Salah satu investasi paling signifikan yang dapat dilakukan perusahaan untuk memperluas operasi dan menjaga integritas produknya serta daya saingnya di pasar kontemporer adalah otomatisasi pengemasan. Salah satu solusi yang paling bervariasi dan umum digunakan adalah mesin pengemas kantong. Ini adalah peralatan yang menyediakan teknik canggih untuk mengemas berbagai produk ke dalam kantong yang fleksibel dan memenuhi persyaratan banyak industri agar efisien, andal, dan rapi. Panduan ini dimaksudkan untuk memberikan gambaran rinci tentang teknologi mesin pengisi kantong, konsep dasar, serta hal-hal penting yang perlu dipertimbangkan saat akuisisi, dan dimaksudkan untuk berfungsi sebagai alat strategis bagi pemilik bisnis, manajer pabrik, dan profesional pengadaan.

Apa yang dimaksud dengan Mesin Pengemas Kantong?

Mesin pengemas kantong adalah sistem elektromekanis yang digunakan untuk mengemas produk secara otomatis ke dalam kantong fleksibel yang telah dibentuk sebelumnya atau kantong yang terbuat dari gulungan film datar. Tujuan utamanya adalah untuk mengisi kantong secara tepat dengan jumlah produk tertentu dan kemudian menyegelnya secara efektif agar tetap aman dan bebas dari gangguan lingkungan, memperpanjang masa simpan, dan membuatnya siap untuk didistribusikan dan dijual.

Sangat dirancang untuk memenuhi berbagai jenis produk seperti bubuk (tepung, bubuk protein), butiran (kopi, makanan ringan, biji-bijian), cairan (saus, minuman, deterjen), dan benda padat (perangkat medis, perangkat keras kecil). Mesin pengisi kantong menggantikan tenaga kerja manual atau semi-manual, sehingga memberikan manfaat besar dalam hal kecepatan produksi, konsistensi pengemasan, dan kebersihan operasional. Mesin ini merupakan elemen pokok dari lini produksi modern, dan menghubungkan proses pembuatan produk dengan tampilan pasar utamanya.

Jenis Mesin Pengemas Kantong Dijelaskan

Pasar dapat dikategorikan dalam hal metode pengemasan kantong yang digunakan dalam membentuk, mengisi, dan menyegel kantong. Perbedaan ini sangat penting dalam pemilihan teknologi yang akan digunakan dalam aplikasi apa pun.

Mesin Formulir Isi-Segel Vertikal (VFFS)

Mesin FFS merakit kantong dari satu gulungan film datar dalam posisi vertikal, yang biasanya disebut sebagai segel pengisian formulir. Ini dimulai ketika film ditarik dari gulungan dan ditarik melalui tabung pembentuk yang menggulung film datar ke dalam tabung vertikal. Segel belakang kantong kemudian diproduksi oleh batang penyegel vertikal. Rahang penyegel horizontal kemudian membentuk segel bawah kantong pertama, dan pada saat yang sama membentuk segel atas kantong yang diisi sebelumnya di bawahnya. Produk kemudian dimasukkan ke dalam kantong dengan menjatuhkan pengisi (timbangan atau pengisi bertenaga auger) melalui tabung pembentuk. Langkah terakhir adalah penyegelan bagian atas melalui rahang penyegelan horizontal dan pemisahan kantong jadi yang jatuh pada konveyor. Barang curah, bubuk, cairan, dan produk butiran lainnya sangat efisien jika dikemas dengan menggunakan sistem VFFS.

Mesin Formulir Isi-Segel Horisontal (HFFS)

Mesin HFFS bekerja pada bidang horizontal dan membentuk kantong dari gulungan film dalam proses pengisian formulir horizontal. Film dimasukkan ke dalam mesin, dilipat, dan disegel pada tiga sisi untuk membuat kantong yang diposisikan untuk mengisi stasiun melalui pengindeksan. Perbedaan utamanya adalah arah gerakan horizontal dan kemungkinan untuk memindahkan produk yang tidak dapat diganti secara vertikal, seperti benda padat dan datar, seperti barang kering, perangkat keras, atau alat tes medis. Mesin HFFS biasanya digunakan untuk membuat kantong berdiri (Doypack) dan dapat menggabungkan elemen rumit seperti penutup ritsleting dan cerat dalam proses pembentukan.

