Dalam dunia pengemasan industri, kecepatan dan konsistensi mekanisme pembatasan sangat penting untuk integritas produk, keamanan, dan citra merek. Pemilihan mesin capping merupakan langkah penting yang harus dilakukan oleh produsen yang bekerja dalam volume besar, karena secara langsung memengaruhi tingkat keluaran, biaya pengoperasian mesin, dan kontrol kualitas. Mesin rotary capping telah muncul sebagai teknologi pilihan dalam lingkungan produksi berkecepatan tinggi dan menuntut.

Buku panduan ini menawarkan analisis mendalam tentang mesin rotary capping yang ditargetkan untuk manajer produksi, insinyur pengemasan, dan pengambil keputusan. Dalam pembahasannya, kami akan mengulas prinsip-prinsip yang menjadi dasar mesin, karakteristik teknisnya, berbagai kegunaannya, serta kriteria utama yang diperlukan untuk memilih mesin yang sesuai dengan kebutuhan operasional Anda.

Apa yang dimaksud dengan Mesin Pembatas Rotari?

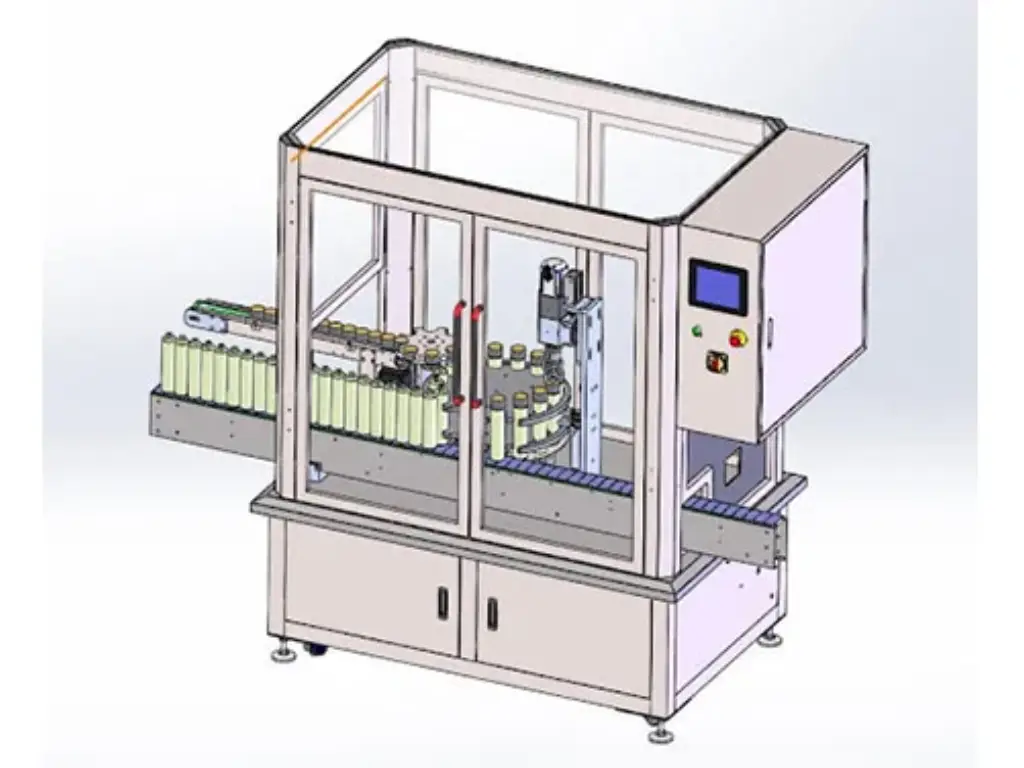

Mesin rotary capping adalah mesin pengemasan otomatis yang menerapkan dan mengencangkan tutup pada wadah dalam proses yang kontinu dan berkecepatan tinggi. Fitur utamanya adalah bahwa mesin ini terdiri dari menara berputar, atau korsel, yang membawa beberapa kepala penutup. Wadah dimasukkan ke dalam mesin dan diatur waktunya agar sesuai dengan turret yang berputar, ditutup dalam satu putaran, dan dikeluarkan kembali ke jalur produksi.

