A double seam is not just a closure in the canning industry, it is the most important barrier between your product and the outside world. In the case of food, beverage, and industrial goods manufacturers, the product integrity of this seam determines the shelf life, safety, and brand reputation.

Nevertheless, most quality control managers and line engineers take the issue of double seam inspection from a reactive perspective. They pay much attention to double seam defects—they record the measurements, log the failure, and dispose of the product. Measurement is not the answer, although it is a vital part of the quality control process.

In order to have zero defects, you need to change your mindset towards inspection to optimization. Data from a double seam inspection is not just a pass/fail grade, it is a diagnostic report of the health of your seaming machine. Any change in the seam thickness, overlap, or body hook length is a direct indication that a particular mechanical part, a roller, a lifter, or a seaming chuck, needs to be changed.

The guide is addressed to production managers and engineers who desire to bridge the gap between seam inspection data and machine mechanics. We will look at the way to convert product quality measurements into mechanical changes that can be implemented, so that your production line will work with accuracy and efficiency.

The Core Definition of Double Seam

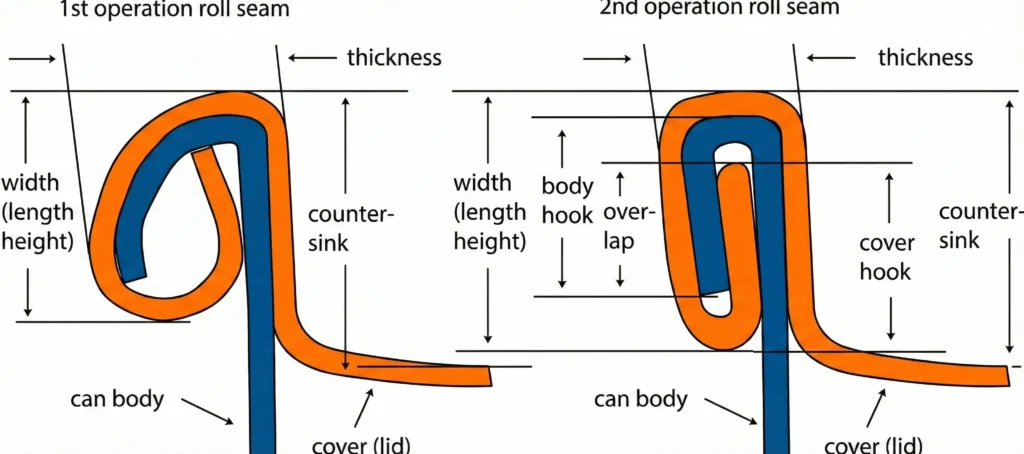

The double seam is a hermetic seal that is created by interlocking 5 layers of metal mechanically. These layers are three layers of the can ends (the lid) and two layers of the can body. Essentially, these pieces of metal must be folded correctly to prevent leakage.

The seaming process takes place in two operations. The initial structure is made by curling the cover hook around the body hook in the first operation. These layers are squeezed together to form a gas-tight seal in the second operation. This mechanical interlocking is what needs to be understood in order to diagnose the failure of a seam. In case the physical overlap of these five layers is not enough, or the second operation formation is too loose, you will end up with a leaking double seam.

How to Inspect: Visual vs. Destructive Methods

Quality control must be done in two prongs: firstly, regular non-destructive visual inspections to detect gross failures, and secondly, periodic destructive tests to ensure internal integrity using specialized seam inspection equipment.

- Visual Inspection (Non-Destructive)

Frequency: Every 15–30 minutes at the seaming station.

Purpose: To detect gross machine failures or “Drift” early enough before it becomes critical.

The operators are supposed to physically rotate the can and touch the seam. You are looking for:

- ドループ: A smooth projection of the seam downward at the crossover.

- ヴィー A sharp “V” shaped projection, often indicating a loose first operation seam.

- シャープな縫い目: A sharp edge on the top edge of the can body inside top of the seam (indicates chuck issues).

- Skidders/Deadheads: Evidence that the can slipped during double seaming.

- Teardown Inspection (Destructive)

Frequency: At the beginning of the shift (First-off), change of shift, and after every 4 hours.

Purpose: To measure the internal double seam components and tightness rating.

