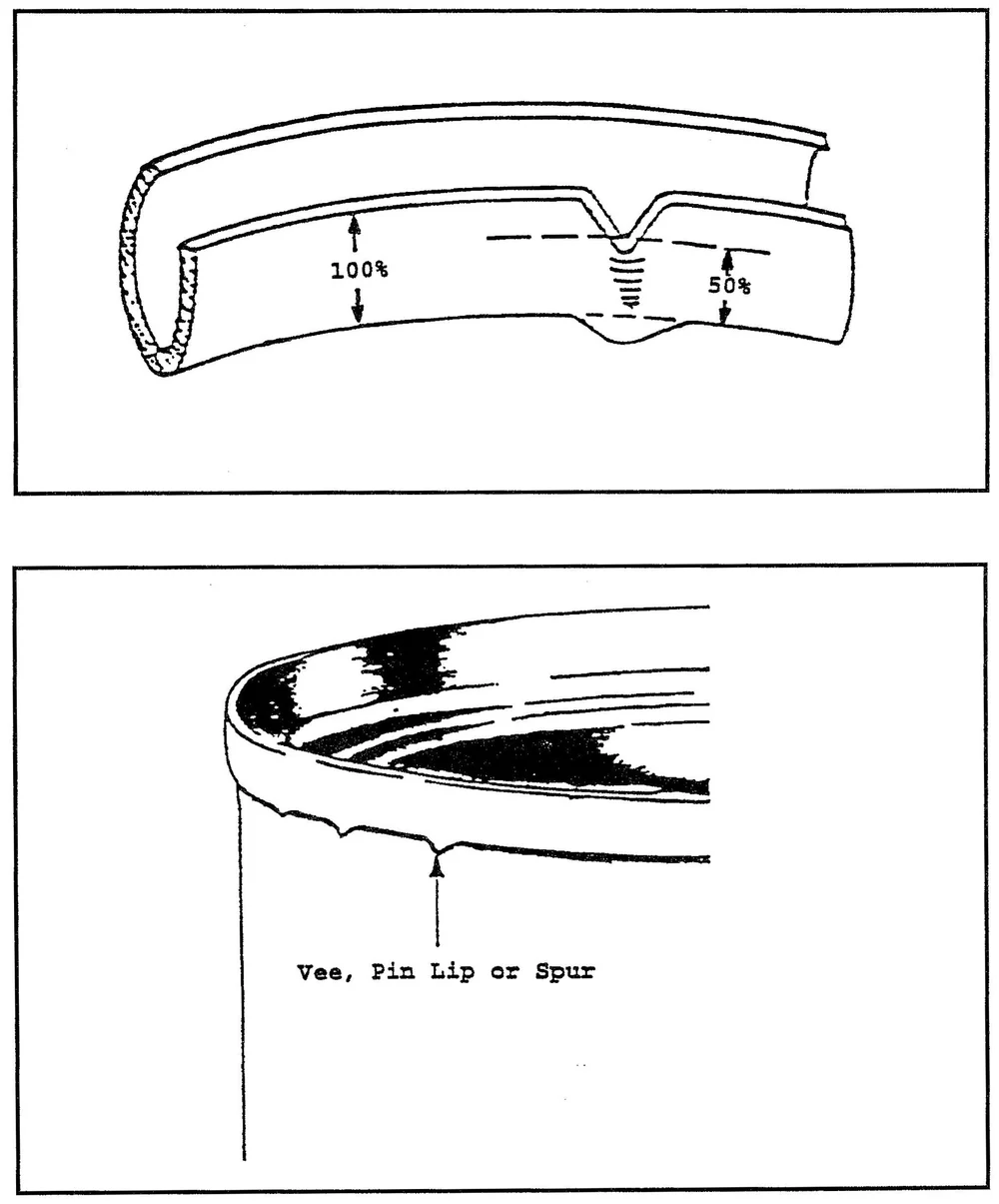

Overlap: This is probably the most significant measure in seam analysis. The physical distance at which the cover hook and the body hook interlock is known as the physical distance. The seam lacks structural integrity without adequate overlap.

