In the industrial production of foods with a long shelf life, the sterilization method dictates the engineering requirements of the entire production line. While often viewed solely as thermal processing, retort processing is, at its core, an issue of packaging integrity within the food industry. The sterilization vessel and the packaging equipment are separate, yet operate as one interdependent system. If the front-end packaging equipment does not function in a way that hermetically seals the packaging and is able to withstand the strong positive and negative pressures, the back-end sterilization process works as a means of failing the product.

This guide will explore the principles of retort processing, describe its use for particular categories of food products, and examine the importance of the interdependence of the front-end packaging system, in particular filling and seaming equipment, and the back-end retort machine systems.

The Core Definition: What Is Retort Processing?

So, what is retort processing exactly? Retort processing is a form of commercial sterilization that is pertinent to food products that are hermetically sealed in a container. It is also technically termed as in-container sterilization. Unlike aseptic processing where the product and container are sterilized in isolation and subsequently sealed together in a non-contaminated atmosphere, retort processing does not work that way. It is a high temperature, high pressure system that is applied to a package that alters its biological stability to ensure food safety.

This process works toward obtaining Commercial Sterility which is defined operationally. It does not mean the elimination of every microorganism, including the non-threatening ones. It means the removal of any pathogenic and spoiled organisms that can grow at room temperature, ensuring a safe shelf life.

Of these organisms, the most dangerous is Clostridium botulinum. It is an anaerobic bacterium, meaning it can live and thrive in sealed pouches and cans; it also produces and excretes a potent lethal neurotoxin. We use retort processing, which employs pressurized steam or hot water to heat the product to between 110°C and 135°C (230°F–275°F). This range of temperature is crucial as the spores of C. Botulinum is heat resistant, and will survive at the boiling point of water (100°C) and atmospheric pressure. This is a lethal heat treatment. The retort is the containment vessel that allows pressure to build, thus increasing the boiling point for effective food preservation.

Ideal Food Products for Retort Technology

The acidity (pH) of the food product and its physical state are the main factors in determining the suitability of retort processing. What is retort processing best used for? It handles a wide range of food types.

Low-Acid Foods (pH > 4.6)

Low-acid foods processed using a retort process are meant to be stored at room temperature. In low-acid conditions, spores of C. Botulinum can germinate and then secrete lethal toxins. Hence, it becomes mandatory to conduct high-temperature retort processing.

- Meat and Poultry: Canned luncheons, sausages, braised beef and poultry are shelf-stable after modifications of muscle fibers. This is consistent with high viscosity filling operations wherein vacuum packaging is critical.

- Wet Pet Food: This is a quickly growing industry. Retorted products are almost exclusively packed within high protein and moisture containing cans or pouches (e.g., gravy with meat chunks or loaf style).

- Ready-to-Eat Soups and Sauces: Non-acidic bases such as cream soup, bone broth, and meat based pasta sauces.

- Shelf-Stable Dairy products and Plant Proteins: Canned evaporated milk, bottled coffee beverages, or protein drinks packed in metal containers.

Constraints and Incompatible Products

Retort processing is naturally unfit for High-Acid Foods (pH < 4.6) like fruit slices, pickles, and acidic juices. The acidity of these foods alone inhibits Clostridium botulinum, making retorting is unnecessary. These foods have their temperatures below 100 °C. If retort temperatures are applied to high-acid fruit, the fruit’s pectin will degrade, and the resultant texture will be mushy, losing heat-sensitive vitamins and nutritional value.

Moreover, the prolonged heat of retorting also affects the product quality and sensory attributes of foods. The Maillard reaction may happen, resulting in color and flavor changes. While the flavor changes are desired in meat products (to create a cooked/roasted flavor), it is a drawback for foods that require freshness and crispness, like green vegetables.

