Introduzione

Nel settore della produzione alimentare, la sicurezza del prodotto e la durata di conservazione rimangono gli obiettivi più importanti. Il principale avversario in questo lavoro è l'attività microbica, che provoca il deterioramento ed è pericolosa per la salute dei consumatori. Il trattamento termico è stata la misura di controllo più comune e coerente nel controllo microbico sin dalla sua invenzione da parte del chimico francese Louis Pasteur nel XIX secolo. In questo campo esistono due processi principali, la pastorizzazione e la sterilizzazione, che sono diversi ma possono essere facilmente confusi.

La scelta dell'approccio al trattamento termico non è casuale; si tratta di una decisione con conseguenze di vasta portata per la sicurezza, il valore sensoriale e nutrizionale e la fattibilità commerciale di un prodotto. Questa decisione determina la logistica dello stoccaggio e della distribuzione, le esigenze di confezionamento e, infine, l'esperienza del consumatore. Questo articolo offre un'esplorazione metodica della pastorizzazione e della sterilizzazione, partendo dai fondamenti e procedendo a un confronto delle variabili operative e degli impatti dei due processi. Esamineremo come vengono utilizzati nell'industria, forniremo una struttura per aiutare a scegliere il processo e spiegheremo perché le apparecchiature svolgono un ruolo vitale nel garantire risultati di produzione coerenti e sicuri.

Introduzione alla pastorizzazione e alla sterilizzazione

Il deterioramento degli alimenti è il risultato diretto dell'esistenza e della crescita di microrganismi come batteri, lieviti e muffe. Questi organismi, insieme all'attività enzimatica delle fonti alimentari stesse, catalizzano reazioni di decomposizione che modificano la consistenza, il sapore, l'aroma e l'aspetto, rendendo il prodotto inutilizzabile. Inoltre, alcuni microrganismi patogeni, tra cui Clostridium botulinum, Salmonella e Listeria monocytogenes, possono causare malattie potenzialmente gravi se non vengono eliminati con successo.

Il trattamento termico è uno dei principali metodi di conservazione, poiché prevede l'utilizzo di energia termica per distruggere le proteine e gli enzimi vitali di un microrganismo, causandone la morte. Il grado di riduzione microbica dipende dall'intensità del calore impiegato, misurato in base alla temperatura e alla durata. In questo caso, la sterilizzazione e la pastorizzazione prendono direzioni diverse.

Pastorizzazione comporta un trattamento termico relativamente delicato, di solito a temperature inferiori a 100 °C (212 °F). Il suo scopo principale è quello di uccidere i batteri patogeni, o microrganismi che causano malattie, per rendere un prodotto sicuro da consumare. Inoltre, riduce notevolmente il numero di organismi deteriorati, allungando così la durata di conservazione del prodotto a temperature refrigerate. Tuttavia, la pastorizzazione non è destinata a uccidere tutti gli organismi microbici; i batteri resistenti al calore e le spore batteriche sopravvivono al trattamento.

Sterilizzazione, a sua volta, è un trattamento ad alto calore volto a uccidere tutti i microrganismi (sia le cellule vegetative che le spore batteriche molto resistenti). In genere utilizza calore umido, pressione e calore per riscaldare il prodotto a temperature sostanzialmente superiori a 100 o C, circa 121 o C (250 o F), in un recipiente chiuso. Il prodotto risultante è commercialmente sterile, cioè non contiene organismi vitali che potrebbero svilupparsi durante la conservazione a temperature normali, consentendo così una lunga durata a temperatura ambiente.