Filosofi kerja utamanya adalah gerakan konstan. Tidak seperti sistem lain, yang mengharuskan wadah dan kepala penutup berhenti untuk melakukan tindakan penutupan ini, rotary capper melakukan seluruh proses karena wadah dan kepala penutup bergerak secara kontinu dan lancar. Ini adalah desain utamanya yang membuatnya cepat dan efisien.

Untuk mendapatkan gambaran yang lebih baik mengenai lokasinya di pasar, akan sangat membantu untuk mendefinisikannya dibandingkan dengan jenis capper lain yang sering digunakan:

- Mesin Pembatasan Inline: Sistem ini memasang tutup pada wadah yang ditransfer dalam garis lurus pada konveyor. Penutupan biasanya dilakukan dengan set roda atau sabuk yang berputar yang menyegel tutup saat berputar. Dengan aplikasi yang baik, sistem ini lambat dibandingkan dengan sistem putar.

- Mesin Pembatas Gerakan Terputus-putus: Ini biasanya merupakan mesin chuck satu kepala yang akan menghentikan setiap kontainer di bawah stasiun penutup dan memasang serta mengencangkan penutupnya, lalu memindahkan kontainer. Siklus start-stop seperti itu berarti bahwa throughput secara inheren terbatas dan umumnya lebih sesuai di lini produksi berkecepatan rendah atau di mana penutupan yang sangat spesifik dan kompleks diperlukan.

Rotary capper, dengan menghilangkan jeda ini, direkayasa secara khusus untuk operasi di mana memaksimalkan output tanpa mengorbankan kualitas adalah tujuan utama.

Cara Kerja Pembatasan Putar: Penjelasan Gerakan Berkelanjutan

Hasil produksi yang tinggi dari mesin rotary capping secara langsung dikaitkan dengan desain gerakan kontinu. Kunci untuk mengenali efisiensi proses ini adalah dengan memahaminya. Aliran operasi adalah tarian mekanis yang diatur waktunya dengan baik yang ditujukan untuk mencapai kecepatan dan keseragaman maksimum.

- Pengumpanan Kontainer: Wadah dikirim pada sabuk konveyor keluar dan diarahkan ke roda bintang pemakanan. Ini adalah komponen berbentuk bintang dan dikerjakan dengan mesin dengan kantong yang pas dengan diameter kontainer. Ini mengunci setiap kontainer dan secara akurat mengatur waktu masuknya ke dalam menara berputar utama.

- Sinkronisasi dengan Turret: Roda bintang pemakanan yang berputar menyebabkan setiap kontainer ditempatkan di atas platform tepat di bawah kepala penutup terbuka pada turret utama. Pada titik ini, kontainer berayun dalam gerakan melingkar dalam sinkronisasi penuh dengan rotasi turret.

- Aplikasi Tutup dan Penyegelan: Hal ini dilakukan ketika wadah berputar dengan turret, dan sistem pengiriman tutup otomatis diletakkan pada pembukaan wadah. Kepala penutup di atasnya segera bergerak ke bawah dan menahan tutup dan memberikan tekanan/torsi yang diperlukan untuk menutupnya. Semua ini (penempatan tutup dan pengencangan berikutnya) dilakukan saat turret masih berputar.

- Pembuangan Kontainer: Pada akhir siklus capping, wadah pada tahap ini tertutup rapat, dan mencapai titik pembuangan jalur melingkar. Roda bintang pelepasan dengan lembut mengendapkannya kembali ke konveyor utama, dan berlanjut ke bagian berikutnya dari jalur pengemasan (misalnya, pengemas wadah atau pelabelan).

