The last step of your production line is packaging, which is the last step before your customer receives your product: a pharmaceutical product, a durable chemical output, or one of many food products. At this stage, the product is converted from a commodity to a sellable unit among consumer goods.

To manufacturers and procurement officers, the variety of packaging machinery available for various industries may appear to be never-ending. There are thousands of types of machines, each claiming to be the solution to your problem. The problem is, each machine is only as good as how well they fit your reality. For example, a machine that fills paint buckets will not just ruin a packaging line of dairy. The machine will also destroy the line due to poor engineering standards, not lack of power.

This guide will simplify the complexity of packaging operations by treating packaging machines not just as hardware, but as a collection of dedicated tools. Each serves a different role in business operations, helping manufacturers understand the specific needs required to satisfy demands for product quality. Understanding this gives insight to answer the operational needs and requirements of specific types of packaging machines to protect the product.

How Industry Requirements Dictate Machine Design

The biggest and most dangerous assumption made while getting a packaging machine is thinking that packaging machine manufacturers are all selling the same utility—that every company selling fillers is selling a filler and every company working with seal machines is selling a sealer. This oversimplification is dangerous as the mechanical movement of getting a product into a container might look the same, but across industries, the engineering boundaries governing that movement is completely different.

Every machine has an environment and regulations governing the design identity. That design is a function of four fundamental pillars: Hygiene, physical state, explosion proofing, and the final look. Disregarding any of these pillars does not just put the machine at risk. It also exposes the company to regulatory breaches, product safety issues, and potential contamination.

The table below shows the core pillars and how they shift across different types of industries with the determining “DNA” of the machines:

| 寸法 | フード&ビバレッジ | 医薬品 | Chemicals & Industrial | 化粧品 |

| 主要目標 | Safety & Shelf Life: Preventing bacterial growth and oxidation. | Precision & Compliance: Zero dosage error and patient safety. | Durability & Safety: Surviving corrosion and preventing explosions. | Aesthetics & Finish: Flawless visual presentation of the product. |

| Sanitary Standard | High: Requires CIP (Clean-in-Place) systems and 304/316 Stainless Steel. | Critical: Ultra-high polish (Ra < 0.4µm), validation-ready, sterile environment. | Low/Moderate: Focus on chemical resistance rather than bacterial control. | Moderate/High: Focus on preventing cross-contamination between scents/colors. |

| Physical State | Varied: Liquids, pastes (with chunks), powders, granules. | Precise: Micro-dosing of powders, tablets, sterile liquids. | Bulk: Heavy viscous liquids, hazardous powders, volatile solvents. | Viscous: Gels, creams, waxes, often prone to foaming. |

| Explosion Proofing | Required for dusty environments (flour/sugar) due to dust explosion risk. | Required for specific solvent-based coating processes. | Critical: Must meet ATEX/Class 1 Div 1 standards for flammable chemicals. | Required for alcohol-based products (perfumes, aerosols). |

| 美学 | Functional: Focus on seal integrity and tamper evidence. | Functional: Focus on clarity, labeling accuracy, and track & trace. | Industrial: Focus on secure closure and leak prevention. | Critical: Perfect label alignment, scratch-free containers, “shelf appeal.” |

The understanding of this table is key to being able to choose equipment and provides a foundation of the information available that applies to the types of packaging machines that we will analyze.

Food and Beverage Packaging Machinery Overview

Food and beverages is the biggest and most diverse category in the packaging machinery industry. In this field, machinery does more than package; it also encapsulates and preserves the product to maintain freshness. Controlling the microbial environment and shelf life is the primary engineering goal.

Equipment in this sector undergoes life cycles exceptionally more severe than in other industries. Machines are expected to function at dailey cut daily repetitive wash downs, and high consumer demand they have. harsh, hot, corrosive chemical wash downs. Consequently, the defining characteristic of a true food packaging machine is a “washdown design”, featuring sloped surfaces to prevent fluid pooling, IP69K-rated electronics moisture-proof, and food-grade 304 or 316 stainless steel construction.

The same sanitary standards may apply, but the mechanical demands are different between solid foods and liquid beverages.

Food Packaging Machinery: Handling Solids, Pastes, and Powders

The food industry also deals with complexity in the physical form of the product. The various products may be free-flowing granules, fine powders, viscous pastes, and delicate solids. The focus of the machinery is on the weight accuracy, preservation of the product texture, and modifications in the atmosphere surrounding the product.