Pastorizzazione vs. sterilizzazione: Differenze chiave

Tuttavia, i due processi sono diversi nell'uso e i risultati sono significativi anche se entrambi prevedono l'uso del calore. Queste distinzioni sono importanti per qualsiasi produttore di alimenti. Il confronto tra le caratteristiche principali dei due approcci è riportato nel grafico seguente.

| Caratteristica | Pastorizzazione | Sterilizzazione |

| Obiettivo primario | Eliminare gli agenti patogeni; ridurre gli organismi di deterioramento. | Eliminare tutti i microrganismi, comprese le spore. |

| Temperatura tipica | 63°C - 95°C (145°F - 203°F) | > 100°C, in genere 121°C (250°F) |

| Effetto sulle spore | Inefficace; le spore sopravvivono. | Efficace; le spore vengono distrutte. |

| Durata di conservazione risultante | Breve (da giorni a settimane). | Lunga (da mesi a anni). |

| Esigenze di stoccaggio | Richiede la refrigerazione. | Conservazione a temperatura ambiente. |

| Impatto sulla nutrizione | Perdita da minima a moderata di vitamine sensibili al calore. | Perdita più significativa di vitamine sensibili al calore. |

| Impatto sul gusto/sapore | Modifiche minime; conserva bene il profilo sensoriale originale. | Può causare cambiamenti significativi nel colore, nel sapore e nella consistenza. |

Il compromesso sulla qualità: sterilizzazione vs pastorizzazione

La decisione di pastorizzare o sterilizzare influisce in modo diretto e quantificabile sugli attributi sensoriali del prodotto finale, che comprendono il sapore, la consistenza, il colore e l'aroma. L'intensità e la durata del calore applicato sono direttamente proporzionali a questi cambiamenti.

Nei prodotti pastorizzati, i cambiamenti sono piuttosto lievi. Ad esempio, nel latte, una delle forme più diffuse di pastorizzazione, il processo HTST (High-Temperature Short-Time), prevede un tempo estremamente breve di riscaldamento del liquido e un successivo rapido raffreddamento. Questo trasferimento di calore rapido ed elevato è generalmente ottenuto mediante l'uso di scambiatori di calore a piastre o tubolari. Si tratta di un metodo efficace per uccidere gli agenti patogeni mantenendo il gusto fresco e cremoso desiderato dai consumatori. I composti aromatici delicati vengono principalmente preservati e ciò può essere misurato da parametri come i valori po (Unità di Pastorizzazione), un aspetto importante per i prodotti di alta gamma, dove la qualità sensoriale ha un prezzo ancora più alto.

La sterilizzazione esercita un carico termico significativamente più elevato sul prodotto, innescando una cascata di reazioni chimiche e fisiche e influenzando il valore nutrizionale dell'alimento. Un fattore importante è la reazione di Maillard, la reazione chimica tra aminoacidi e zuccheri riducenti. Questa reazione è auspicabile in alcuni prodotti come zuppe, stufati e sughi di carne in scatola, che diventano più ricchi e di colore più intenso, oltre che più complessi e saporiti. In altri prodotti, invece, è dannoso. Ad esempio, l'uso di alte temperature nel latte sterilizzato (latte UHT) produce un caratteristico sapore caramellato e un colore più scuro rispetto alla versione pastorizzata, conseguenza diretta delle reazioni ad alto calore.

Ha anche un impatto significativo sulla consistenza. La sterilizzazione, che comporta temperature e pressioni elevate, può provocare la disintegrazione delle pectine di frutta e verdura e la denaturazione delle proteine delle carni, con il risultato di una consistenza molto più morbida, a volte molliccia. Questo si nota nelle verdure in scatola, come i fagiolini o le carote, che sono ovviamente più morbide rispetto a quelle fresche o surgelate. Questa è una caratteristica tipica e accettabile degli alimenti in scatola, ma non sarebbe una caratteristica auspicabile per un prodotto etichettato come fresco.

Applicazioni comuni nell'industria alimentare

Le applicazioni pratiche dei due processi sono probabilmente il modo migliore per comprendere la differenza teorica tra di essi in tutta l'industria alimentare. La scelta del metodo dipende dalla natura dell'alimento, dal mercato di destinazione e dalla catena di distribuzione.