Aliran yang lancar dan kontinu ini berarti bahwa beberapa wadah ditutup secara bersamaan pada titik yang berbeda dari rotasi turret. Mesin dengan 12 kepala, misalnya, melakukan 12 operasi pembatasan per satu putaran. Perbedaan desain yang mendasar inilah yang memungkinkan rotary cappers mencapai kecepatan beberapa ratus botol per menit (BPM), tingkat efisiensi yang tidak dapat dicapai oleh sistem yang terputus-putus atau sebagian besar sistem yang sebaris.

Jenis Kepala Penutup Putar dan Tutup yang Kompatibel

Keuntungan terbesar dari mesin rotary capping adalah mesin ini dapat disesuaikan agar sesuai dengan beberapa bentuk kemasan yang berbeda dengan menggunakan berbagai jenis kepala penutup. Semua jenis kepala dirancang agar sesuai dengan jenis penutupan tertentu untuk menjamin bahwa botol ditutup dengan torsi, konsistensi, dan integritas yang tepat. Berdasarkan perbedaan antara kepala penutup, produsen dapat memilih solusi yang tepat agar sesuai dengan lini produk mereka dan memastikan kualitas dan kinerja.

| Jenis Kepala Pembatasan | Gaya Topi yang Kompatibel | Industri Umum | Keuntungan Utama |

| Kepala Tutup Sekrup | Tutup sekrup berulir plastik atau logam | Minuman, toples makanan, obat-obatan, dan bahan kimia rumah tangga | Kontrol torsi yang tepat untuk penyegelan yang konsisten |

| Kepala Tutup Jepret | Penutupan yang dapat ditekan atau dipasang dengan mudah | Perawatan pribadi, kosmetik, dan produk makanan tertentu | Aplikasi sederhana berkecepatan tinggi dengan pembukaan yang ramah konsumen |

| Kepala Pompa & Penyemprot | Pompa losion, penyemprot pemicu, penyemprot kabut halus | Kosmetik, produk pembersih, dan perawatan kesehatan | Penanganan yang aman untuk penutupan yang tidak beraturan, orientasi yang akurat |

| Kepala ROPP | Tutup anti-pencurian dari aluminium roll-on | Anggur, minuman beralkohol, dan obat-obatan | Penyegelan anti rusak dengan ulir yang dibentuk dan tali pengaman |

| Kepala Tutup Lug Cap | Tutup pelintir logam (lug) | Saus, selai, bumbu, produk makanan isi panas | Torsi seragam untuk penyegelan vakum dan keamanan produk |

- Kepala Tutup Sekrup (Penutup Berulir)

Kepala tutup ulir adalah pekerja keras untuk lini minuman dan farmasi berkecepatan tinggi. Dilengkapi dengan kontrol torsi yang dikontrol servo, mereka memastikan setiap botol air PET dan botol obat kaca mendapatkan segel yang sama, mencegah kebocoran air atau obat dan memastikan kepatuhan terhadap peraturan. Pada minuman berkarbonasi, torsi harus tepat untuk menahan tekanan internal tanpa merusak ulir.

- Kepala Tutup Jepret (Penutup yang Dapat Dipasang dengan Tekan)

Kepala jepret mengerahkan gaya ke bawah dan oleh karena itu sesuai untuk digunakan pada kosmetik dan produk perawatan pribadi yang mengutamakan kenyamanan. Sebagai contoh, kemasan lotion atau krim bervolume tinggi dapat menggunakan snap head yang memungkinkan antrean dijalankan dengan kecepatan ratusan unit per menit dengan nuansa klik untuk menutup yang konsisten bagi konsumen.