To manage this diversity, food production lines utilize a combination of weighing, filling, and sealing technologies tailored to the product’s flow characteristics:

| Packaging Stage | マシンタイプ | 代表的なアプリケーション | Primary Function & Logic |

| Dosing & Weighing | Multihead Weighers | Chips, Nuts, Frozen Vegetables, Candy. | Speed & Accuracy: Uses combinatorial logic to weigh product in multiple buckets simultaneously, selecting the combination that matches the target weight closest to zero error. |

| Volumetric Cup Fillers | Rice, Beans, Popcorn, Sugar. | Volume-based: A cost-effective solution for free-flowing granules where consistent density allows volume to equal weight. | |

| 一次梱包 (Filling & Sealing) | オーガー・フィラー | Flour, Spices, Coffee Powder, Baking Mixes. | Dust Control: Uses a screw drive to force non-free-flowing powders into containers, minimizing dust clouds. |

| ピストン充填機 | Tomato Paste, Hummus, Honey, Salsa. | Viscosity Handling: Works like a syringe to handle thick pastes and liquids with chunks without crushing the particulates. | |

| VFFS(縦型フォームフィルシール) | Potato Chips, Cereal, Salad Mixes. | Gravity Fed: Forms a bag from a roll of film and fills it vertically; ideal for loose products dropped by gravity. | |

| HFFS (Flow Wrappers) | Energy Bars, Cookies, Frozen Pizza. | Horizontal Protection: Wraps individual solid items as they move along a conveyor; ideal for delicate items that cannot be dropped. | |

| Thermoformers | Fresh Meat, Cheese, Tofu. | Vacuum Forming: Heats a plastic sheet to form a tray, fills it, and seals it under vacuum to extend shelf life. | |

| 二次梱包 | Cartoners | Cereal boxes, Frozen meal boxes. | Protection: Inserts the sealed bag or tray into a paperboard box for retail display and physical protection. |

Below, we analyze the specific engineering mechanisms of the most critical machines from this list to understand how they handle different material states:

Rigid Canning and Seaming (Powders & Pastes)

In the case of high-value powders, like infant formula, and viscous pastes such as honey, rigid canning is the durable gold standard. Filling technologies here are specialized viscosity.

- Auger Fillers: This technology is used for powders. A rotating screw auger makes a precise dose, and then a can is filled with products like milk powder and spices.

- ピストン充填機: This filling technology, often used for viscous products, works like a syringe. With products like tomato paste, honey, and chunky salsa, a piston draws the product and then releases it, but if there are chunks in the product, they can be crushed.

In the specialized world of can and jar packaging, generic solutions often fail to meet the specific needs of growing manufacturers. レバパック bridges this gap. We focus specifically on SMEs (Small and Medium-sized Enterprises) that require the precision of top-tier automation.

Levapack empowers manufacturers with versatile equipment engineered to handle any container material or product viscosity. Built in our facility using advanced CNC machining centers, every machine utilizes food-grade 304 or 316 stainless steel for the frames and contact parts, guaranteeing the hygiene and corrosion resistance your industry demands. But we provide more than just hardware. Our dedicated expert team offers one-on-one consultation to engineer a solution tailored to your specific needs, whether you require a single high-precision machine or a fully integrated turnkey line. With Levapack, you get industrial-grade reliability customized for your business.

Flexible Packaging (VFFS & HFFS)

Solid foods like chips, candy, cereals, and frozen nuggets often do not require a rigid container. In these scenarios, flexible film or wrapping is the best option using various packaging materials.

- VFFS (Vertical Form Fill Seal): Envision a roll of plastic film. The machine pulls it down with a friction belt, forms the film into a tube, seals the bottom, drops a portioned product in from a multi-head weigher, and seals the top. The vertical alignment allows the entire system to drop product into the bag using the force of gravity as is common practice for products like potato chips and coffee beans.

- HFFS (Horizontal Form Fill Seal): These are also referred to “Flow Wrappers”. A product moves horizontally along a conveyor belt and gets sealed in a film. This is generally for singular products like chocolate bars, cookies, or biscuit trays which are too fragile to be dropped from a height.

Modified Atmosphere and 真空 パッケージング

For proteins (meat, seafood) and pre-prepared meals, oxygen is a foe. It enables bacterial growth and oxidation (browning).

- 地図 (改質雰囲気包装): These machines flush the package with a gas mixture (generally inert nitrogen and bacteriostatic carbon dioxide) before sealing. This technology enables a steak to be kept fresh and red for several days in a fridge, way better than just simple wrapping.