Seam Thickness: This is the overall width of the finished double seam, which is the width of all five layers of metal (three layers of the lid and two layers of the body). The excessive thickness is usually a sign of a loose second-operation roll.

Seam Width (Length/Height): This is the largest dimension of the seam in the direction of the vertical axis of the can. Variations in width may indicate roll alignment problems or wear of the chuck.

Sealing Compound: This is a special, tough coating, typically a synthetic rubber or polymer, that is applied to the curl of the can end prior to reaching the seamer. Under the high pressure of the seaming operation, this compound is forced into the microscopic voids between the metal hooks under the high pressure of the second operation, and provides a gas-tight closure.

How the Double Seam Is Formed

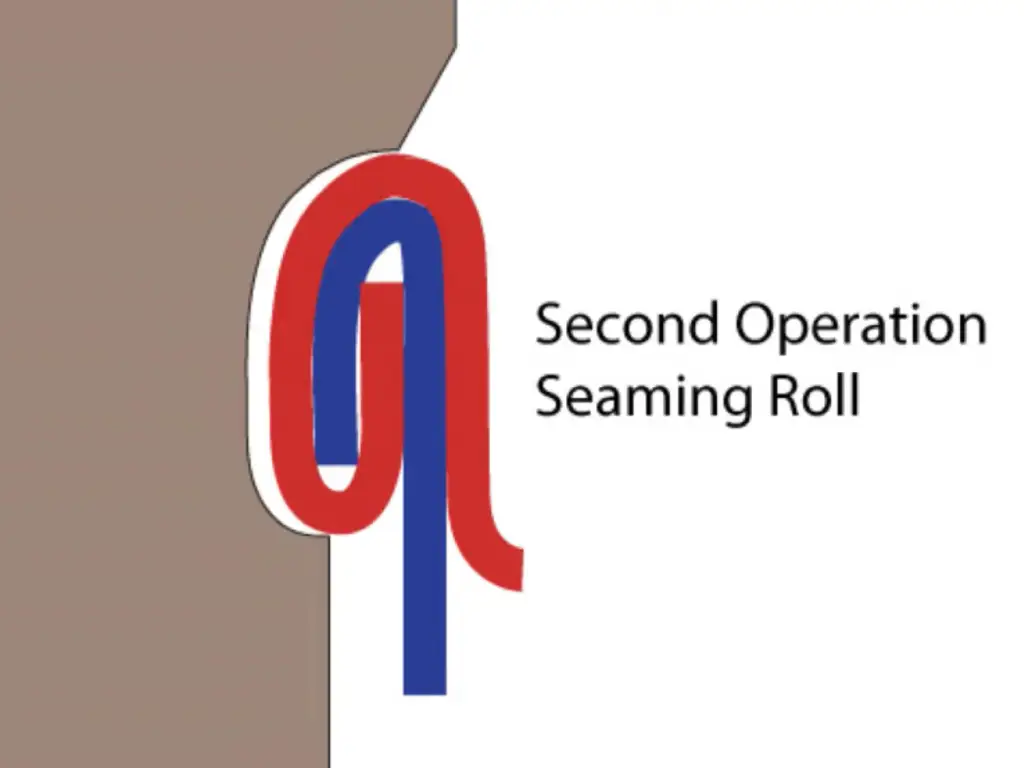

- The Second Operation: Final Compression

Key Benefits of Double Seaming Technology

- Preservation of Product Integrity: Since the process of double seaming is cold (no heat is required to bond the lid), it eliminates the possibility of flavor loss during the sealing process due to heat. This is especially significant in high-end drinks and nutrients that are sensitive.

- 운영 처리량: Rotary seaming machines of modern type can handle more than 1,500 cans in a minute. This scalability is unparalleled with most other sealing technologies and thus it is the most cost effective solution to mass production.

- Verified Security: The double seam is a mechanical joint that is one of the most researched in engineering. Its failure modes are well known and standardized inspection procedures enable manufacturers to demonstrate the safety of their products with mathematical confidence.

Common Double Seam Defects and Their Impacts

- 거짓 솔기: This is a serious failure in which the cover hook and the body hook do not interlock. They are merely forced together. On the surface, the seam might appear normal, but it has zero structural integrity and will leak under the most minimal pressure.