- Kepala Pompa dan Penyemprot

Ini adalah penutup khusus yang menangani penutupan yang tidak teratur dan halus seperti semprotan pemicu atau pompa lotion. Dalam lini produk pembersih, seperti kepala pompa memiliki gripper bermuatan pegas untuk mengarahkan dan mengamankan penyemprot selama penutupan untuk mencegah ketidaksejajaran, yang dapat membuat pelatuk tidak dapat digunakan. Hal ini dapat memberikan kinerja yang dapat diandalkan di pasar yang mengutamakan keselamatan konsumen dan kemudahan penggunaan.

- Kepala ROPP (Penutup Anti Pencurian yang Dapat Digulung)

Pembotolan anggur dan minuman beralkohol tidak dapat dilakukan tanpa kepala OPP. Kepala melakukan lebih dari sekadar memasang tutup: kepala menggulung benang dan pita anti rusak ke dalam penutup aluminium, membentuk segel yang aman yang dikombinasikan dengan peringatan yang terlihat jika terjadi kerusakan. Dalam obat-obatan, hal ini berguna bagi produsen karena memungkinkan mereka untuk mematuhi undang-undang anti-pemalsuan yang ketat.

- Kepala Tutup Lug Cap (Penutup yang Dapat Diputar)

Lug head sangat populer di industri makanan ketika produk perlu disegel secara vakum, seperti saus, selai, dan produk isi panas. Saat menutup, mesin mengerahkan kekuatan yang sama dengan tutup sehingga pas di lugs stoples kaca dan mempertahankan kesegaran bahkan setelah menjalani proses termal. Salah satu alasan mengapa kepala penutup lug digunakan sebagai standar di seluruh dunia untuk makanan yang stabil di rak adalah keandalannya.

Fitur Utama yang Membedakan Mesin Top Capping

Meskipun setiap mesin rotary capping dijalankan dalam gerakan kontinu, mesin premium dicirikan oleh teknologi canggih yang meningkatkan presisi, keandalan, dan keramahan pengguna. Ini adalah karakteristik pembeda yang penting ketika membandingkan berbagai model.

- Kecepatan Tinggi & Presisi Tinggi: Dua nilai jual yang paling penting ini berjalan seiring. Konstruksi mekanisnya mampu beroperasi pada kecepatan tinggi, tetapi sistem kontrollah yang memastikan keakuratan pada kecepatan tinggi. Lihatlah konstruksi kokoh yang bebas getaran dan stabil selama pengoperasian.

- Kontrol Torsi Berbasis Servo: Ini adalah teknologi capping yang terbaik. Berbeda dengan cengkeraman magnetik atau mekanis konvensional, yang dapat aus dan menjadi kurang akurat seiring berjalannya waktu, motor servo memiliki kontrol torsi yang sangat presisi dan dapat diulang. Nilai torsi dapat disesuaikan secara digital oleh setiap kepala capping menggunakan motor servo. Hal ini menghilangkan pengencangan yang berlebihan (yang dapat merusak tutup atau wadah) dan pengencangan yang kurang (yang dapat menyebabkan kebocoran dan pembusukan produk).

- PLC + Kontrol HMI: Fungsi mesin modern diatur oleh Programmable Logic Controller (PLC), otak tingkat industri di tempat kejadian. PLC diprogram oleh operator yang berkomunikasi dengan PLC menggunakan Human-Machine Interface (HMI), yang biasanya berupa layar sentuh berwarna. Ini adalah kombinasi yang menawarkan manfaat besar.

- Manajemen Resep: Menyimpan pengaturan (torsi, kecepatan, tinggi wadah) dari berbagai produk. Pergantian resep semudah memilih resep baru di layar.

- Diagnostik Waktu Nyata: Sistem ini dapat memeriksa kinerjanya, memberikan pesan peringatan kepada operator mengenai tutup yang hilang atau penerapan torsi yang tidak tepat.

- Kemudahan Penggunaan: Antarmuka pengguna grafis membuat alat berat mudah dioperasikan dan menurunkan tingkat pengetahuan teknis khusus yang diperlukan untuk mengoperasikan alat berat.