- 真空 パッケージング: These machines quickly remove all the air from the pouch and seal it. This is a standard for thermoformed pouches of cured meats and cheese, as the atmosphere must be removed completely to prevent the survival of aerobic bacteria.

Beverage Packaging Machinery: Liquid Flow and Thermal Processing

Flow dynamics, pressure regulation, and thermal processing are the top priorities in the beverage industry. Unlike food machines which manage “chunks” or “weights” (as in, the weight of the product), beverage machines manage, “levels” (the height of the liquid in the container), “carbonation” and “sterility” at incredible speeds.

Beverage lines are characterized by high-speed rotary systems that integrate rinsing, filling, and capping into synchronized blocks:

| Packaging Stage | マシンタイプ | 代表的なアプリケーション | Primary Function & Logic |

| Pre-Treatment (Cleaning) | Bottle Rinsers / Air Cleaners | All beverage lines (Glass, PET, Cans). | Hygiene: Inverts containers and uses ionized air or treated water to remove dust and particles before filling. |

| 一次梱包 (Filling & Sealing) | グラビティフィラー | Still Water, Flat Wines, Juices (non-pulpy). | Consistency: Uses gravity to flow liquid into the bottle. Simple, low-maintenance, and cost-effective for non-carbonated, low-viscosity liquids. |

| Isobaric (Counter-Pressure) Fillers | Beer, Soda, Sparkling Water, Energy Drinks. | Carbonation Control: Pressurizes the bottle with CO2 to match the tank pressure before filling, preventing foaming and preserving fizz. | |

| Hot Fill Machines | Isotonic Sports Drinks, Teas, Juices. | Sterility: Fills liquid at high temperatures (85°C+) to sterilize the bottle interior and cap, eliminating the need for preservatives. | |

| Aseptic Fillers | Shelf-stable Milk, Cold Brew Coffee. | Cold Sterilization: Fills sterilized product into sterilized containers in a sterile environment (at room temp) to preserve flavor and nutrients. | |

| 缶シーマー | Craft Beer, Soda, Canned Coffee. | Hermetic Seal: Mechanically folds the can lid onto the body (double seam) to create a leak-proof, pressure-resistant seal. | |

| キャッピングマシン | Screw caps (PET), Crown caps (Beer), Corks (Wine). | Closure: Applies the final seal with precise torque control to ensure leak prevention without stripping threads. | |

| 二次梱包 | Multipackers | 6-pack Beer rings, 12-pack Soda cartons. | Grouping: Groups individual containers into sales units using plastic rings, cardboard clips, or paperboard cartons. |

To grasp the machinery differences and choose among different types of packaging machines, an analysis of the three most prominent types of drinks, Carbonated, Dairy, and Spirits, is in order.

Carbonated Beverages (Beer & Soda): The Pressure Challenge

Beer cannot be poured straight into a can, for example, because the CO2 will be released and the beer will foam and overflow. These lines use Counter Pressure (Isobaric) Fillers.

- The Process: The first step for the machine is sealing the container, then inflating it with CO2 until the internal pressure matches that of the filling tank. Only when the pressure is equal will the liquid fill the container slowly to prevent foaming.

- Oxygen Control: Machinery for beer especially has a feature called “Double Pre-Evacuation” to remove all oxygen before filling. This is because even a small amount of oxygen can ruin the beer’s flavor profile.

Dairy Products (Milk & Yogurt): The Hygiene Challenge

Milk is a low-acid “living” liquid, meaning it is the most difficult type of liquid there is to package, but with this comes the difficulty of designing the machienery to be sterile enough.

- ESL vs. Aseptic: Fresh refrigerated milk will use ESL (Extended Shelf Life) machines that have HEPA filters in their chambers. Shelf-stable milk will use Aseptic Filling, so the bottle and the cap are chemically sanitized (with Hydrogen Peroxide vapor) and filled in a sterile tunnel.

- Light Protection: Dairy packaging machines must use opaque packaging material (HDPE or multi-layer PET), since light also causes riboflavin degradation and spoilage off-flavors.

Spirits and Wine: The Visual Challenge

For high-value glass bottles like whisky or vodka, the consumer demands visual perfection.

- Level-Sensing Fillers: While volumetric fillers are designed to dispense a set volume (e.g., 500 ml), for spirts machinery, vacuum or Level-Sensing Gravity Fillers are used. These overfill every bottle to the same visual level in the neck, regardless of glass thickness. This way, when bottles are displayed together, their fill heights are uniform.