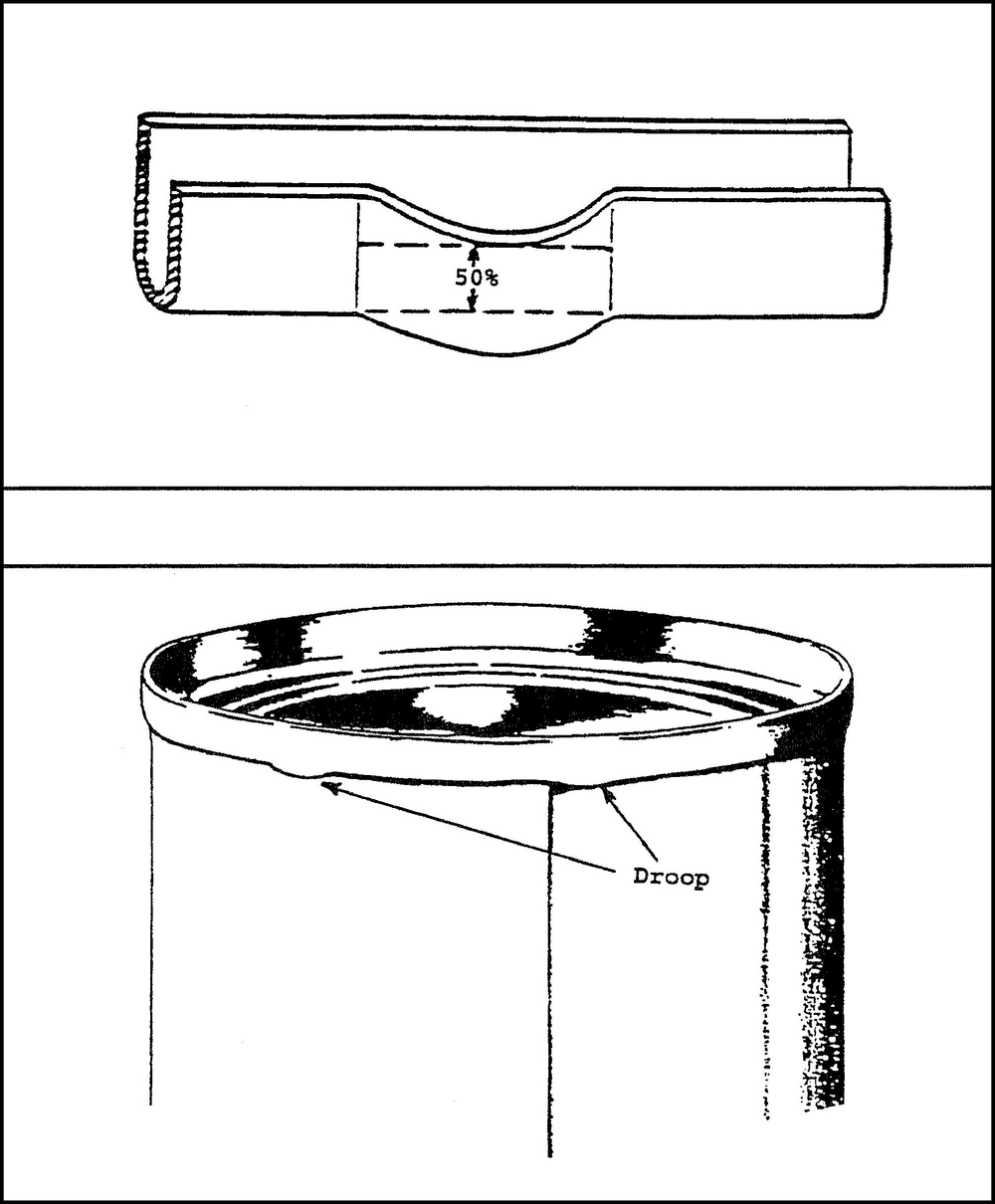

- Droop: A droop is a localized smoothness or projection at the bottom of the double seam. It normally happens when a part of the cover hook slips and is not tucked. This forms a point of possible bacterial intrusion.