The Procedure:

- Sectioning: With a special seam saw, cut a cross-section of the seam. This enables you to put the can on the can seam inspection equipment to measure Overlap, Body Hook, and Cover Hook.

- Stripping: Peel the remainder of the cover hook off the body of a can using a seam stripper (or nippers).

- Tightness Rating: Check the inside of the can body hook and the removed cover hook. You will find some seam operations left behind wrinkles. A significant seam impression is often a good sign.

- No wrinkles (100% Tightness): Ideal (or even too tight).

- Slight wrinkles (90% Tightness): Normal indication of adequate tightness.

- Deep wrinkles extending to the bottom (Loose): FAIL.

Linking Inspection Metrics to Seaming Machine Mechanics

Now that you have your measurements, how do you use them?

Your seams should have a certain range of tolerance to be in compliance with regulatory requirements such as the FDA (21 CFR 113) or industry standards such as the ISBT. But it is not half the battle to see a number out of spec. You must know what bolt to turn.

The critical Industry Standards (Safe Zones) are directly mapped to the Machine Components that control them in the following table. This is your main diagnostic reasoning for double seam quality.

| Parameter & Safe Zone (Standard) | Definition & Why it Matters | Controlling Machine Part |

| Body Hook(Spec ± 0.15 mm) | Def: Flange bent downward. Criticality: Essential for creating the interlock structure. | First operation roll (Height and depth of the groove). |

| Overlap(> 1.0 mm / 0.040″) | Def: Length of interlock between hooks. Criticality: The primary barrier against bacterial ingress (Leakers). | Second operation roll & Lifter Pressure (Primary) Also affected by the 1st Op geometry. |

| Tightness(> 75% – 80%) | Def: Absence of wrinkles on the cover hook. Criticality: Ensures sealing compound fills voids. | Second operation roll Profile (Tightness setting and spring pressure). |

| Countersink(Spec ± 0.15 mm) | Def: Depth from seam top to lid floor. Criticality: Affects seam strength and pressure resistance. | Chuck Height & Alignment (and Lifter spring stability). |

| Cover Hook (Spec ± 0.15 mm) | Def: Lid curl bent upward. Criticality: Works with Body Hook to create overlap. | First operation roll (Interacts with Chuck) |

The First Operation: Forming the Hooks (Body & Cover Hook)

The double seam is based on the first operation. It decides how much material is left to use in the final seal. In particular, it constitutes the Body Hook and the Cover Hook. These are the two metal structures that will finally have to connect with one another. A good first operation seam is crucial, if they are too short or deformed at this stage, the second operation will not be able to rescue the can.

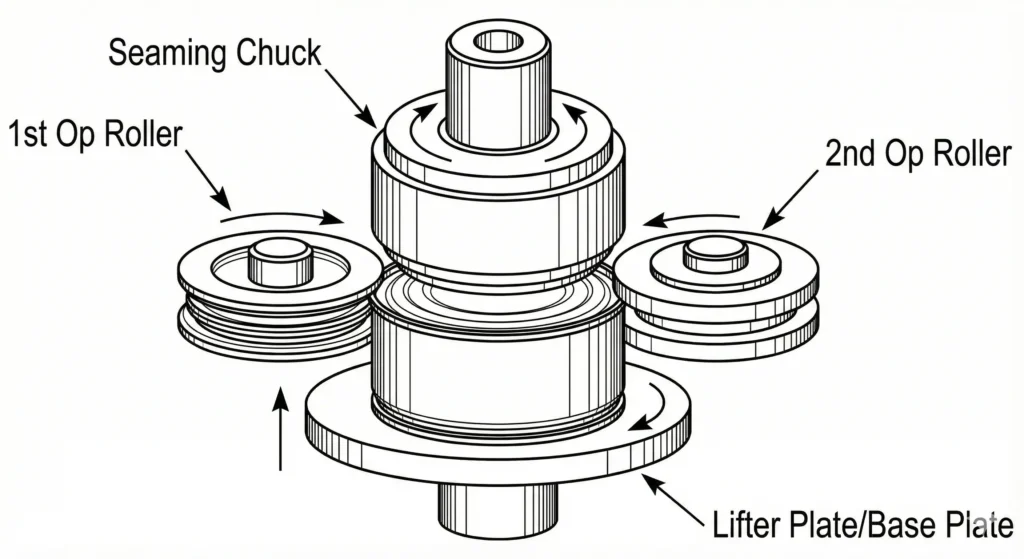

These hooks are produced by the first operation roll only. The roller forces the curl of the lid beneath the edge of the can body flange. The amount of material bent depends on the depth of the roller in comparison to the chuck (pin height) and the profile of the roller groove.