Pharmaceutical and Medical Packaging Solutions

In the pharmaceutical industry, the spoiling of product is replaced with the danger of products impacting patient’s health. Thus a NO ERROR policy is adopted, and the machinery required to meet the highest of standards, be they regulatory (e.g. FDA 21 CFR Part 11) or quality (e.g. cGMP). With the focus on throughput, pharmaceutical machinery is completely different than the high-speed beverage lines. A vaccine vial cannot have a single tablet missing, nor can it be off by 1% in dosage. Therefore, a pharmaceutical line today is integrated with vision systems on every single one of the tablets. They have to be of such high quality, utilized ‘clean design’ sanitary stainless steel in order to be easy to sterilize, and thus can prevent contamination in sterile conditions.

| Packaging Stage | マシンタイプ | 代表的なアプリケーション | Selection & Buying Logic |

| 一次梱包 | Blister Packaging Machines | Solid doses (Tablets, Capsules) sealed in PVC/Alu or Alu/Alu pockets. | Barrier Protection: Essential for humidity/oxygen-sensitive drugs. Must ensure hermetic sealing and often includes “pinhole detection” systems. |

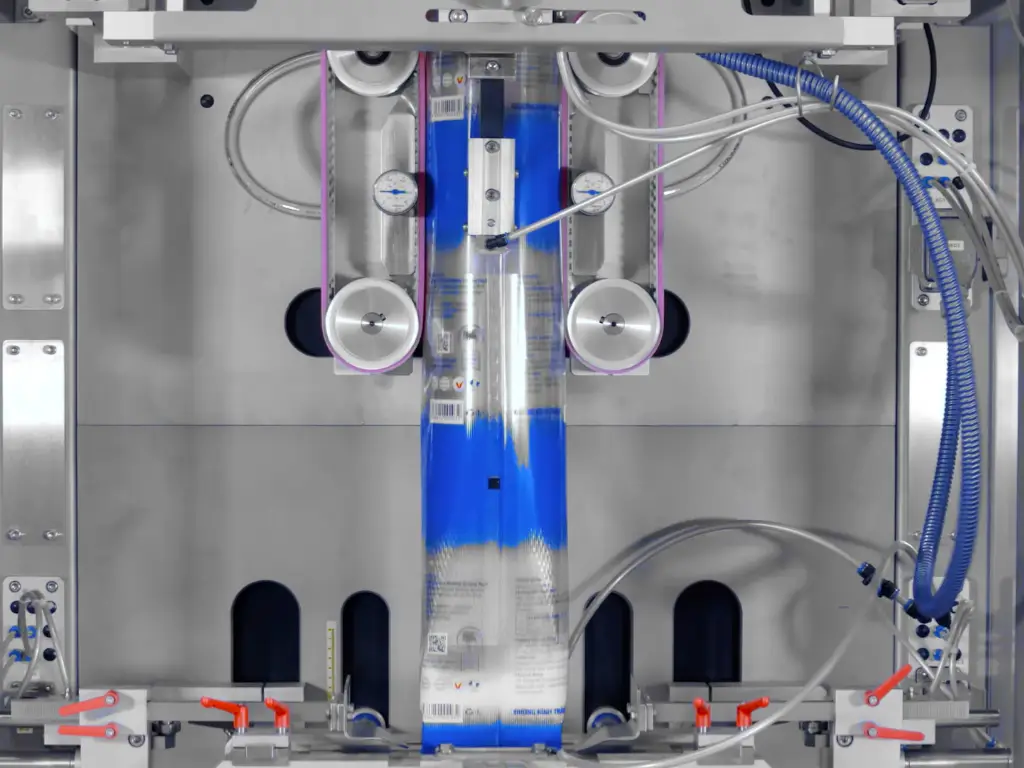

| Liquid Filling & Stoppering Lines | Vials, Ampoules, Syringes (Vaccines, Injectables). | Aseptic Integrity: Requires integration with Laminar Flow Hoods (RABS) or Isolators. Must feature precision torque control for capping to ensure seal integrity without cracking glass. | |

| Tablet & Capsule Counters | Loose pills packed into rigid bottles or jars. | Counting Accuracy: 100% accuracy is non-negotiable. Modern lines use electronic sensors or high-speed cameras rather than mechanical slats to verify count before filling. | |

| Tube Filling Machines | Ointments, Gels, Creams (Topical medications). | Material Compatibility: Metal tubes require folding stations (for airtightness), while plastic tubes use hot air sealing. Clean cut-off nozzles are vital to prevent product stringing. | |

| 二次梱包 | カートニングマシン | Inserting blisters/bottles + leaflets into individual boxes. | Compliance & Info: The most critical secondary machine. It automatically folds and inserts the Patient Information Leaflet (PIL) and verifies the presence of both product and leaflet before closing. |

| Bundling/Banding Machines | Grouping multiple cartons together (e.g., 10-packs) using film or paper bands. | Traceability Aggregation: Often the first step in aggregation where individual serial numbers are linked to a bundle, facilitating Track & Trace requirements. |