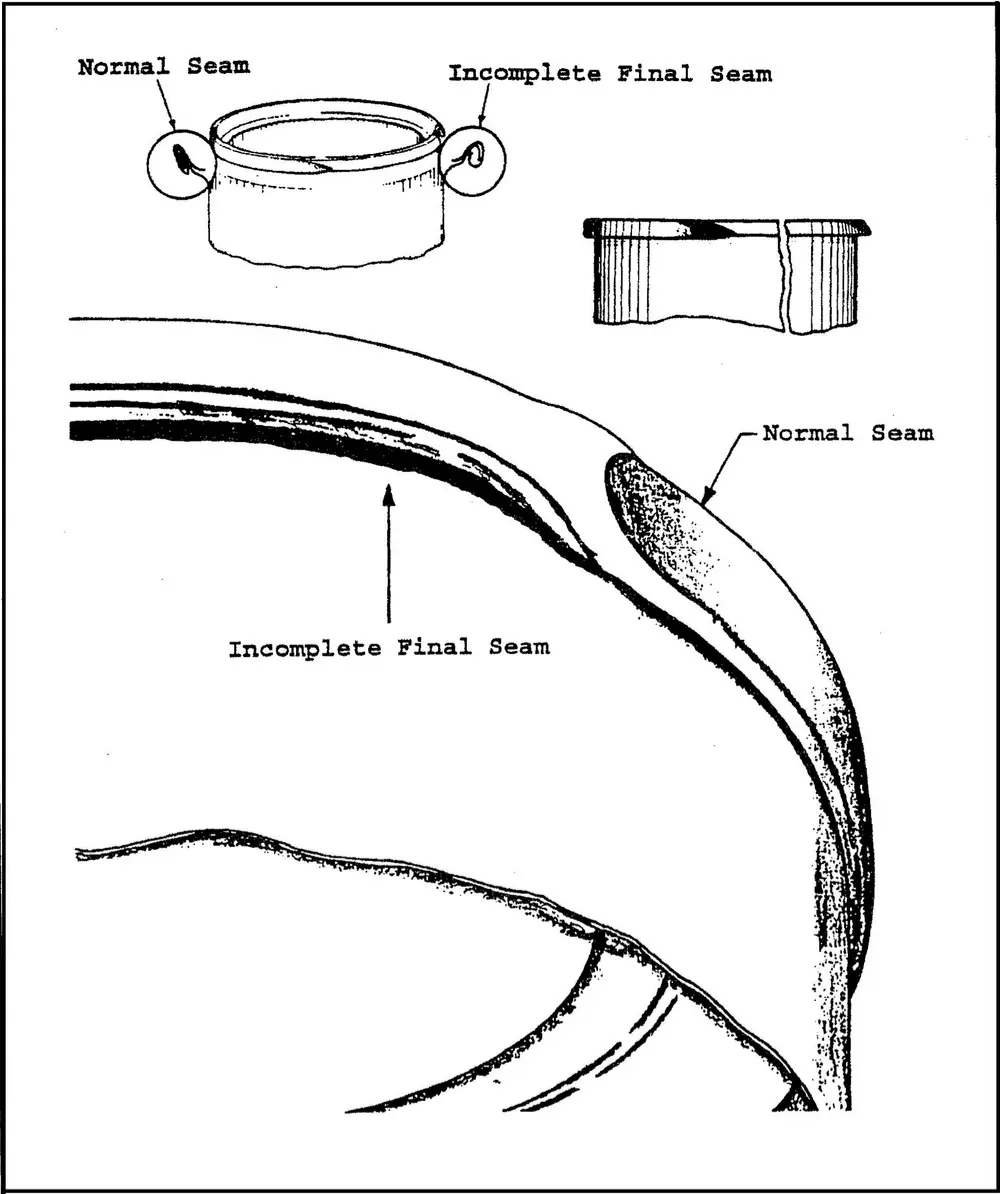

- Vee (Jump Over): These are small V-shaped protrusions at the bottom of the seam. They usually take place close to the side-seam of a three-piece can. They show that the seaming rolls could not sustain the same pressure when passing over the heavier metal of the side-seam.

- Deadhead (Skidding): When the seaming chuck slips on the can lid in the seaming process, it is called a deadhead. The seam is not completely shaped as the can ceased to rotate at the right speed. This can be due to lack of lifter pressure or a damaged chuck.