Mesin Pengemas Kantong yang Sudah Jadi

Berbeda dengan sistem form-fill-seal, mesin pengemas kantong premade menggunakan kantong yang sudah dibuat dan siap digunakan. Mekanismenya digunakan untuk memilih salah satu kantong cepat di majalah kantong, menahannya, dan membukanya melalui mekanisme vakum atau semburan udara. Kantong yang terbuka kemudian akan dibawa ke stasiun pengisian di mana produk dikeluarkan. Setelah proses pengisian, operasi selanjutnya adalah stasiun penyegelan di mana batang dipanaskan untuk memberikan segel atas akhir. Mesin kantong yang sudah jadi sangat dihargai karena dapat memproses kantong berkualitas tinggi dan intensif grafis, termasuk fitur-fitur khusus seperti ritsleting tekan-ke-tutup, cerat, dan bentuk yang mungkin tidak mudah diproduksi secara in-line. Mesin ini tersedia dalam dua konfigurasi utama:

- Mesin Putar: Gripper yang menahan kantong berada pada korsel berputar yang bergerak dalam pola melingkar melalui berbagai stasiun (membuka, mengisi, dan menyegel). Mesin ini biasanya lebih cepat dan lebih tahan lama, serta dapat menangani laju produksi yang tinggi dan output yang besar.

- Mesin In-line: Pada mesin ini, kantong berada dalam garis lurus, bergerak melalui berbagai stasiun. Sistem ini relatif tidak terlalu rumit dan mungkin lebih ringkas; oleh karena itu, sistem ini biasanya cocok untuk fasilitas dengan keterbatasan ruang atau dengan persyaratan produksi yang lebih sedikit.

Jika Anda ingin tahu lebih banyak tentang perbedaan antara mesin putar dan mesin inline, bacalah artikel ini: Mesin Pengemas Linear Vs Mesin Pengemas Putar: Bagaimana Cara Memilih yang Tepat?

Bagaimana Cara Kerja Mesin Pengemas Kantong?

Mekanisme setiap jenis mesin berbeda, tetapi urutan kerjanya sama dan logis. Sebagai contoh mesin rotary pouch yang sudah jadi, seluruh proses pengisian dibagi ke dalam serangkaian langkah:

- Pemuatan Kantong: Operator kemudian memasukkan setumpuk kantong yang telah dibuat sebelumnya ke dalam majalah kantong yang mudah diakses yang terletak di bagian depan mesin. Stasiun pemuatan kantong yang cepat akan memberikan pengumpanan yang nyaman dengan waktu yang minimum.

- Pengumpanan dan Pencengkeraman Kantong: Lengan penanganan kantong dengan cangkir hisap mengambil kantong individual dan memindahkannya ke sepasang gripper yang akan menahannya dengan kuat saat bergerak melalui mesin unik ini.

- Pencetakan/Emboss (Opsional): Langkah opsional di mana kode tanggal, nomor lot, atau data variabel lainnya dapat dicetak atau diembos ke kantong.

- Pembukaan dan Deteksi Kantong: Gripper menarik bagian bawah kantong, dan bagian atas dibuka dengan pembuka ritsleting otomatis atau semburan udara. Sebuah sensor memastikan bahwa kantong terbuka dan siap untuk diisi. Jika kantong tidak terbuka, siklus pengisian pada stasiun itu dilewati untuk menghindari tumpahan produk.

- Pengisian Produk: Kantung terbuka ditempatkan di bawah perangkat pengisian (misalnya, timbangan multi-kepala untuk mengisi produk padat, mesin pengisi auger untuk mengisi bubuk, atau pompa piston untuk mengisi produk cair). Produk dikeluarkan dengan baik di dalam kantong.