Cosmetics and Personal Care Packaging Equipment

In the beauty business, packaging is the key to the market. Customers purchase dreams and status, and the outer container must sustain that vision. Here, producers must address the complexity of high-viscosity products, especially thixotropic body butters that change viscosity when stirred, and rapid packaging reconfigurations determined by fickle fashion for cosmetic products.

Agility, or the ability to change one’s focus quickly, is the primary design characteristic needed by the machinery in this industry. Equipment is demanded to facilitate tool-less changeovers in under 30 seconds from filling and capping round jars to diamond-shaped bottles. Moreover, the filling, capping, and transporting systems must be ‘soft-touch’ so that glistening, expensive, and high-gloss containers are free from scratches and abrasions during each process for cosmetics.

| Packaging Stage | マシンタイプ | 代表的なアプリケーション | Selection & Buying Logic |

| 一次梱包 | Monoblock Fillers & Cappers | Premium Lotions, Shampoos, Foundations in bottles/jars. | Footprint & Precision: Combines filling, plugging, and capping in one compact rotary starwheel. Uses “pucks” (holders) to stabilize irregular-shaped cosmetic bottles during high-speed transport. |

| Tube Filling & Sealing | Toothpaste, Hand Creams, Face Wash, Sunscreen. | Aesthetic Sealing: For plastic/laminate tubes, Ultrasonic or Hot Air sealing is preferred to create a clean, curved seal that looks attractive on retail shelves. | |

| Sachet/Pouch Filling Machines | Face masks, Sample packs, Travel-size creams. | Leak Prevention: Critical for liquid cosmetics. High-quality sealing jaws are required to prevent leakage of oils or serums inside magazines or handbags. | |

| 二次梱包 | High-Speed Cartoners | Perfume boxes, Luxury Cream jars, Makeup kits. | Surface Protection: Unlike food cartoners, these must handle delicate, high-gloss cartons without scratching (scuffing). often utilize “tuck-in” closures rather than glue for a premium unboxing experience. |

| Overwrapping Machines | Perfume boxes, Gift sets. | Shelf Appeal: applies the “cigarette-style” tight cellophane wrap with diamond-fold ends. This signals “tamper-proof” and “luxury” to the consumer, distinguishing high-end products from drugstore brands. |

Chemical and Industrial Packaging Systems

Pharmaceutical cleanrooms are unable to extend operations to the Industrial Manufacturing section. This section has dangerous working conditions that are often filled with damaging Industrial Hygiene and Explosion Risks (such as corrosive fume-filled environments and diffuse explosive environments). Therefore, the primary engineering mandates are Durability and Hazard Control.

You cannot build a machine for hydrochloric acid using standard aluminum or copper, as they will dissolve. Equipments must, however, be made of more expensive and specialized engineering materials (fiberglass and durable plastics or higher grades of alloys like Hastelloy). There is also a significant scaling up of the packaging from retail container sizes to bulk sizes of 200L drums or 1000L IBC totes. In this industrial field, obtaining Safety Certification, e.g., ATEX for means of machinery working under explosive environments, is often a basic compulsory requirement.

| Packaging Stage | マシンタイプ | 代表的なアプリケーション | Selection & Buying Logic |

| 一次梱包 | IBC & Drum Fillers | Bulk Lubricants, Solvents, Industrial Acids (200L Drums, 1000L Totes). | Safety & Static Control: Must use “Subsurface” filling lances (diving nozzles) that fill from the bottom up to prevent foaming and static electricity buildup—critical for flammable solvents to prevent explosions. |

| FFS (Form Fill Seal) for Heavy Bags | Resin pellets, Fertilizer, Salt, Polymer granules (25kg-50kg bags). | Heavy Duty Seal: Uses thick polyethylene (PE) film. The machine forms the bag from a roll, fills it, and creates a heavy-duty seal capable of withstanding the weight without bursting during stacking. | |