- Cutover (Sharp Seam): This is a sharp edge on the top of the seam, typically on the inside of the chuck wall. This sharp edge shows that the metal has been squeezed excessively between the roll and the chuck. Cutovers may cause fractured metal and instant seal failure.

Critical Factors for Ensuring Seam Integrity

Mechanical Setup and Material Specifications

- Roll and Chuck Geometry: The seaming roll profiles should be checked to ensure that they are not worn out. The roll profile will be eroded over time as a result of metal-on-metal contact, resulting in loose seams. Most of the current facilities are lined with titanium nitride coated rolls or ceramic to increase their life span.

- Lifter Plate Pressure: This is the force that causes the can body to be pushed into the chuck. It must be balanced. When it is too low, the can will skid (deadhead). When it is excessive, the body of the can will be buckled by the vertical load.

- 재료 일관성: The hardness and thickness of the metal should be uniform. When the metal end is harder than the specification, it will not yield to the rolling force resulting in shallow hooks and inadequate overlap. A frequent cause of double seam defects is changing to a cheaper metal lid without recalibration of the seamer.

Process Parameters and Production Environment

- Overlap Management: The major indicator of safety is Overlap. It is determined by the size of the body and cover hooks. Technical standards normally demand a minimum of 55 percent overlap to be regarded as secure.

- Product Contamination: In case food or liquid spills on the flange prior to seaming, it may be trapped in the joint. This trap does not allow the metal to interlock and forms a leakage route. This is particularly prevalent in fast filling lines where liquids are likely to splash.

- Headspace and 진공: During hot-fill processes, the can undergoes a slight change in its size due to changes in temperature. The seamer should be adjusted to take into consideration the temperature of the metal during the time of sealing to maintain the compression constant.

Three-Level Inspection Checklist for Seam Quality

Level 1: Visual Inspection

- Scratches or scuffing on the seam surface.

- Localized distortions (droops or vees).

- Acute edges on the top of the chuck wall (cutovers).

- Signs of “skidding” where the chuck has ground against the lid. Although visual inspection cannot be used to establish that a seam is good, it can easily be used to establish that a seam is bad, and the production can be stopped immediately.

Level 2: External Measurement

Level 3: Teardown/Destructive Testing

Double Seaming vs. Other Sealing Technologies

| 기술 | Mechanism | Primary Materials | Key Disadvantage |

|---|---|---|---|

| 더블 솔기 | Mechanical Interlock | Tin, Aluminum, PET | Requires precise mechanical calibration. |

| 열 밀봉 | Thermal Fusion | Plastic containers, Laminates | Susceptible to "burn-through" or weak bonds. |

| 인덕션 씰링 | Electromagnetic Heating | Foil liners on Plastic/Glass | Only works with non-metal containers. |

| 초음파 밀봉 | Molecular Vibration | Thermoplastics, Composites | High equipment cost; limited to specific materials. |

Choosing the Right Can Seaming Equipment

- Production Scale and Speed: Adjust the Cans Per Minute (CPM) rating of the machine to your filling line. An imbalance in this case forms a bottleneck in operations. Rotary seamers with multiple heads are the only possible solution to high-speed lines (more than 200 CPM) to guarantee the same dwell time on every can.

- Container Versatility: SKU flexibility is a competitive edge in the current market. Is the machine able to work with various diameters and heights? Find designs with Quick Changeover so that your team can change chucks and rolls within less than 30 minutes.

- Hygienic Engineering: In the case of food and beverage, the machine should be Washdown Rated. This implies stainless steel construction (304 or 316) and a design that does not have any dead spots where bacteria or mold may develop.

- 정밀도 엔지니어링: Research the manufacturing tolerances of the seamer itself. Machines made using CNC-machined parts and high quality bearings are more repeatable, i.e. the 1,000,000th can will have the same quality seam as the first.

- Intelligence and Integration: Does the machine have the sensors of No Can, No Cover or Jam Detection? Is it able to export data to the ERP system of your factory? The learning curve of new operators has been greatly reduced with modern PLC-controlled seamers that have touch-screen interfaces.