The 3-Stage Retort Processing Workflow

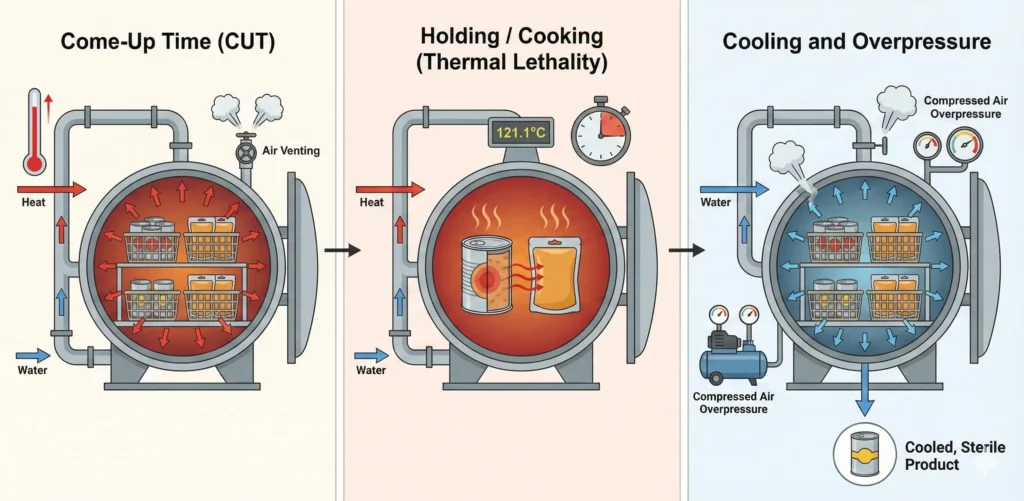

The operational cycle of a retort sterilizer is broken down into three distinct thermodynamic phases. Each phase applies physical stresses to the packaging, resulting in the need for strong front-end sealing.

- Come-Up Time (CUT)

During this stage, the heating medium (steam or water) comes into the retort chamber. The vessel’s internal temperature needs to reach the appropriate target for processing temperature. This often involves rapid heating to ensure efficiency. An essential criterion is the absence of ‘cold spots.’ The operator needs to guarantee the thermal equilibrium throughout the vessel so that every unit, regardless of position in the basket, is instantaneously at the target temperature. Air pockets within the vessel act as insulators and, therefore, need to be vented to ensure proper heat distribution.

- Holding / Cooking (Thermal Lethality)

The duration is determined by the F0 value, which is the heat process lethality, and is time adjusted to 121.1°C (250°F) for a minute. Once the temperature is sufficient, it is sustained for a determined time to allow for heat penetration. At the temperature target, it is sustained for a specified time. The heat must go to the geometric center, which is the freezing point, of the food. Solid foods (conduction heating) need longer processing times compared to liquid foods (convection heating).

- Cooling and Overpressure

This step is the most important and most difficult when it comes to packaging preservation. As the heating medium is taken out and cold water is inserted, the pressure within the retort chamber sinks. However, the food, inside the container, is still hot and the pressure inside the can or pouch is high due to steam creation in the package.

If the vessel pressure drops faster than the container’s internal pressure, pressure fluctuations will result in the container bursting or permanently deforming (buckling) the sidewalls of the container. This is why Overpressure (injecting compressed air into the vessel) is used to offset the containers internal pressure until the product has cooled enough.

Classifying Retort Sterilizers by Heating Method

According to the different formats of packs, it is required to use a specific type of retort to ensure the efficiency and safety of the package. The choice of backend equipment dictates the requirements for the frontend packaging line. Here are the main types of retort systems:

| Heizmethode | Mechanism | Primäre Anwendung | Key Advantages & Constraints |

| Steam Retorts | Saturated steam is injected directly into the vessel; utilizes latent heat of vaporization. | Starre Metalldosen (Steel or Aluminum) | Pros: Rapid energy transfer. Cons: Requires absolute air removal. Generally unsuitable for flexible packaging due to the lack of overpressure control during the heating phase (risk of bursting). |

| Water Spray / Cascade | Superheated water is sprayed from atomizing nozzles or cascaded from the top of the vessel (sometimes called steam water spray). | Flexible & Fragile (Retort Pouches, Plastic Trays, Glass Jars) | Pros: Allows for independent control of temperature and precise overpressure control during heating and cooling, protecting fragile seals. Heat distribution is highly uniform. Cons: Slightly more complex water circulation system than steam. |

| Water Immersion | Product baskets are completely submerged in superheated water (known as full water immersion). | Irregular Shapes (Large containers or shapes needing buoyancy support) | Pros: Buoyancy reduces structural stress on the container; provides the most uniform temperature distribution. Cons: Requires heating a large thermal mass of water, resulting in higher energy and water consumption. |

Aligning Front-End Packaging Equipment with Retort Sterilization

When designing a food processing line, one must consider the entire system as a single unit. The sterilization vessel operates based on the assumption that the container it is processing is completely sealed. If the front packaging equipment is incapable of producing a seal that can endure the extreme heat and pressure, the retort process will ultimately fail. Therefore, within a retort line, the retort packaging has the most safety critical role, as even minor seal defects can lead to high-pressure can ruptures or microbial contamination. As a result, the retort process dictates the filling and sealing equipment.

Metal Cans: Vacuum Sealing and Double Seaming Precision

When it comes to retortable rigid metal containers, the most critical factor is the mechanical tightness of the double seam, as it is the one and only protection against the risk of contamination. Standard atmospheric seaming is insufficient for retort applications.