In case your Body Hook is not consistent, do not look at the second operation roll. You need to check the first operation roll. Does the roller wobble due to the wear of the bearing? Is the driving cam of the roller giving even pressure?

The Second Operation: Creating the Seal (Overlap & Tightness)

The hooks are loose after they are formed. The second operation is the cause of overlap (the real sealing distance) and seam tightness (the compression of the sealant compound). The overlap cannot be measured directly without cutting the can, but it is calculated using hook lengths and seam thickness. Tightness is determined by peeling the seam and examining the cover hook to see whether it has any wrinkles.

The second operation roll controls this. The profile of this roller is flatter than that of the first. It is its task to smooth the folds made in step one to create a tight seam.

One of the mistakes made is applying the wrong amount of pressure in this case to seal a leak. Overpressure may overstretch the metal, creating a loose seam or decreasing overlap (a flaw known as ironing out). The objective is proper compression. This involves a stable seaming head. When the roller pressure varies as a result of ineffective motor control, then you will observe uneven tightness in a single production run.

The Structural Foundation: Countersink & Seam Height

The distance between the top of the seam and the flat panel of the lid is the countersink depth. The external dimensions vertical measure is seam height.

These measurements are the signs of the vertical stability of your machine. The seaming chuck (Press Head) and the Lifter (Base Plate) control them.

The lid is held by the chuck and the can body is pushed up by the lifter. When the lifter spring is too weak, the can will skid or fall down in the seaming, and the Body Hook will be long and the seam height short. Unless the chuck is perfectly centered on the rollers, the Countersink will be uneven around the diameter.

Troubleshooting Guide: Diagnosing Machine Faults From Inspection Data

A defect detected by inspection equipment will cause the production line to stop. The sooner you identify the cause of the problem, the less you pay in terms of downtime. The following is a roadmap to the translation of common defect data into mechanical solutions.

| Defect Detected | Likely Mechanical Cause |

| シャープシーム | Chuck is set too low or worn chuck lip. |

| Low Overlap | Second operation roll loose or Lifter pressure low. |

| フォールス・シーム | Damaged flange or Bearing play (wobble). |

| Deadhead (Skidder) | Lifter pressure is too low or the Chuck slips. |

Fixing Sharp Seams by Adjusting Chuck Alignment

One can feel a sharp edge at the top inside edge of the seam. This is hazardous to the consumer and usually cuts through the seam resulting in instant leaks. This is nearly always a Chuck problem.

- Check Vertical Alignment: The chuck is probably too low in relation to the rollers. This causes the metal to bend over the lip of the chuck too violently. You have to increase the pin height setting.

- Inspect Wear: Examine the lip of the chuck. If the edge is chipped or unevenly worn, it will cut the metal.

Solving Low Overlap via Roller Tightness

The computation indicates that there is not enough overlap (less than 1.0mm or whatever your standard is). This implies that the hooks are not hooking in deep enough. This involves a multi-step verification, often checking the radius of the cover hook.

- Check Lifter Pressure: When the can is sliding down, the body hook is not formed. Apply more tension to the spring on the base plate.

- Adjust Second Operation Roll: When the hooks are not overlapping but long enough, the second operation roll can not push deep enough. The roller should be tightened to ensure a visible pressure ridge.

- Warning: Do not overtighten. Over-tightening leads to the stretching of the metal and the reduction of overlap. It is a fine balance that needs a stable machine frame.

Correcting False Seams: Bearing and Flange Issues

The seam appears flawless on the outside, but a dismantling shows that the body hook and cover hook did not even touch. The can is not sealed. It is a serious safety failure. This is usually due to mechanical slop or misalignment in the cycle.

- Check Bearings: When roller bearings are playful, the roller may bounce back when it strikes the can seam, and it will not compress.

- Check Infeed: If the can flange is bent before it hits the seamer, the hooks won’t engage. Check the star wheel and turret timing.

Integrated Quality Protocol: Daily Setup & Inspection Workflow

Routine is the consequence of consistency. In order to reduce defects, you have to make double seam inspection a part of your daily machine setup workflow. This protocol takes you out of the bad cans catching business to the bad cans preventing business.