Pastorizzazione in azione

La pastorizzazione è comune nei prodotti pastorizzati e venduti in una catena di distribuzione refrigerata, che vengono consumati dopo un periodo relativamente breve.

- Prodotti lattiero-caseari: Nella vendita al dettaglio, la maggior parte del latte fresco e un gran numero di altri prodotti lattiero-caseari sono pastorizzati (di solito mediante HTST) come misura di sicurezza senza compromettere il sapore fresco.

- Succhi di frutta: I succhi di frutta di qualità superiore, non provenienti da concentrati, sono solitamente venduti nella sezione refrigerata e sono spesso pastorizzati per bloccare i loro sapori delicati e i loro colori brillanti.

- Birra e vino: La pastorizzazione blocca l'attività dei lieviti e uccide i microrganismi nocivi, stabilizzando il prodotto finale e, in alcuni casi, eliminando la necessità di filtrare.

- Uova liquide: Vengono offerti ai consumatori e ai servizi di ristorazione e sono pastorizzati per eliminare la possibilità di Salmonella.

Sterilizzazione in azione

L'industria conserviera e quella degli alimenti a lunga conservazione si basano sulla sterilizzazione, per cui i prodotti possono essere conservati senza refrigerazione per lunghi periodi di tempo.

- Verdure e frutta in scatola: È la base della maggior parte delle conserve convenzionali. Mais, piselli e pesche vengono inscatolati o messi in barattoli di vetro e sterilizzati per renderli sicuri e stabili nella dispensa.

- Carne e pesce in scatola: Tonno, salmone, pollo e altri tipi di prodotti a base di carne vengono sterilizzati nelle loro scatole, fornendo una fonte di proteine conservabili.

- Pasti pronti e zuppe: Esiste un'ampia varietà di zuppe, chili e piatti pronti sterilizzati in lattine o buste ritrasformabili per renderli convenienti per i consumatori.

- Cibo per animali domestici: I prodotti alimentari umidi e secchi per animali domestici in lattina o in busta sono sterilizzati per garantire una lunga durata di conservazione e la sicurezza microbiologica.

Scegliere il processo giusto per la produzione

La scelta di un processo termico adeguato è una mossa strategica, e pertanto i fattori di prodotto, mercato e logistica devono essere valutati attentamente. Di seguito sono riportate le domande essenziali che un produttore dovrebbe prendere in considerazione quando decide di scegliere:

- Qual è la durata di conservazione prevista?

La sterilizzazione è l'unica alternativa nel caso in cui si desideri che il prodotto abbia una durata di conservazione di diversi mesi o anni durante un periodo specifico. La pastorizzazione sarà appropriata e meno violenta nel caso in cui il prodotto debba essere consumato rapidamente.

- Il vostro canale di distribuzione richiede lo stoccaggio in ambiente?

Considerate l'intera catena di approvvigionamento. Un prodotto commercialmente sterile è necessario nel caso in cui il prodotto debba essere spedito, conservato ed esposto a temperatura ambiente. La logistica determinerà anche il tipo di contenitore da utilizzare, compresi i cartoni refrigerati e le lattine a scaffale.

- Quanto è sensibile il vostro prodotto al calore?

Valutare l'impatto del calore elevato sul sapore, la consistenza e le proprietà nutrizionali del prodotto. Per i prodotti delicati, è preferibile il calore più mite della pastorizzazione. Per i prodotti robusti, i cambiamenti indotti dalla sterilizzazione possono essere accettabili.

- Qual è il pH del cibo?

L'acidità di un prodotto è un parametro decisivo. Le spore del Clostridium botulinum sono naturalmente inibite dagli alimenti ad alta acidità (pH 4,6), come le carni e la maggior parte delle verdure, e pertanto gli alimenti a bassa acidità devono essere sottoposti a processi di sterilizzazione intensivi per essere conservabili.