- Deteksi "Tanpa Botol, Tanpa Tutup": Sensor terintegrasi yang dapat mendeteksi keberadaan wadah dan, oleh karena itu, tidak akan melepaskan tutupnya. Fitur kecil namun penting ini menghindari pemborosan tutup dan menjaga mesin tetap bersih dari tutup yang jatuh, serta meminimalkan waktu henti.

Spesifikasi Teknis yang Harus Anda Ketahui

Spesifikasi teknis perlu dievaluasi secara menyeluruh oleh teknisi dan manajer pembelian sehingga mereka dapat yakin bahwa mesin yang mereka pilih dapat memenuhi kebutuhan produksi saat ini dan di masa depan. Saat melakukan perbandingan model, penting untuk melihat parameter berikut ini:

- Kecepatan Pembatasan (BPM/BPH): Dinyatakan dalam botol per menit (BPM) atau botol per jam (BPH), ini adalah output teoretis maksimum mesin. Sangat penting untuk memilih mesin dengan kapasitas yang melebihi permintaan puncak Anda saat ini untuk memungkinkan pertumbuhan di masa depan.

- Jumlah Kepala Pembatas: Ini sebanding dengan kecepatan. Mesin dapat terdiri dari 3-4 kepala pada aplikasi rotari kecepatan rendah, dan hingga 24 kepala atau lebih pada lini minuman atau farmasi berkecepatan tinggi.

- Kisaran Ukuran Tutup dan Wadah: Setiap mesin dirancang untuk bekerja dalam kisaran diameter tutup dan tinggi/diameter wadah tertentu. Pastikan seluruh lini produk Anda dapat diproduksi dalam persyaratan ini, dan berikan produsen spesifikasi wadah dan dimensi tutup. Juga, tanyakan harga kemungkinan perlunya mengganti suku cadang (yang disebut suku cadang pengganti, seperti roda bintang dan cap chuck) untuk mengganti ukuran.

- Kebutuhan Daya dan Udara Terkompresi: Pastikan bahwa kebutuhan daya mesin (Voltase, Fase, Hz) dan jumlah udara (CFM/PSI) yang digunakan oleh mesin berada dalam batas-batas fasilitas Anda.

- Dimensi dan Jejak Mesin: Rotary cappers adalah mesin yang sangat besar. Periksa dimensi keseluruhan (panjang, lebar, tinggi) mesin untuk memastikan bahwa mesin tersebut dapat sesuai dengan tata letak lini produksi sebelumnya atau yang diinginkan.

Pembacaan yang cermat atas spesifikasi ini akan memungkinkan perbandingan langsung dan objektif antara produsen dan model, yang akan membantu Anda membuat keputusan akhir berdasarkan kriteria berbasis data.

Kasus Penggunaan oleh Industri: Dari Minuman hingga Farmasi

Mesin rotary capping sangat berharga dalam berbagai pilihan industri karena memiliki keserbagunaan dan kecepatan. Setiap industri menggunakan teknologi untuk memenuhi persyaratan produk dan peraturan.

- Minuman: Ini adalah pasar utama. Penutup putar cepat sangat penting untuk pembotolan air, minuman ringan, jus, dan minuman beralkohol, dengan tutup ulir sederhana dengan kecepatan 800 BPM atau lebih.

- Makanan dan Saus: Sistem putar digunakan untuk mengaplikasikan tutup lug/twist-off pada stoples kaca berisi saus pasta, salsa, dan selai, dan dapat dikombinasikan dengan teknologi penyegelan vakum. Mereka juga dapat digunakan dalam industri makanan ringan untuk menyegel stoples plastik berisi kacang-kacangan, pretzel, dan makanan kering lainnya. Mereka juga menangani tutup ulir bumbu, saus, dan minyak.