- Vakuum und Unterdruck Versiegeln: High-performance seamers must be capable of vacuum sealing or negative pressure sealing. This process removes oxygen from the headspace before the lid is sealed. This is critical for two reasons: to prevent oxidative spoilage of the food or to maintain a vacuum that prevents the can ends from bulking (buckling) when the internal contents expand during the heating phase.

- Double Seam Precision: For Body Hook and Cover Hook overlap to meet industry standards(calc to >50%), the seamer rollers span and calibrations must be adequately set to produce an even seam throughout length the seamer runs. When the filler weakens at 121°C, the seal must hold firm enough to contain product hermetically. Therefore, the seamer must be equipped with higher quality machine parts in craftsmanship to guarantee the rollers are appropriately and even exert the same pressure on the product.

Levapack addresses these critical retort requirements through precision engineering. Our vacuum and nitrogen flushing seamers utilize CNC-machined components, ensuring consistent double seam overlap essential for withstanding 121°C sterilization. Constructed from heavy-gauge 304/316 stainless steel, Levapack machines resist corrosion in humid retort environments while delivering low residual oxygen (<3%) for premium shelf life of food. With over 18 years of experience serving global SMEs, we provide customizable, servo-driven sealing solutions that ensure every can enters the sterilization vessel hermetically secure.

Glass Jars: Thermal Shock Prevention and Headspace

Glass presents unique thermodynamic challenges due to its rigidity and brittleness.

- Headspace Control: The filling machine has to be able to manage volumes to a fine degree because, due to glass being non-stretchable, space is the only thing that is able to fill up with product. If there is not enough space, the jar will break, or the lid will be pushed off during the heating process. Piston fillers with servo control are often opted for due to their volumetric accuracy relative to these applications.

- Cap Security: The liner has to be softened and the vacuum has to be established first for a proper seal. The vacuum is the only thing that retains the liner in place around the glass finish without being loose. If not, the internal vacuum seal pressure built up inside the retort will be too much for the lugs to hold onto and the cap will pop off.

Retort Pouches: Servo Control and Seal Integrity

Flexible packaging like pouches are the most sensitive to pressure differentials.

- Residual Air Removal: The presence of air inside a retort pouch is critical. Air will fully expand at a much quicker rate than water or food. Therefore, if the packing machine is not efficient enough at removing leftover air, the pouch will balloon in the retort and then burst. Therefore, retort packers, both premade and form-fill seal, need to be able to remove residual air are ones with efficient vacuum packers.

- Servo-Driven Stability: Modern lines feature servo motor technology to control the opening, filling and sealing of pouches. This technology allows the pouch mouth to be opened to an exact width and the filling nozzles to plunge fully into the pouch, eliminating any opportunity for the filling to be contaminated in the seal area. Contaminating the seal area with food residue will create an imperfect seal during the high-heat sealing process.

Retort Alternatives: Comparing Common Sterilization Methods

Retort processing is not the only option for food preservation. The type of sterilization method chosen is based on the product’s acidity, viscosity, and desired shelf life. The following table compares retorting to its main alternatives for straightforward process selection.

| Merkmal | Retort Processing | Pasteurisierung | Aseptic Processing | Hot Fill |

| Process Logic | Package→Heat (In-container) | Package→ Heat (Low Temp) | Heat→Package (Separate) | Heat→Package (Fill Hot) |

| Primary Target | Clostridium botulinum spores | Pathogens / Yeasts | Spores & Bacteria | Yeasts / Molds |

| Temperatur | High (110°C – 135°C) | Moderate (< 100°C) | Ultra-High (135°C – 150°C) | High (85°C – 95°C) |

| Ideal pH | Low Acid (> 4.6) | High Acid (< 4.6) | Both (High & Low Acid) | High Acid (< 4.6) |

| Typische Produkte | Canned Meat, Pet Food, Soups | Fruit Cups, Pickles | UHT Milk, Juice | Tea, Ketchup, Sauces |

| Equipment Cost | Mäßig | Niedrig | Sehr hoch | Niedrig |

| Packaging Limits | Must withstand high heat/pressure | Standard packaging | Complex sterile packaging | Heat-resistant bottle |

Conclusion: Integrating Your Seamer with the Retort Line

The efficiency of a retort line is defined by the synchronization between the continuous output of the packaging machines and the batch processing nature of the sterilization vessels. This requires equipment that is not only fast but robust and adaptable to various material types (solids, pastes, liquids).

For manufacturers scaling their production of shelf-stable foods, integrating Retort-Ready infrastructure is a fundamental requirement for product quality and safety, not an optional upgrade. Beyond standalone seamers, Levapack specializes in engineering customized packaging lines tailored to your specific throughput and layout constraints. Contact Levapack today to analyze your production parameters and design a cohesive solution—from filling to sealing—that aligns perfectly with your sterilization objectives.