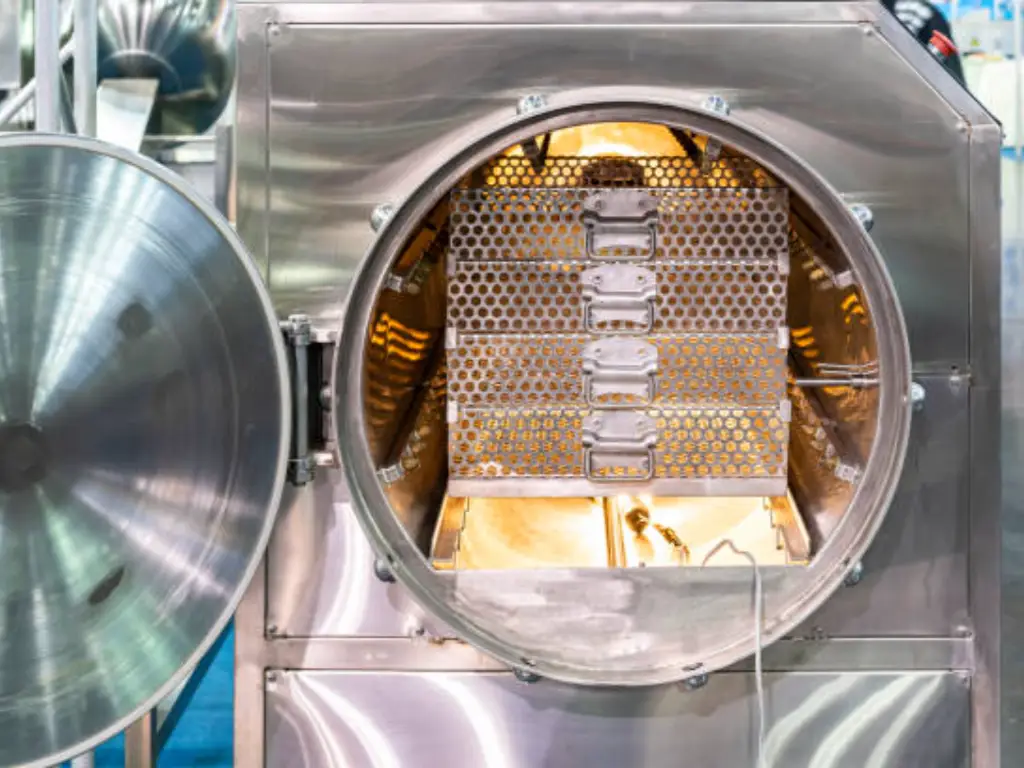

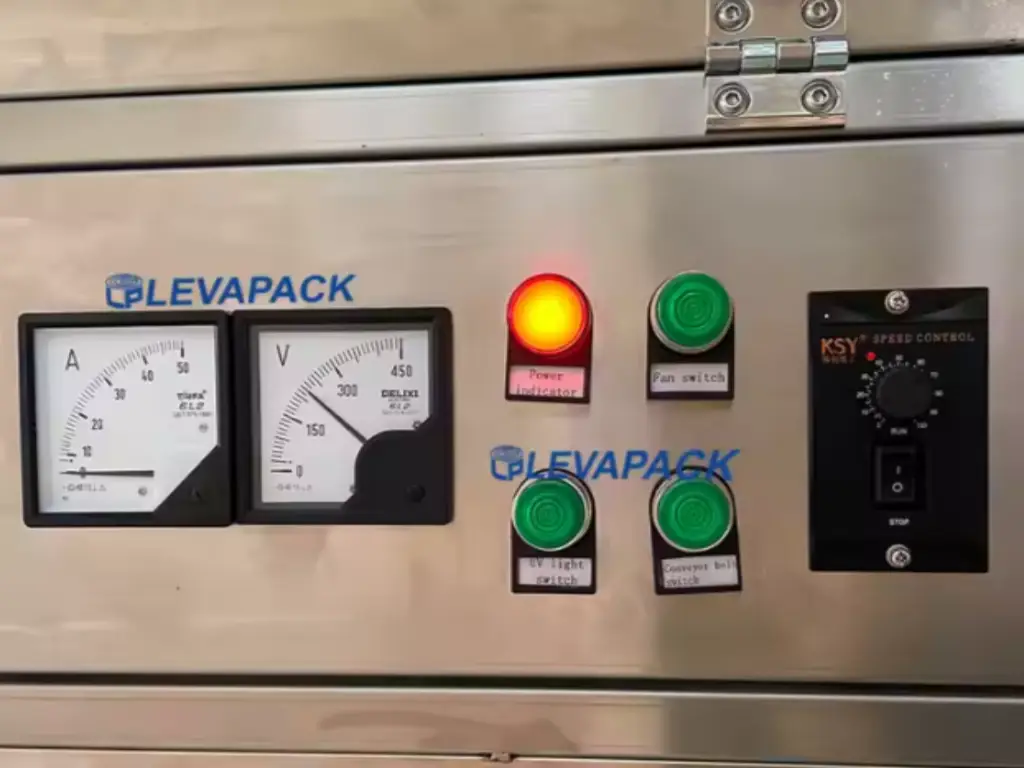

Il ruolo cruciale delle apparecchiature di sterilizzazione commerciale

La sterilizzazione è una scelta strategica. Tuttavia, questa strategia funziona solo se viene attuata correttamente, e tutto dipende dalla qualità e dall'accuratezza delle attrezzature. Uno sterilizzatore commerciale, o storta, non è solo una macchina: è il punto di controllo che garantisce la sicurezza del prodotto e l'integrità del marchio. Se non si riesce a mantenere una temperatura, una pressione o una tempistica costanti, si possono verificare guasti catastrofici, come il deterioramento o addirittura problemi di salute umana.

Ecco perché la collaborazione con un produttore professionista non è negoziabile. In Levapack, abbiamo sviluppato soluzioni di sterilizzazione grazie a una solida ingegneria per fornire soluzioni di sterilizzazione affidabili. Siamo in grado di fornire un approccio completo e interno. I nostri ingegneri qualificati costruiscono e fabbricano ogni Sterilizzatore per lattine in acciaio inossidabile di qualità superiore ed esente da ruggine, per raggiungere i più elevati standard di sicurezza alimentare. Sappiamo che non esistono due linee di produzione uguali: per questo motivo offriamo un elevato grado di personalizzazione, adattando ogni macchina ai vostri esatti tipi di contenitori, ai tassi di produzione e al layout dello stabilimento, per garantire un'integrazione senza problemi e offrire le migliori prestazioni.

Le apparecchiature non devono essere l'anello debole della catena di produzione. Per parlare con il nostro team delle vostre specifiche esigenze di sterilizzazione e progettare una soluzione ad alte prestazioni per guidare economicamente la vostra attività, contattate Levapack oggi stesso e programmate una consulenza.

Oltre il calore: il futuro della conservazione

Sebbene il trattamento termico sia uno standard industriale, la ricerca e lo sviluppo sulla conservazione degli alimenti sono ancora in corso per estenderne i limiti. Diverse tecnologie non termiche si stanno diffondendo in seguito alla richiesta dei consumatori di alimenti dal sapore più fresco, più nutrienti e meno elaborati. Queste tecnologie mirano a distruggere i microrganismi senza o con meno calore, conservando così le caratteristiche originali degli alimenti in modo più efficiente.

- Trattamento ad alta pressione (HPP): In questo processo, i prodotti alimentari sigillati sono esposti a una pressione idrostatica molto elevata (di solito 300-600 MPa) da parte dell'acqua calda come mezzo di trasporto della pressione. Questa pressione altera le attività cellulari di batteri vegetativi, lieviti e muffe senza distruggere i legami covalenti e preserva piccole molecole come vitamine e aromi.