- Penyegelan dan Deflasi: Kantong masuk ke stasiun penyegelan. Suatu mekanisme dapat digunakan untuk meremas kantong secara lembut sebelum menyegelnya. Tepi atas kantong kemudian disegel oleh batang segel yang dipanaskan, yang memberikan tekanan dan panas dan dengan demikian menciptakan segel kedap udara.

- Pendinginan dan Pembuangan: Setelah penyegelan, mungkin terdapat bilah pendingin yang dapat menekan segel untuk menyempurnakannya. Gripper kemudian membuka kantong yang sudah jadi, yang dikeluarkan ke konveyor untuk diangkut ke pengemasan wadah atau sistem pengemasan sekunder.

Fitur Utama yang Perlu Dipertimbangkan dalam Kemasan Kantong

Saat memilih mesin pengemas kantong, penting untuk mempertimbangkan beberapa fitur utama yang secara langsung memengaruhi efisiensi dan kualitas produk.

Ukuran Kantong: Hal ini untuk memastikan bahwa mesin mendukung berbagai ukuran kantong yang sesuai dengan kebutuhan pengemasan Anda. Mesin yang dapat menangani berbagai jenis kantong, termasuk kantong blok bawah, buhul samping, dan kantong ritsleting saku, juga memberikan fleksibilitas yang memungkinkan mesin mengemas berbagai produk.

Bahan dan Daya Tahan: Daya tahan dan perawatan yang mudah tergantung pada bahan mesin pengemas kantong. Baja tahan karat adalah yang paling umum karena tahan terhadap korosi dan membutuhkan metode pembersihan yang sederhana, serta tahan lama. Inilah sebabnya mengapa bahan ini ideal untuk industri seperti makanan dan kemasan medis, di mana kebersihan adalah prioritas utama.

Kecepatan dan Efisiensi: Mesin yang memiliki kecepatan produksi tinggi sangat ideal untuk bisnis berskala besar karena mesin ini membuat pengemasan menjadi cepat dan akurat. Sistem konveyor, sistem pengisian kantong otomatis, dan konveyor keluar terintegrasi dapat membantu merampingkan alur kerja apa pun, bahkan dalam pengaturan produksi dengan permintaan tinggi seperti pengemasan makanan ringan atau makanan hewan.

Otomatisasi: Mesin yang sepenuhnya otomatis berpotensi mengurangi kebutuhan tenaga kerja dan meningkatkan kecepatan proses pengemasan. Sensor pengisian dan pembuka ritsleting bersifat otomatis, yang berarti dapat mengurangi kesalahan manusia, meningkatkan konsistensi, dan membuat operasi lebih cepat.

Jenis Kantong Populer untuk Mesin Pengemasan

Fleksibilitas mesin pengemas kantong hanya dapat disamai oleh keragaman gaya kantong yang akan diakomodasi oleh mesin, masing-masing dengan manfaat unik untuk perlindungan produk dan promosi produk.

- Kantung Bantal: Ini adalah kantong sederhana dan murah yang menggunakan satu lapisan film, dengan segel di bagian atas, bawah, dan segel sirip vertikal di bagian dasarnya. Umumnya digunakan sebagai camilan, seperti keripik atau kerupuk.

- Kantung Berdiri (Doypack): Kantong ini memiliki buhul bawah, yang memungkinkannya untuk berdiri di rak, sehingga memberikan visibilitas ritel yang baik dan penampilan yang berbeda. Umumnya digunakan dalam berbagai produk, termasuk granola dan sabun cair, dan sering kali dilengkapi dengan ritsleting atau cerat yang dapat ditutup kembali.

- Kantong Segel Tiga Sisi: Kantung pipih yang disegel pada tiga sisi, dengan satu sisi yang dibiarkan terbuka untuk mengisi kantung. Kantong ini hemat biaya dan cocok untuk aplikasi sekali saji, misalnya campuran minuman bubuk atau dendeng.

- Tas Gusset: Kantong ini memiliki sambungan di semua sisinya dan bentuknya lebih mirip kotak saat penuh. Kantong ini banyak digunakan pada produk seperti biji kopi dan tepung, dengan sistem yang sepenuhnya otomatis sehingga dapat memanfaatkan ruang rak secara maksimal.