- Kosmetik dan Perawatan Pribadi: Sektor ini memiliki keragaman jenis penutup yang sangat besar yang digunakan. Rotary cappers dapat diprogram untuk bekerja dengan tutup pompa pada lotion, semprotan pemicu pada bahan pembersih, dan tutup ulir yang mewah pada krim dan serum kelas atas, di mana tidak hanya segel yang baik yang harus dibuat, tetapi penampilan juga penting.

- Obat-obatan: Ini juga merupakan industri yang sangat diatur di mana akurasi dan pencatatan sangat penting. Rotary cappers dapat menawarkan pengulangan torsi yang penting untuk penutupan tahan anak (CRC) dan segel anti rusak. Struktur baja tahan karat dan desainnya yang bersih membuatnya dapat digunakan di lingkungan yang steril dan bersih.

- Bahan kimia: Pada produk seperti pembersih rumah tangga, cairan otomotif, dan bahan kimia pertanian, penutupan yang aman adalah masalah keamanan. Rotary cappers memberikan torsi yang konsisten untuk memastikan bahwa penutup terpasang untuk mencegah kebocoran yang mengancam jiwa.

Tantangan Umum dan Bagaimana Rotary Cappers Mengatasinya

Teknologi rotary capping sering diimplementasikan oleh produsen sebagai solusi untuk tantangan tertentu yang tidak dapat diatasi dengan prosedur manual atau semi-otomatis. Tabel di bawah ini adalah ringkasan masalah yang paling umum dan bagaimana rotary cappers dapat menawarkan solusi langsung:

| Tantangan | Bagaimana Rotary Cappers Mengatasinya |

| Penyegelan yang tidak konsisten dan kebocoran produk | Kontrol torsi yang digerakkan oleh servo menerapkan torsi yang sama, yang telah diprogram sebelumnya ke setiap tutup, memastikan segel yang sempurna dan hampir menghilangkan kebocoran. |

| Kemacetan produksi dan hasil yang rendah | Desain gerak kontinu berkecepatan tinggi mengimbangi pengisi, menghilangkan kemacetan dan memaksimalkan output lini untuk memenuhi permintaan yang terus meningkat. |

| Biaya tenaga kerja yang tinggi dan cedera regangan yang berulang-ulang | Otomatisasi penuh mengurangi ketergantungan pada tenaga kerja manual, merealokasi staf ke tugas-tugas yang bernilai lebih tinggi, dan meningkatkan keselamatan di tempat kerja. |

| Tutup atau wadah yang rusak | Kontrol torsi yang presisi hanya menerapkan gaya yang diperlukan, melindungi penutup dan botol dari keretakan, pengupasan, atau perubahan bentuk. |

Bagaimana Memilih Mesin Rotary Capping yang Tepat

Menemukan rotary capper yang sempurna akan membutuhkan analisis yang cermat terhadap kebutuhan Anda sehubungan dengan fitur-fitur teknologi yang tersedia. Daftar periksa berikut ini akan membantu Anda membuat keputusan.

Tentukan Produk Anda (Saat Ini dan Masa Depan):

- Cantumkan semua jenis kontainer (bahan, bentuk, dimensi).

- Cantumkan semua jenis tutup (gaya, diameter, bahan).

- Pertimbangkan produk baru apa pun yang direncanakan untuk 3-5 tahun ke depan.

Tentukan Persyaratan Kecepatan Anda:

- Berapa BPM tertinggi dari pengisi Anda saat ini?

- Berapa kecepatan produksi ideal Anda?

- Berapa tingkat pertumbuhan Anda? Pilih mesin yang dapat memenuhi peningkatan kecepatan di masa depan.

Menilai Kebutuhan Teknis dan Kualitas Anda:

- Seberapa akurat torsi yang Anda butuhkan? Apakah cukup dengan kopling magnetik, atau diperlukan kontrol servo?

- Apakah ada kebutuhan industri tertentu (misalnya, baja tahan karat tingkat farmasi, kompatibilitas ruang bersih)?