Phase 1: Pre-Start Machine Check (The Visual Method)

The operator should conduct a visual audit before the machine runs one can. It is not the can that is measured, but the preparedness of the machine.

- Debris Check: Check the rollers and chuck to see whether there is any aluminum dust or lacquer. This debris modifies the effective diameter of the tooling and changes the seam dimensions.

- Tooling Condition: Visually inspect the chuck lip for chips.

- 潤滑: Have all the moving parts lubricated.

Phase 2: The “First-Off” Calibration (The Destructive Method)

Do not begin full production without a teardown using proper seam inspection tools.

- Warm-up: Run the machine for 5-10 minutes. Seamers expand slightly as they heat up; settings made on a cold machine will drift.

- The Tear Down: Take the first 3 consecutive cans. Perform a full destructive test.

- Calibration: When the tightness is not 100% (or your standard) change the 2nd operation roller spring force at once. Do not go on until the first-off samples are perfect.

Phase 3: Interval Monitoring (Non-Destructive & Sampling)

When production is started, you cannot dismantle all the cans.

- Frequency: Check after every 30 minutes in high-speed lines (such as our 50 cans/minute models). In the case of slower lines, one hour can be enough.

- Data Logging: Document these intervals. When you notice a trend (e.g. the seam height is gradually rising), then it means the machine is drifting (a locking nut might be loose or the lifter spring is heating up).

Selecting Inspection Tools for Rapid Machine Calibration

Manual tools and automated systems are often the subject of debate. We recommend that clients select tools according to their feedback speed, rather than their technology. This is aimed at ensuring that data is availed to the operator promptly to enable him/her to make adjustments to the machine.

- Manual Tools (Micrometers/Calipers):

- 長所だ: Inexpensive, durable.

- 短所だ: Subjective (measured differently by different operators), slow, and manual data recording.

- Use Case: Best for low-volume startups or as a backup.

- Automated Vision Systems (Seam Monitors):

- 長所だ: Objective, extremely fast, digital data storage.

- 短所だ: Higher initial cost.

- Use Case: Essential for any serious production line where traceability is required.

The most useful tool is the one that fits into your workflow. An automated inspection unit of 50,000 dollars is of no use when the data is stored in a computer office. The seamer should be beside the monitor. When the system signals a Low Body Hook, the operator must be aware that he/she need to inspect the first operation roller.

Never invest too much in technology that you do not require, but never under-specify your quality control. The protocol of a craft producer who seals 20 cans per minute is not the same as a beverage plant that seals 500.

The following matrix can be used to identify the right inspection setup to use at your level of production:

| 生産規模 | Typical Output (CPM) | Recommended Inspection Setup | Value Proposition |

| Micro / Pilot Line | < 15 CPM | Manual Micrometer + Seam Saw | Low Capital Cost: Ideal for businesses where operators have ample time to measure cans manually between cycles. |

| SME / Mid-Sized | 20 – 80 CPM | Desktop Video Seam Monitor (VSM) | Accuracy & Speed: Provides the necessary digital audit trail and eliminates operator error without the cost of inline automation. |

| High-Volume | 100+ CPM | Inline X-Ray or Fully Auto Vision | Real-Time Sampling: Necessary when production moves too fast for human sampling; detects statistical drift instantly. |

結論

Double seam inspection is not a passive activity of writing numbers, but it is an active interaction with your machinery. Any micron of variation in your inspection record is a murmur of your machine telling you what it wants, whether it is a roller setting, a spring, or a chuck.

Nevertheless, a high-quality machine is the basis of a perfect seam. A seamer that is not structurally rigid or has component precision cannot be fixed with any amount of adjustment.

At Levapack, we don’t just sell machines; we provide stability. With CNC-machined components accurate to 2μm, premium servo controls, and heavy-duty stainless steel construction, our custom canning solutions are built to hold their settings shift after shift. We support manufacturers in over 100 countries, helping them move from troubleshooting defects to optimizing production.

Are you tired of constantly tweaking old equipment just to pass seam inspections?

Contact Levapack today. Let’s discuss a high-precision, zero-defect canning solution tailored to your specific product and factory layout. From powder to paste, we have the engineering expertise to seal your success.