- Campo elettrico pulsato (PEF): Ciò avviene utilizzando brevi impulsi di un campo elettrico ad alta tensione su un alimento liquido tra due elettrodi. Questi impulsi creano dei pori nelle membrane cellulari dei microrganismi, inattivandoli. Si tratta di un meccanismo efficiente in termini di energia e di tempo che viene applicato principalmente a prodotti liquidi come succhi e latte.

Sebbene queste tecnologie offrano vantaggi promettenti, non sono esenti da critiche, come i costi di capitale proibitivi e l'inefficacia contro le spore batteriche. A breve e medio termine, è molto probabile che vengano utilizzate in aggiunta e non in sostituzione dei processi termici convenzionali, soprattutto nella categoria degli alimenti a bassa acidità e conservabili, dove è necessaria l'assoluta letalità della sterilizzazione.

Domande frequenti (FAQ)

Il latte UHT è sterilizzato o pastorizzato?

Il latte ad altissima temperatura (UHT) è un latte commercialmente sterile. Viene sottoposto a un processo di sterilizzazione in cui il latte viene rapidamente riscaldato ad alta temperatura e poi raffreddato. Il processo distrugge tutti i microrganismi, comprese le spore, consentendo al prodotto sigillato di essere conservato a temperatura ambiente per mesi.

Posso sterilizzare gli alimenti a casa in modo efficace?

Per sterilizzare gli alimenti a bassa acidità in casa è necessaria una pentola a pressione. Una pentola a pressione è un'attrezzatura specializzata in grado di raggiungere temperature superiori al punto di ebollizione dell'acqua, necessarie per distruggere le spore del botulismo. Un normale bagno in acqua bollente è sicuro solo per gli alimenti ad alta acidità.

La sterilizzazione distrugge tutti i nutrienti degli alimenti?

No, non uccide tutti i nutrienti. Il processo di sterilizzazione ha un impatto notevole sulle vitamine sensibili al calore, tra cui la vitamina C e alcune vitamine del gruppo B. Ma i macronutrienti (proteine, grassi, carboidrati) e i minerali non vengono intaccati più di tanto. Ma i macronutrienti (proteine, grassi, carboidrati) e i minerali non vengono intaccati più di tanto. Anche i cibi in scatola hanno un valore nutrizionale.

Che cos'è la "sterilità commerciale"?

La sterilità commerciale è lo stato che si ottiene quando il calore viene applicato in misura sufficiente a rendere un alimento privo di microrganismi in grado di moltiplicarsi al suo interno nelle normali condizioni di conservazione e distribuzione non refrigerate. Non è una sterilità completa, ma è un criterio canonico per la conservabilità degli alimenti in scatola.

Perché i cibi acidi a volte richiedono solo pastorizzazione per la conservazione a lungo termine?

L'acidità (pH <4,6) di alimenti come pomodori e sottaceti è letale per lo sviluppo di batteri nocivi come il Clostridium botulinum. Questo batterio non è in grado di crescere e secernere la sua tossina letale in un ambiente ad alta acidità. Pertanto, richiede un livello inferiore di trattamento termico per rendere il prodotto conservabile e buono fino al momento dell'apertura.

Conclusione

La decisione tra pastorizzazione e sterilizzazione non è una mera decisione tecnica, ma piuttosto una decisione strategica alla base della produzione alimentare. La pastorizzazione non distrugge le pregiate qualità sensoriali e nutrizionali di cui i prodotti freschi hanno bisogno, mentre la sterilizzazione elimina quasi del tutto la carica batterica, garantendo la completa sicurezza e la conservabilità a lungo termine necessarie per la distribuzione in grandi volumi nel mercato ambiente. La direzione corretta dipende esclusivamente dalla natura del prodotto, dagli obiettivi di mercato e dalla capacità di distribuzione. Alla fine, in entrambi i casi, il successo dipende dall'attenzione e dall'affidabilità della procedura, e questo è il criterio che può essere soddisfatto solo con una competenza professionale e con l'aiuto di attrezzature di alta qualità e su misura.