Industri yang Mengambil Manfaat dari Kemasan Kantong

Mesin pengemas kantong umum digunakan di banyak industri dengan kebutuhan pengemasan yang berbeda-beda. Berikut adalah beberapa industri utama yang dapat memanfaatkan solusi pengemasan serbaguna ini:

- Makanan dan Minuman

Kemasan kantong sebagian besar digunakan dalam industri makanan dan minuman. Kantong dapat memainkan peran penting dalam menjaga produk tetap segar, bertindak sebagai penghalang terhadap oksigen dan kelembapan, dan juga mudah digunakan oleh konsumen. Mesin kantong sangat efisien dalam mengemas makanan ringan dan minuman serta makanan siap saji dan makanan kering, memberikan kenyamanan dan kualitas.

- Obat-obatan dan Nutraceuticals

Kemasan kantong memainkan peran penting dalam industri farmasi dan nutraceutical di mana presisi, kemandulan, dan kepatuhan terhadap peraturan yang ketat merupakan faktor penting. Kemasan anti-rusak tersedia dengan menggunakan mesin kantong, yang cocok untuk serbuk, pil, dan perangkat medis. Dikombinasikan dengan mesin pengisi tambahan seperti timbangan bersih linier, mesin ini mencapai keakuratan takaran yang diinginkan sesuai standar industri.

- Bahan Kimia dan Barang Rumah Tangga

Industri barang rumah tangga dan industri kimia membutuhkan pengemasan yang lebih berfokus pada keamanan dan daya tahan. Mesin pengemas kantong dapat digunakan untuk mengemas produk dalam kantong keras seperti deterjen, pupuk, dan pelarut, yang ditangani dengan aman. Sebagian besar mesin memiliki penutup khusus untuk menghindari tumpahan dan pengeluaran yang mudah.

- Makanan Hewan Peliharaan

Kemasan kantong bermanfaat bagi industri makanan hewan peliharaan, baik makanan basah maupun kering. Dalam industri ini, mesin harus dapat mendukung ukuran kantong yang lebih besar dan mampu menjaga kesegaran produk serta membuat segel yang kokoh untuk mencegah bau. Mesin semacam itu diharapkan dapat memenuhi tantangan pengemasan produk berkualitas seperti mengunyah hewan peliharaan dan produk makanan hewan khusus lainnya.

Faktor yang Mempengaruhi Harga Mesin Pengemas Kantong

The biaya mesin pengemas kantong mungkin sangat berbeda tergantung pada sejumlah faktor. Faktor-faktor tersebut adalah jenis mesin, kecepatan, bahan, dan konstruksi yang digunakan dalam mesin, serta fungsi lain yang menambah total investasi. Ini adalah faktor utama yang berdampak pada biaya:

- Jenis dan Konfigurasi Mesin: Mesin kantong yang dibuat sebelumnya dengan mesin rotary biasanya lebih mahal daripada mesin VFFS (Vertical Form-Fill-Seal) atau mesin in-line, karena sistem mekanisnya yang lebih rumit dan kecepatannya yang lebih besar. Mesin rotary dapat berharga antara $50.000 dan $150.000, sedangkan mesin VFFS dan in-line berkisar antara $15.000 dan $60.000.

- Kecepatan dan Otomatisasi: Mesin yang memiliki kecepatan yang lebih tinggi dan sistem otomatisasi yang lebih banyak harganya mahal. Mesin yang sangat otomatis yang mungkin melibatkan input manusia minimal cenderung menarik harga tinggi. Tergantung pada fitur-fiturnya, sistem pengemasan kantong berkecepatan tinggi yang sepenuhnya otomatis akan menelan biaya antara $60.000 dan $150.000.

- Bahan Konstruksi: Bahan yang digunakan dalam konstruksi juga dapat mempengaruhi biaya. Mesin yang terbuat dari baja tahan karat food grade lebih tahan lama dan lebih bersih, tetapi cenderung lebih mahal daripada mesin yang memiliki rangka baja yang dicat. Mesin baja tahan karat akan meningkatkan total biaya sebesar 10-30%.