- Berapa tingkat kerumitan pergantian Anda, dan berapa tingkat waktu henti yang dapat diterima?

Mengevaluasi Tingkat Otomatisasi:

- Apakah Anda memerlukan sistem yang terintegrasi dengan penyortir tutup dan lift, atau apakah hopper di lantai untuk memuat tutup curah dengan mudah sudah cukup?

- Tingkat kontrol/diagnostik apa yang Anda perlukan dari HMI?

Pertimbangkan Anggaran dan Total Biaya Kepemilikan:

- Hitung investasi modal awal.

- Tanyakan harga suku cadang pengganti berbagai produk.

- Tanyakan tentang layanan dan dukungan, pemeliharaan apa yang diperlukan, dan apakah ada suku cadang yang tersedia.

Dengan membahas poin-poin ini secara sistematis, Anda akan dapat mengembangkan dokumen persyaratan yang komprehensif. Hal ini akan membantu Anda melakukan negosiasi yang bermanfaat dengan pemasok peralatan dan membuat keputusan investasi yang tepat untuk mesin yang akan menjadi landasan operasi pengemasan Anda yang bermanfaat dan dapat diandalkan di tahun-tahun mendatang.

Di mana Mendapatkan Penawaran Mesin Rotary Capping

Mesin rotary capping yang tepat memilih mitra tepercaya. Levapack adalah produsen mesin capping profesional terkemuka di Cina dengan pengalaman lebih dari 15 tahun, pabrik modern seluas 4000 m 2, dan 300 pelanggan di seluruh dunia.

Jajaran screw cappers, snap cappers, dan rotary vacuum cappers kami sepenuhnya dirancang dan dibangun untuk menyertakan kontrol torsi servo terbaru, sistem kontrol PLC + HMI, pengumpanan tutup otomatis, dan perangkat keamanan tingkat tinggi. Setiap mesin diuji dengan 100+ kontainer dan periode tanpa beban selama 48 jam dan diperiksa secara menyeluruh untuk memastikan keandalan yang tahan lama.

Levapack mengintegrasikan baja tahan karat berkualitas tinggi (#304/316) dengan suku cadang dari merek-merek terkemuka dunia seperti Siemens, Schneider, dan SMC, yang menjamin daya tahan dan kepatuhan terhadap EC dan ISO. Solusi kami mampu melakukan pergantian yang cepat, desain khusus, dan sepenuhnya otomatis agar sesuai dengan aplikasi industri yang berbeda, membantu Anda memaksimalkan efisiensi, mengurangi biaya, dan melindungi integritas produk.

Hubungi spesialis Levapack sekarang untuk mendapatkan penawaran khusus tentang kebutuhan manufaktur Anda dan bagaimana sistem rotary capping kami dapat meningkatkan lini pengemasan Anda.

Jika Anda ingin tahu lebih banyak tentang produsen mesin capping, silakan baca artikel ini: 10 Produsen Mesin Capping Teratas: Solusi Otomasi

Kesimpulan

Pemilihan mesin rotary capping yang tepat merupakan keputusan penting terkait masa depan lini produksi Anda. Arsitekturnya yang terus bergerak dirancang untuk memecahkan hambatan kecepatan, sehingga menghasilkan keluaran tinggi yang diperlukan dalam manufaktur modern. Namun, nilai sebenarnya adalah menggabungkan kecepatan ini dengan presisi. Fungsionalitas tingkat tinggi, seperti kontrol torsi yang digerakkan servo, memastikan semua segel dapat diulang dan dapat diandalkan, memastikan integritas produk dan reputasi merek Anda. Dengan meluangkan waktu untuk memilih sistem yang akan berjalan sesuai dengan kebutuhan unik Anda, Anda tidak hanya membeli peralatan; Anda memasang solusi terbaik yang dapat memastikan efisiensi jangka panjang, kontrol kualitas, dan pertumbuhan yang dapat diskalakan di pasar yang kompetitif.