| Valve Bag Packers | Cement, Grout, Fine Chemical Powders. | Dust Containment: The industry standard for fine powders. The bag is placed on a spout, and product is forced in via air or impeller. The internal pressure closes the valve automatically, minimizing dust leakage into the factory. | |

| Jerry Can / Pail Fillers | Motor oil, Paint, Adhesives (5L – 20L containers). | Anti-Drip & Cut-off: Viscous industrial fluids (like paint) require specialized nozzles that “suck back” or cut off cleanly to keep the pail rim clean for the lid application. | |

| 二次梱包 | Shrink Bundlers (Sleeve Wrappers) | Multipacks of motor oil bottles, brake fluid, or spray cans. | Stability: Instead of boxes, industrial retail items are often grouped in a “bullseye” shrink wrap tray. The machine must apply thick film to hold heavy bottles together securely during transport. |

End-of-Line Systems: The Universal Essentials

By the time the customer received their packaged products, the items had usually entered their container a bottle of shampoo, a can of tuna, or a bag of cement. It Is then imperative that the product is placed in a box, which is then placed on pallets. This task is the responsibility of the end-of-line (EOL) systems for consumer products. To ensure longevity, regular maintenance of these systems is crucial.

In contrast to the original packaging machinery we talked about, EOL equipment is mostly universal, Stacking a box, a robot needs not know what chemicals the interior product is; it just needs to know the carton’s weight and size. Such a universal approach permits standardized solutions to a multitude of varying weight and size. Such a universal approach permits standardized solutions to a multitude of various industries.

The next table identifies critical components of the mechanization utilized in practically all factories:

| マシンタイプ | Primary Function | Universal Application Logic |

| ラベリングマシン | Applies identifying stickers (barcodes, branding, ingredients) to containers or boxes. | Surface Agnostic: Whether the bottle is glass (beer) or plastic (shampoo), the physics of applying a pressure-sensitive label remains the same. The machine focuses on the surface geometry, not the content. |

| ケースパッカーズ | Groups individual units (e.g., 12 cans) and loads them into a master corrugated carton (RSC). | Dimension Driven: The machine’s inputs are strictly length, width, height, and weight. A case packer can handle boxes of pharmaceuticals just as easily as boxes of auto parts, provided the dimensions are within range. |

| パレタイザー | Stacks sealed cartons onto a pallet (wood or plastic) in a specific interlocking pattern for stability. | Logistics Standard: Pallet sizes (Euro-pallet, GMA) are standardized globally. A robotic arm (like ABB or Fanuc) uses the same gripper technology to stack 20kg boxes of flour as it does 20kg boxes of electronics. |

Beyond Specifications: A Strategic Selection Framework

Selecting packaging machinery is not merely a technical exercise of matching voltage and air consumption; it is a strategic business decision. For a manufacturer, the risk is not just buying a machine that doesn’t work, but buying a machine that becomes a bottleneck as the business grows.

Rather than looking at a simple spec sheet, experienced procurement officers evaluate equipment based on Long-Term Operational Viability to make an informed decision. Use the following strategic matrix to look beyond the price tag and assess the true value of a potential machine partner, considering factors like labor costs and ROI.

| Strategic Variable | The Manufacturer’s Insight |

| Adaptability vs. Rigidity | Prioritize Agility: For growing SMEs, avoid rigid single-format machines. Choose linear systems with tool-less adjustments to launch new SKUs without purchasing new capital assets. |

| Component Universality | Standardize Components: Ensure the machine uses global brands (e.g., Siemens, Schneider). You should be able to source spares locally in 24 hours, rather than waiting weeks for proprietary parts. |

| 総所有コスト | Value Over Price: “Cheap” machines often cost more in downtime and recalibration. Invest in Servo-driven architecture for digital precision, easier hygiene, and lower long-term operating costs. |

| Vendor Ecosystem | Verify Support: You are buying a partnership, not just metal. Require Factory Acceptance Tests (FAT) and real-time remote support to ensure a smooth launch and minimal disruption. |

Ready to Build Your Line?

Packaging machinery is an investment in your brand’s reputation. Whether you are launching a new line of protein powders or scaling up your canned food production, you need a partner who understands both the mechanics of the machine and the realities of your industry.

If you are looking for high-precision, customized canning or solid filling solutions that bridge the gap between SME agility and industrial reliability, レバパック is here to help. お問い合わせ today to discuss your product, and let’s engineer a solution that fits your factory floor perfectly.