- Sistem Pengisian Terpadu: Jenis sistem pengisian yang dipasang di mesin, misalnya timbangan multi-kepala, dapat meningkatkan biaya secara substansial. Pengisi seperti ini sering kali berkontribusi secara signifikan terhadap biaya akhir, yang dapat mencapai $10.000 hingga $40.000 sebelum kemampuannya dipertimbangkan.

- Fitur Kustomisasi dan Opsional: Fitur opsional seperti sistem pembilasan gas untuk memungkinkan pengemasan atmosfer yang dimodifikasi (MAP), kode tanggal, aplikator ritsleting, dan sistem penyegelan canggih, semuanya berperan dalam keseluruhan biaya. Biaya model bisa naik dengan selisih $2.000 hingga $30.000, tergantung pada fitur yang disertakan.

Cara Memilih Mesin Pengemas Kantong yang Tepat

Sangat penting untuk memilih mesin pengemas kantong yang tepat untuk mencapai efisiensi dalam jangka pendek dan skalabilitas dalam jangka panjang. Prosedur yang sistematis dan bertahap akan memastikan Anda memilih mesin yang sesuai dengan kebutuhan produksi saat ini dan fleksibel untuk ekspansi di masa mendatang.

- Menganalisis Produk: Pertama, analisis produk Anda. Apakah berbentuk bubuk, cair, atau padat? Apakah produk tersebut sensitif, berpasir, atau korosif? Sebagai contoh, cairan mungkin memerlukan solusi penyegelan khusus untuk menghindari kebocoran, sedangkan bubuk mungkin memerlukan pengisi bubuk auger untuk mengisinya dengan cara yang terkendali.

- Tentukan Paket: Tuliskan jenis kantong, ukuran kantong, dan bahan yang Anda inginkan. Pertimbangkan jenis stand-up pouch, flat pouch, atau doypack yang Anda butuhkan. Film atau bahan kantong juga harus diuji untuk dapat bekerja secara optimal dengan mesin Anda. Hal ini akan mencegah terjadinya komplikasi dalam proses produksi.

- Menetapkan Kebutuhan Produksi: Berapa banyak kantong per menit yang Anda butuhkan? Selain itu, tentukan jumlah jam mesin akan beroperasi per hari. Ketika Anda memproyeksikan pertumbuhan atau permintaan yang lebih besar, pilih mesin yang dapat mengatasi peningkatan itu, baik dalam kecepatan atau dengan menambahkan modul.

- Mengevaluasi Anggaran dan ROI: Pertimbangkan total biaya kepemilikan (TCO). Hal ini tidak hanya mempertimbangkan harga pembelian tetapi juga biaya pemasangan, pelatihan, pemeliharaan, dan penggantian suku cadang dalam jangka panjang. Mesin yang lebih mahal mungkin bukan investasi yang baik, tetapi lebih baik dalam hal keandalan, efisiensi, dan kemampuan untuk menangani volume yang lebih tinggi dengan biaya jangka panjang yang lebih rendah.

- Menilai Kendala Fasilitas: Sebelum membuat keputusan, ukurlah ketersediaan kaki persegi ruang lantai. Periksa apakah utilitas seperti udara bertekanan, daya listrik, dan air (jika ada) sudah tersedia dan kompatibel dengan kebutuhan mesin.

- Dokter Hewan Pemasok Potensial: Teliti dan selidiki pemasok berdasarkan reputasi dan pengalaman industri, serta kualitas layanan pelanggan dan jaringan dukungan mereka. Pastikan mereka menyediakan layanan purna jual yang baik, seperti ketersediaan teknisi perbaikan lokal, suku cadang, dan layanan. Sebaiknya Anda meminta demonstrasi produk atau mengunjungi pelanggan untuk memeriksa mesin yang sedang beroperasi.

5 Produsen Mesin Pengemas Kantong Teratas

Pasar mesin pengemas kantong di seluruh dunia memiliki banyak produsen terkenal. Meskipun tidak praktis untuk mencantumkan semuanya, beberapa perusahaan terkenal dalam hal teknologi dan kehadirannya di pasar. Berikut ini adalah lima pemain industri secara rinci.

#1 Levapack

Peringkat Rekomendasi: ☆☆☆☆

Tahun Pendirian: 2008

Lokasi: Guangdong, Tiongkok

Produk Utama: Mesin pengemas kantong yang sudah jadi, mesin pengalengan.

Deskripsi Spesifik:

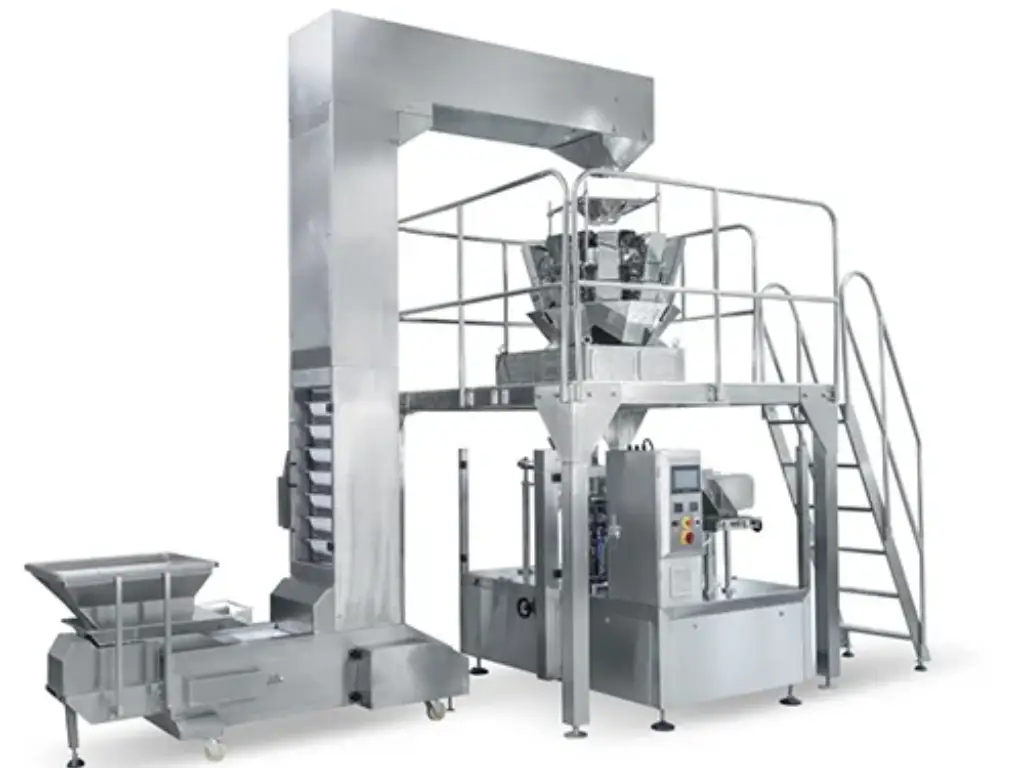

Levapack telah memposisikan dirinya sebagai produsen khusus mesin pengemas kantong yang sudah jadi sejak awal. Perusahaan ini berbasis di pusat manufaktur China dan dilengkapi dengan keahlian teknik lebih dari 18 tahun untuk menyediakan solusi pengemasan berkualitas tinggi dan dapat disesuaikan untuk klien internasionalnya. Levapack terutama berfokus pada mesin yang bekerja dengan kantong yang telah dibentuk sebelumnya dan memiliki model yang secara khusus disesuaikan dengan produk granular, bubuk, dan cairan. Spesialisasi ini akan memungkinkan klien untuk memiliki peralatan yang sangat disesuaikan dengan karakteristik produk mereka.

Faktor pembeda utama dari Levapack adalah bahwa kami menawarkan layanan menyeluruh. Mesin mereka dicirikan oleh tingkat otomatisasi yang tinggi, dengan sistem kontrol PLC + POD yang canggih sehingga sangat mudah dioperasikan, dan cepat dalam mengubah ukuran kantong. Perusahaan ini berfokus pada solusi manufaktur langsung, sebuah fitur yang memungkinkan mereka menyesuaikan seluruh sistem pengemasan dengan kebutuhan khusus proses produksi, seperti integrasi timbangan atau penggunaan teknik penyegelan tertentu. Melalui desain yang hemat biaya, efisien, dan higienis yang dibuat dengan menggunakan bahan tahan korosi, Levapack menawarkan proposisi nilai yang kuat bagi produsen di industri makanan, minuman, dan kimia yang ingin meningkatkan produktivitas pengemasan mereka.

Teknologi Syntegon #2

Peringkat Rekomendasi: ☆☆☆☆☆

Tahun Pendirian: 2020 (sebelumnya bernama Bosch Packaging Technology, dengan pengalaman lebih dari 150 tahun)

Lokasi: Waiblingen, Jerman

Produk Utama: Mesin segel bentuk-isi vertikal dan horizontal, teknologi proses.

Deskripsi Spesifik:

Syntegon, yang sebelumnya bernama Bosch Packaging Technology, memiliki sejarah keahlian teknik dalam industri pengemasan. Berbasis di Jerman, Syntegon adalah perusahaan yang sangat mapan dengan sejarah panjang dalam memproduksi sistem yang sangat andal dan dirancang dengan baik yang digunakan dalam industri makanan dan farmasi global, dan dengan demikian, merupakan mitra yang sangat baik bagi perusahaan multinasional. Perusahaan ini memiliki lini produk inti yang luas yang terdiri dari mesin VFFS dan HFFS, yang terkenal dengan kecepatan tinggi, presisi, dan desain struktural yang tahan lama, sehingga mampu menangani berbagai jenis film dan sensitivitas produk.

Mesin Syntegon merupakan solusi menyeluruh untuk pengemasan, yang biasanya mencakup seluruh lini produksi dan pengemasan akhir. Pendekatan gabungan ini sangat berharga bagi organisasi bisnis yang membutuhkan pendekatan satu atap yang efektif untuk masalah pengemasan yang kompleks. Salah satu misi Syntegon adalah komitmennya yang berkelanjutan terhadap keberlanjutan dan desain yang cerdas, di mana sistem dikembangkan untuk meminimalkan pemborosan bahan dan energi. Mesin mereka terkenal cepat beroperasi, yang merupakan fitur penting dari industri apa pun yang membutuhkan hasil maksimum.

#3 Paxiom Group (Sistem WeighPack)

Peringkat Rekomendasi: ☆☆☆☆☆

Tahun Pendirian: 1991

Lokasi: Montreal, Kanada (Kehadiran global)

Produk Utama: Mesin pengisian kantong yang sudah jadi, sistem VFFS dan HFFS, timbangan.

Deskripsi Spesifik:

Paxiom Group, melalui merek-merek utamanya seperti WeighPack Systems, telah menjadi pemain terdepan dalam industri otomasi pengemasan sejak didirikan pada tahun 1991. Paxiom telah mengembangkan jaringan internasional dengan lokasi strategisnya di Montreal, menawarkan layanan terintegrasi kepada kliennya untuk bisnis dengan berbagai ukuran. Perusahaan ini terkenal, terutama dalam lini Swifty Bagger dari mesin pengisian kantong yang sudah jadi, yang dirancang agar serbaguna dan berkinerja tinggi. Inti dari penawaran Paxiom adalah kebutuhan untuk memenuhi berbagai persyaratan produksi, dan sistem dirancang untuk menangani ukuran kantong yang besar dan ringkas.

Model khusus mereka meliputi Swifty Bagger Box Gusset, yang dirancang untuk menyegel kantong sisi buhul dengan buhul kotak untuk menciptakan tampilan yang unik. Dalam kasus aplikasi yang kompleks, model muatan samping Swifty Bagger memungkinkan produk dimuat ke arah tertentu, sedangkan mesin pengisian kantong Swifty Junior dapat digunakan melalui otomatisasi yang kuat saat melakukan peningkatan. Pengoperasiannya disederhanakan dengan layar sentuh berwarna dan fungsi lainnya, seperti perangkat pembuka ritsleting otomatis. Peralatan pasca-pengisian, seperti pengocok kantong, digunakan untuk meratakan produk. Terakhir, Paxiom adalah toko serba ada yang menawarkan solusi hilir siap pakai, dengan kemampuan untuk berintegrasi dengan timbangan periksa seperti timbangan periksa WeightCheq untuk memberikan jaminan kualitas.

#4 Coesia Group (Volpak dan Mespack)

Peringkat Rekomendasi: ☆☆☆☆

Tahun Pendirian: 1923 (Coesia Group)

Lokasi: Bologna, Italia

Produk Utama: Mesin horizontal form-fill-seal (HFFS) untuk pengemasan fleksibel.

Deskripsi Spesifik:

Coesia Group, dengan merek Volpak dan Mespack, adalah pemain terkemuka di pasar HFFS. Dengan sejarah industri yang kaya di Eropa, Coesia telah membangun kehadiran yang kuat di dunia dengan menekankan solusi pengemasan berkualitas tinggi dan sangat fleksibel. Grup ini memiliki merek-merek terkemuka di industri barang konsumsi, kimia, dan makanan sebagai pemasok pilihannya, terutama yang menggunakan kantong berdiri dan cerat. Inti dari lini produk Coesia adalah sistem HFFS mereka yang canggih, yang unggul dalam menciptakan kantong fleksibel yang kompleks dan berkualitas tinggi melalui penggunaan gulungan film.

Mesin semacam itu dipuji karena mampu menggabungkan fitur-fitur seperti cerat, tutup, dan ritsleting dalam satu lini, menawarkan solusi menyeluruh untuk produk yang menginginkan kenyamanan konsumen dan branding yang canggih. Fitur ini memberikan nilai jual yang unik bagi perusahaan yang ingin membedakan produknya. Selain itu, Coesia adalah perusahaan pertama yang mengembangkan sistem yang dapat bekerja dengan bahan kemasan yang berkelanjutan dan dapat didaur ulang, yang menggarisbawahi tanggung jawab lingkungan yang tinggi dan membantu Coesia untuk menjadi perusahaan terdepan dalam teknologi pengemasan yang fleksibel.

#5 Viking Masek

Peringkat Rekomendasi: ☆☆☆☆

Tahun Pendirian: 2004

Lokasi: Oostburg, Wisconsin, Amerika Serikat

Produk Utama: Mesin Vertical Form-Fill-Seal (VFFS), mesin stick pack dan sachet.

Deskripsi Spesifik:

Viking Masek adalah produsen sistem pengemasan otomatis terkemuka di AS yang dengan cepat mengembangkan reputasi dalam menyediakan sistem pengemasan otomatis berkinerja tinggi dan tahan lama. Perusahaan ini berlokasi strategis di Wisconsin dan menawarkan solusi yang kuat dan layanan penuh untuk berbagai industri, seperti makanan ringan, kopi, keju, dan suplemen nutrisi. Mereka berspesialisasi terutama dalam teknologi Vertical Form-Fill-Seal (VFFS), dan mesin yang mereka tawarkan diakui dapat diandalkan, mudah digunakan, dan serbaguna dalam mengisi berbagai macam produk dan film kemasan.

Karakteristik penting lainnya dari Viking Masek adalah tingkat layanan pelanggan yang tinggi dan pendekatan yang berorientasi pada kemitraan jangka panjang. Mesin mereka dirancang sedemikian rupa sehingga tahan lama dan didukung oleh jaringan servis yang dapat dihubungi dengan segera, dan ini mengurangi waktu mesin tidak berfungsi. Selain sistem VFFS mereka yang populer, bisnis ini juga bekerja pada mesin stick pack dan sachet kecil, yang menjadikannya solusi yang nyaman untuk bisnis yang menangani pengemasan satu porsi. Konstruksi yang kokoh dan tahan lama yang dikombinasikan dengan kontrol modern yang mudah digunakan dan dedikasi terhadap layanan menjadikan Viking Masek sebagai sumber otomatisasi pengemasan yang dapat diandalkan di area produksi yang paling menuntut.